To

prevent thread jamming,

hold

both

thtead

ends

until

the

machine

has

made a few

stnctu~s.

Oo not

pull

lhe

material

during

sow

ing:

the

machine will feed the fabric automatically.

Use needles of tho correct system on

ly

(see Chapl

or

6).

Nover

use

cus

ty needles.

Usa high-qualily lhroads only.

Always

bring

the

take-up lever

10

itc

highest point before you remove

the

material.

3.

Cleaning and oiling

Caroful cleaning and reg

ular

oilirlg

will

increase t

he

sorvlce life or

your

machine.

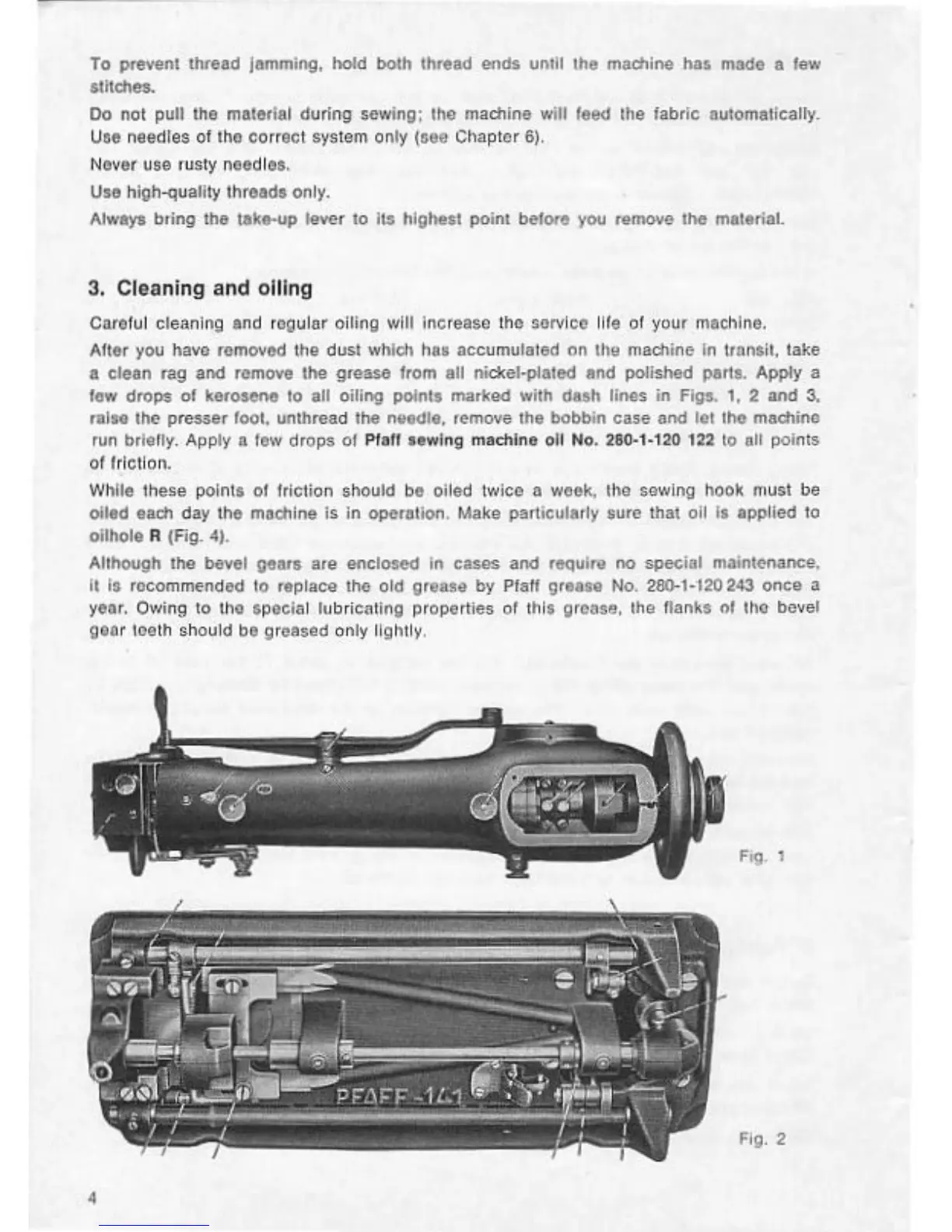

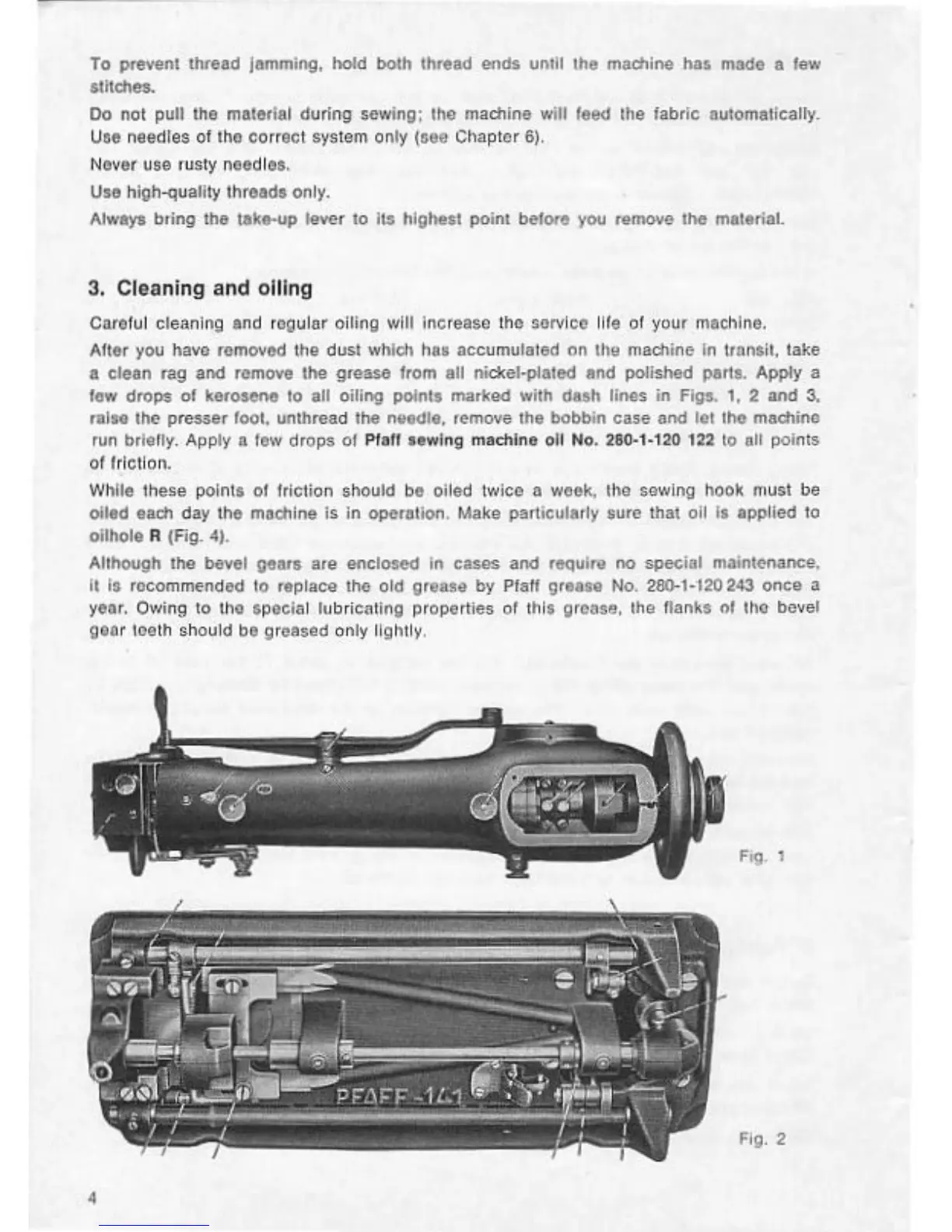

AHer you have removed the

dusi

which has accumulaled

on

the machine In trnnsit, take

a clean rag and

r~move

lhe grease from

all

nickel·plaled and polished parts. Apply a

fow

drops

of

kerose

ne

to

all

oiling

points

marked

with

dash

lines

in

Figs

. 1, 2

and

3,

ralso

the

presser foot. unthread the needle, remove the bobbin case and

let

tho machine

run brieny. Apply a few drops

of

Pfaff sewing machine oil No. 280·1·120 122

to

nil

points

of frlcllon.

White 1hese point$ ol friction should be oiled twice a woek, the sewing hook must be

oiled

each day

tho

machine

is

in

operation. Make particularly sure that oil Is applied

to

oilhole R (Fig. 4).

Although

the

bevel gears are enclosed

in

cases and reQuire

no

special mainteneoce,

It

is

recommended

to

replace the

old

grease

by

Pfaff grease No. 2S0.1-120 243

once

a

yeor.

Owing

to

tho spacial

lu

bricating properties

of

this grease. the flanks

nt

tho bevel

geor tooth should bo greased only llghlly.

Fog 1

Fig. 2

4

Loading...

Loading...