Circuit breaker tripped/ Fuse

Blown

Re-set circuit breaker (push button in) situated on vehicle

or change fuse.

Check wiring inside handset or change module

Replace damaged or stretched springs.

Arm linkage has seized in

Press the down button whilst pulling lift out. Note: must

stand clear of platform.

Platform unfolds when not in use

Hose burst/ hydraulic leak

Check for leaking oil, replace all necessary components

Close tap and re-stow lift

Manual override tap left open/

down valve manual override

opened

Close “red” down valve tap and re-stow lift.

Re-set circuit breaker (push reset button in) situated near

to vehicle battery

Hose burst/ hydraulic leak

Check for leaking oil, replace necessary components

Low oil level in reservoir

drawing air into system

Top up reservoir with PLS BLUE hydraulic oil, 25mm from

top “max” (when lift is completely stowed)

Platform doors do not align

Replace damaged components.

Platform Knuckles not set

correctly

Adjust Platform Knuckles at platform pivot. Note: when

platform is down the Platform Knuckles must NOT be over

tensioned. i.e. can turn via finger pressure

See Platform Frame “Horizontal” Adjustment Procedure 7.3

See Platform Gates “Synchronizing” Procedure 7.4

Roll-off ramp not reaching floor.

NOTE. Keep fingers on DOWN

Button.

Spray all pivots and moving parts with ACF-50

Land the lift on a more suitable surface

Adjust stowage adjustment screws at base of platform to

set level position.

Bridging plate not dropping to

base plate

Lift not raised to max up

position

Power lift UP fully to floor height

Mechanism requires adjusting

Re-set and test bridge plate mechanism

Replace damaged components

Adjust stowage adjustment screws at base of platform to

set level position

See Platform Frame “Horizontal” Adjustment Procedure 7.3

See Platform Gates “Synchronizing” Procedure 7.4

Activation spring has lost

tension

Bridge plate hinge has jammed

Loosen and re-lubricate/ replace parts as necessary.

Bridging plate not returning to

vertical position

Mechanism has stuck in down

position

Re-set, lubricate and test bridge plate mechanism

Gas strut has lost pressure

Replace parts as necessary.

