7

Installation

Fitting sequence

Please refer to the following pages for accompanying installation diagrams.

When positioning the lift into the vehicle:

1. Roll off ramp (wheels) must be clear of rear doors, minimum 15mm.

2. When the lift is powered “down” the bridge plate mechanism must be clear

of the rear bumper or side valence.

3. The distance between the inside of the door aperture and the outside

of the handrails should be equal both sides.

4. All manual override systems must be fully accessible.

5. The vehicle surface MUST be flat. Do not attempt to mount base plate on top of seat

tracking extruded sections. Shim base plate above tracking if necessary.

If the surface is not flat, when the lift is bolted down the base could distort to the

contours of the floor. This will have the effect of altering the position of the lifting arms,

thus twisting the lift.

THIS WILL AFFECT PRODUCT WARRANTY.

When bolting in the base:

1. PLS universal fitting plates should be used instead of washers!

2. At least two of the front bolts (closest to driver) should be located through the

vehicles chassis.

NB. WHEN FITTING EAB A “FULL” REAR BEAM MOUNTING BRACKET SHOULD

BE USED.

Adjusting lift:

1. Ensure vertical stow position is set correctly.

2. Ensure horizontal platform position is set correctly.

3. Ensure roll-off ramp end of platform lands on ground first.

4. Ensure platform is symmetrical (not twisted)

5. Ensure Platform gates are locating together correctly.

6. To correctly adjust the Platform Knuckles see Platform Gates “Synchronizing”

Procedure in section 7.4

To Finish:- Weight Test Lift to current LOLER recommendation/ regulations.

