GP44 Semi-Automatic Strapping Machine

OPERATION -29-

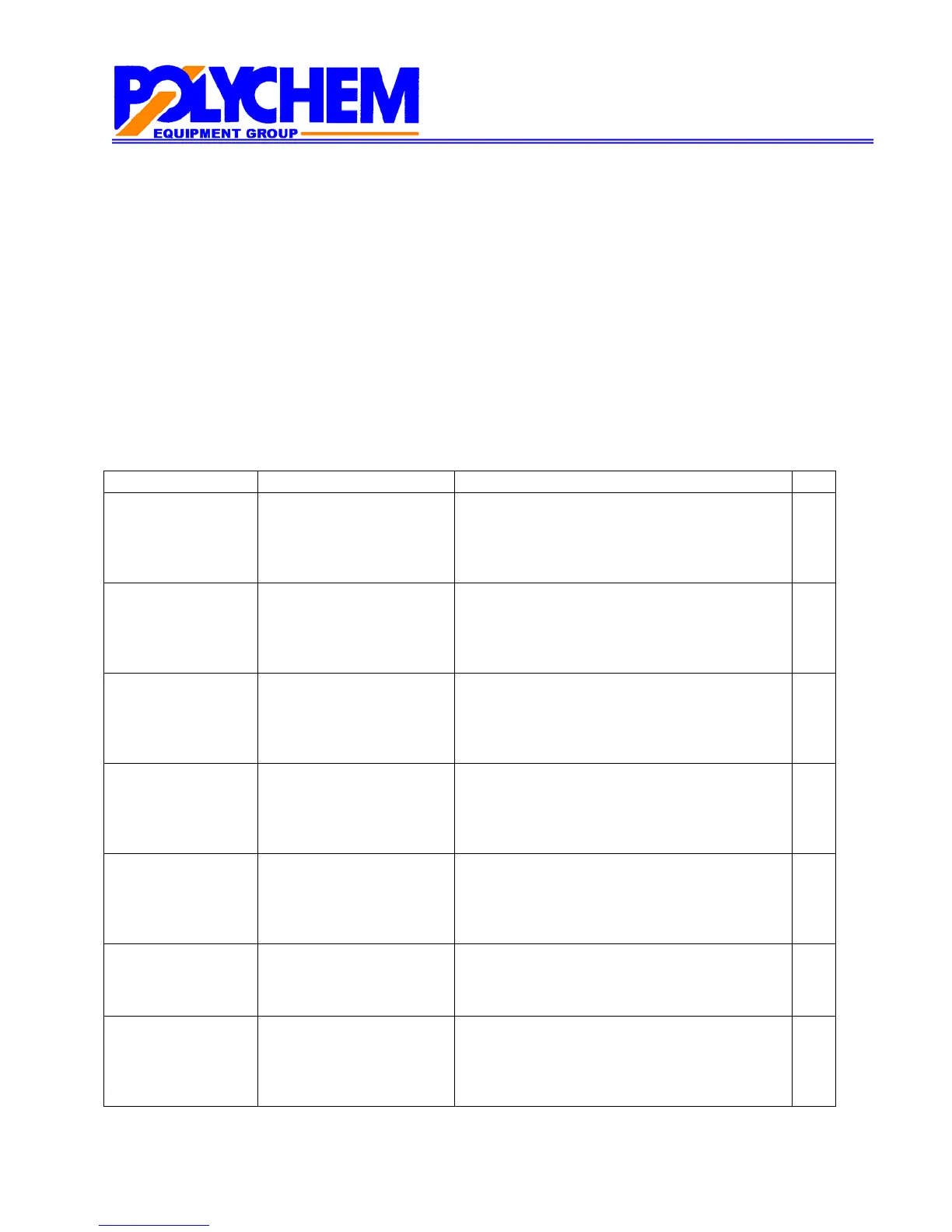

Release Tension, Cut and Weld

NOTE: The sequence that these functions take place is that as the controlled tension is completing, the left

gripper extends to hold the tension that has been created. As the middle gripper extends to compress the two

layers of strap against the heater blade, the middle gripper shears the strap against the right gripper. After the

heater blade retracts, the middle gripper compresses the two layers of strap against each other to create the

weld.

When troubleshooting welding problems, check the appearance of the strap for evidence of contact by the

heater blade. This can be used to determine if the problem is that the heater blade is interfering and not

making it in between the strap or if the problem is elsewhere.

NEVER BEND THE HEATER BLADE WHEN IT IS COLD. THE HEATER BLADE MAY CRACK.

Symptom Cause Solution GP

The weld is

breaking and there

is no evidence of

full heater blade

contact on the strap

The heater blade is bent

or the bracket is out of

position and the heater

blade is not extending

between the straps.

Cycle the cam by hand and determine the

cause of the interference. Eliminate the

cause of the interference. Realign heater

blade and heater tower.

X

The weld is

breaking and there

is evidence of

proper contact with

the heater blade

The middle gripper is not

applying adequate

pressure to seal the

melted strap

Shim middle gripper per specification

X

The weld is

breaking and there

is evidence of

proper contact with

the heater blade

The left gripper is not

adequately gripping the

strap and allowing

movement during the

welding cycle

Shim left gripper per specification

X

The weld is

breaking and there

is evidence of

proper contact with

the heater blade

The seal anvil is cracked

or bent which is not

allowing proper

compression by the

middle gripper.

Replace the seal anvil. Re-shim the grippers

when replacing the seal anvil. Over

shimming the grippers is a typical cause of a

cracked seal anvil, therefore, they should be

checked when a seal anvil is detected.

X

The weld is

breaking and there

is evidence of

proper contact with

the heater blade

The heater blade is not

providing adequate heat.

Check heater blade, insulation and wiring.

Look for discontinuity in this circuit. Check

heater blade for build-up. Check the heater

control voltage (100V). Adjust the heater

blade tap to a lower letter.

X

The cut is not clean The left gripper is not

adequately gripping the

strap during the cutting

operation

Shim left gripper per specification

X

The cut is not clean The cutting surface on the

middle gripper is not

sharp or there is not tight

contact between the

middle and right gripper

Replace the middle gripper. Make sure the

spring holding the middle and right gripper

together is intact. X

Loading...

Loading...