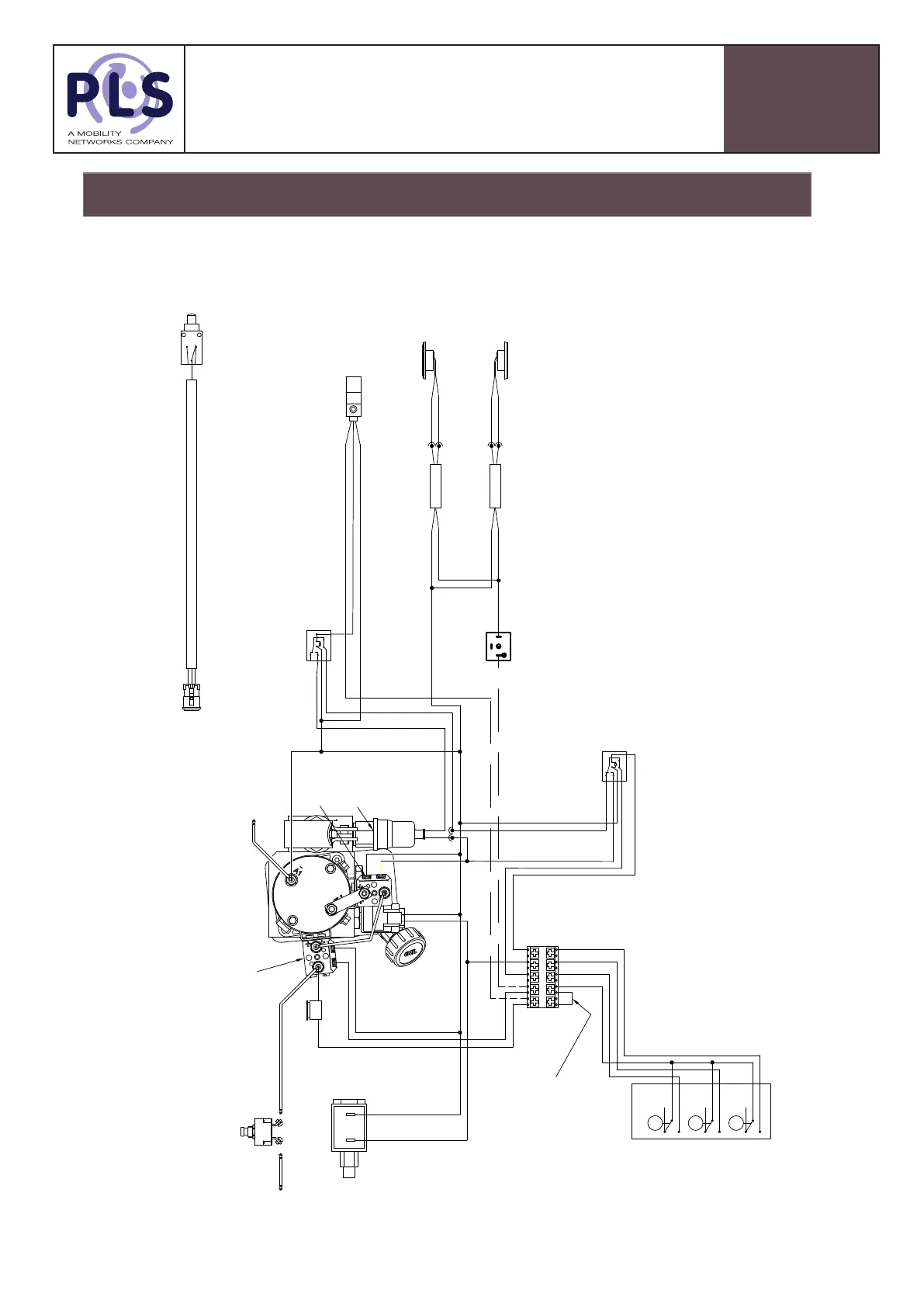

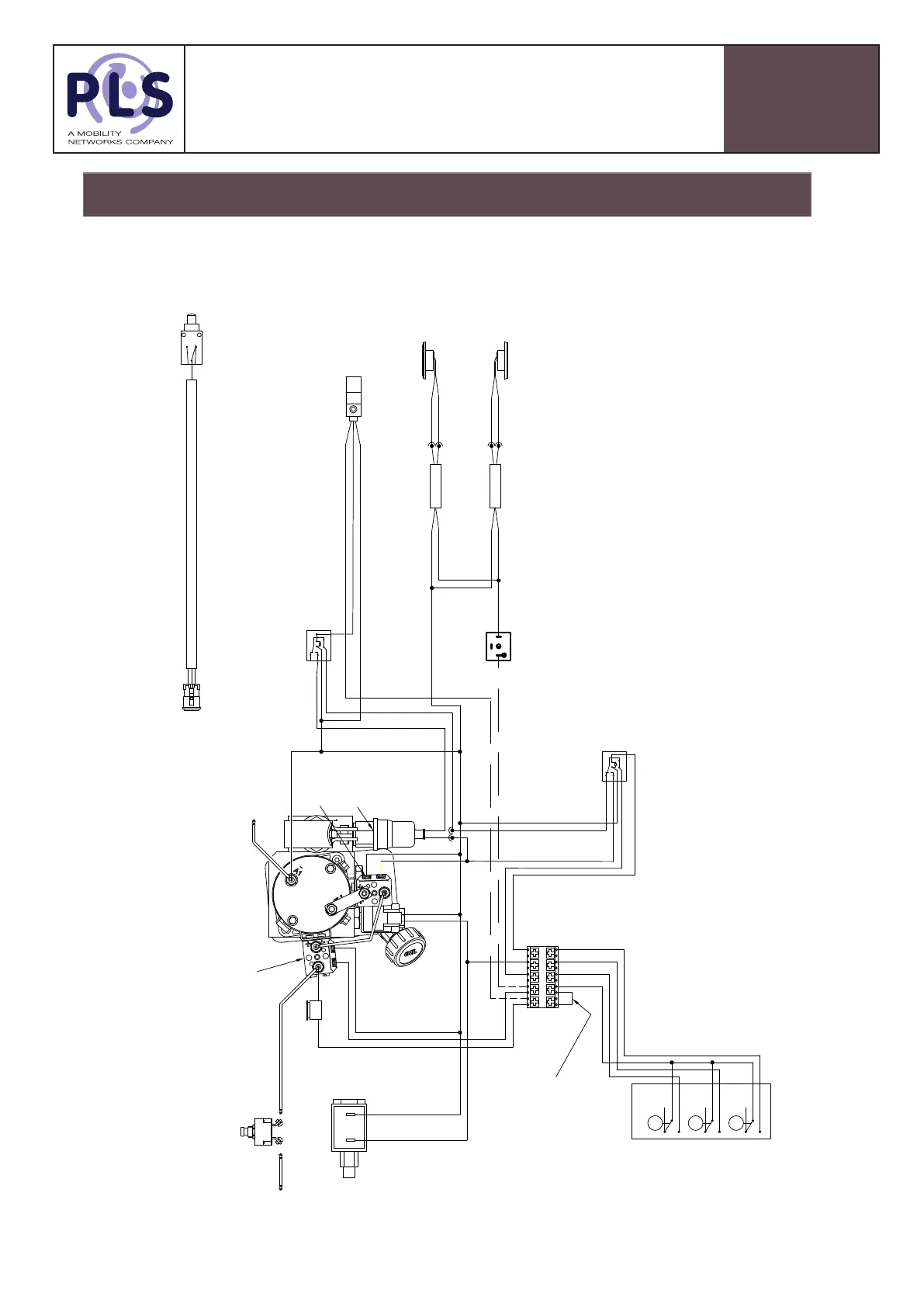

12.1 Troubleshooting Instructions Access™ EA & Access™ EAB

Diagrams

13.1 Wiring Diagram - Power Pack - 3 Options Access™ EA & Access™ EAB

Wiring Diagram- “Standard”

13.1 Wiring Diagram- Power Pack- 3 Options Access™ EA & Access™ EAB

SIDE LED LH

(OPTIONAL)

SIDE LED RH

(OPTIONAL)

DOWN=BLUE

STOW=YELLOW

UP

DOWN

STOW

3 BUTTON HANDSET

NC

COM

NO

NC

COM

NO

NC

COM

NO

1

2

RED

BLACK

2

1

1

2

RED

BLACK

2

1

STOP SENSOR

(OPTIONAL LOW PRESSURE

LIFTS)

FLASHER RELAY

(OPTIONAL)

UP=BROWN

LIVE=BLACK

BK

BN

YE

BL

RD

STOP RELAY

(OPTIONAL LOW PRESSURE

LIFTS)

STOW RELAY

SECONDARY DOWN VALVE

(OPTIONAL)

FUSE

10A

16mm

NEGATIVE

BATTERY CABLE

STARTER

SOLENOID

PRESSURE

SWITCH

ISOLATION SOLENOID

16mm

POSITIVE

BATTERY CABLE

12-24VDC

REMOVE LINK DURING INSTALLATION

BEFORE FITTING CAB/ DOOR SWITCH.

BN

RD

BL

BN

YE

BK

P

YE/RD

YE

BN

BN

BL

RD

BL/WH

BK

BN

BL

STOW WARNING SWITCH (BACK OF BOX)

THIS MICRO SWITCH IS USED TO SIGNAL WHEN THE LIFT IS

IN & OUT OF STOW. IT CAN BE USED TO SIGNAL A

WARNING LIGHT OR BUZZER ON THE DASHBOARD.

IT SHOULD NOT BE HARDWIRED TO THE VEHICLE BRAKES.

A

B

C

BU (NO)

BN/BK1 (COM)

BK2 (NC)

BLUE (NO)

BROWN (NO)

BLACK 1 (NC)

BLACK 2 (NC)

CIRCUIT BREAKER

12V=70A

24V=40A

2

1

S

U

D

S

C

13

Loading...

Loading...