1. Check all fitting bolts are tightened to correct torque setting.

2. Check all lift fastenings are tight.

3. Ensure all information decals are positioned correctly.

4. Lift serial number and SWL are visible.

5. Fill in weight certificate.

6. Fill in LOLER certificate.

7:2 General Installation Access™ EA & Access™ EAB

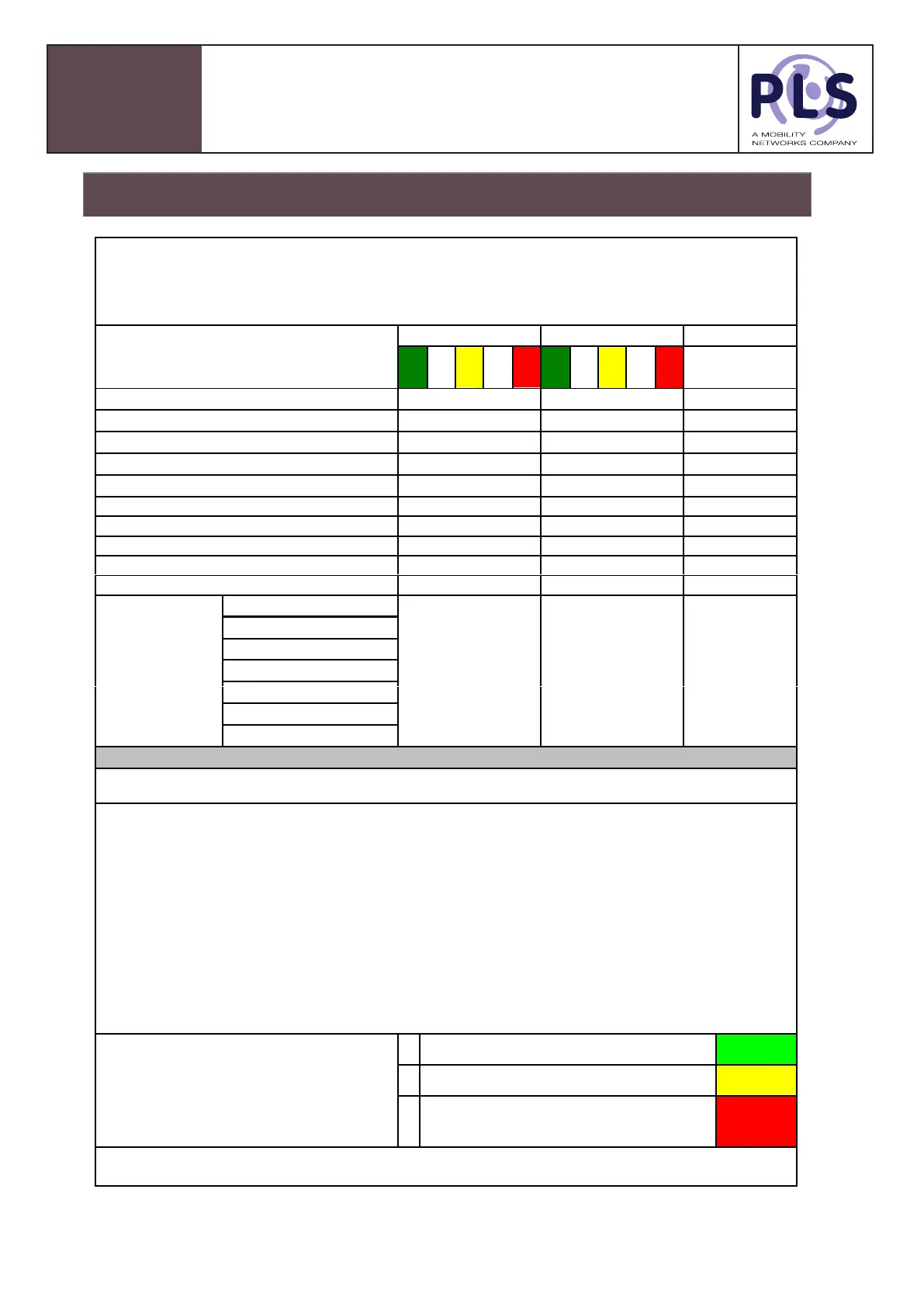

7.1 General Installation- Risk Assessement Access™ EA & Access™ EAB

Location:PassengerLiftServicesLtd

Operation/Activity:LiftOperation

Listbelowtheoperations,inyour

opinion,whichinvolveasignificant

Stabilityofliftduringoperation

Entrapmentfrommovingparts

Manualoperationoflift

Contactwithhazardoussubstances

Noinjuryjustminordamageto

plant,equipmentorstructure

Listpersonsat

Operators

Minorinjury–smallcutorbruise

Rare-mayoccuronlyin

exceptionalcircumstances.(0-

20%chance)

Serious–medicaltreatment

required–doctororsmallinjury

Moderate-couldoccurat

sometime.(41-60%chance)

Major–attendanceathospital

Likely-notsurprisedcouldoccur

severaltimes.(61-80%chance)

Certain-tobeexpected,will

occurrepeatedly.(81-100%

Riskratinghasbeendefinedtakingintoaccountthefollowingcontrolmeasures

Controlmeasuresinclude(engineeringqualitycontrol,specialistequipmentinformation/instruction,Customer

responsibilitiesmaintained.

ActionPlan/Controls:-

Allliftsaresuppliedwithsafetyinstructionsandsafeoperatingprocedureswithvisualinstruction

fortheautomaticandmanualoperationoflifts.

Safetyinstructionisalsogeneratedandsuppliedfortheuseofliftsbyscootersandlargepowered

Supplyandfittedliftshaveaweighttestcertificateandaninstallationandexaminationreport

completedbyacompetentengineercomplyingto;LiftingOperationsandLiftingEquipment

Additionalcontrolsaretobeimplementedandmaintainedbytheenduser,withsixmonthly

inspectionscarriedoutonallliftingequipmentconformingto;LiftingOperationsandLifting

EquipmentRegulations1998.

HastheoverallriskratingbeenreducedtoLow?

Controlsaredeemedadequate-proceedwiththe

Hastheoverallriskratingbeenreducedto

Consideradditionalcontrols,strictmonitoringof

controlsrequired-proceedwithcaution

Operation/activityisNOTtobeundertakenuntil

HastheoverallriskratingremainedHigh?

additionalcontrolshavebeenimplemented-contact

Cantheriskbereducedtolowbyintroducing

additionalpreventativeand/orprotectivemeasures?No

SeeRiskAssessmentActionPlanforadditionalprecautions/controlstobeimplemented.

Assessmentcarriedoutby:

REMEMBER:REVIEWTHEASSESMENTIFTHECIRCUMSTANCESCHANGESIGNIFICANTLY

7.1 Gen e ral In s tal l ati o n- R isk Ass e ssm e nt A cce s s™ E A &

Acc e ss™ EAB

Loading...

Loading...