Why won't my Pompetravaini Water Pump start?

- KKenneth RayAug 3, 2025

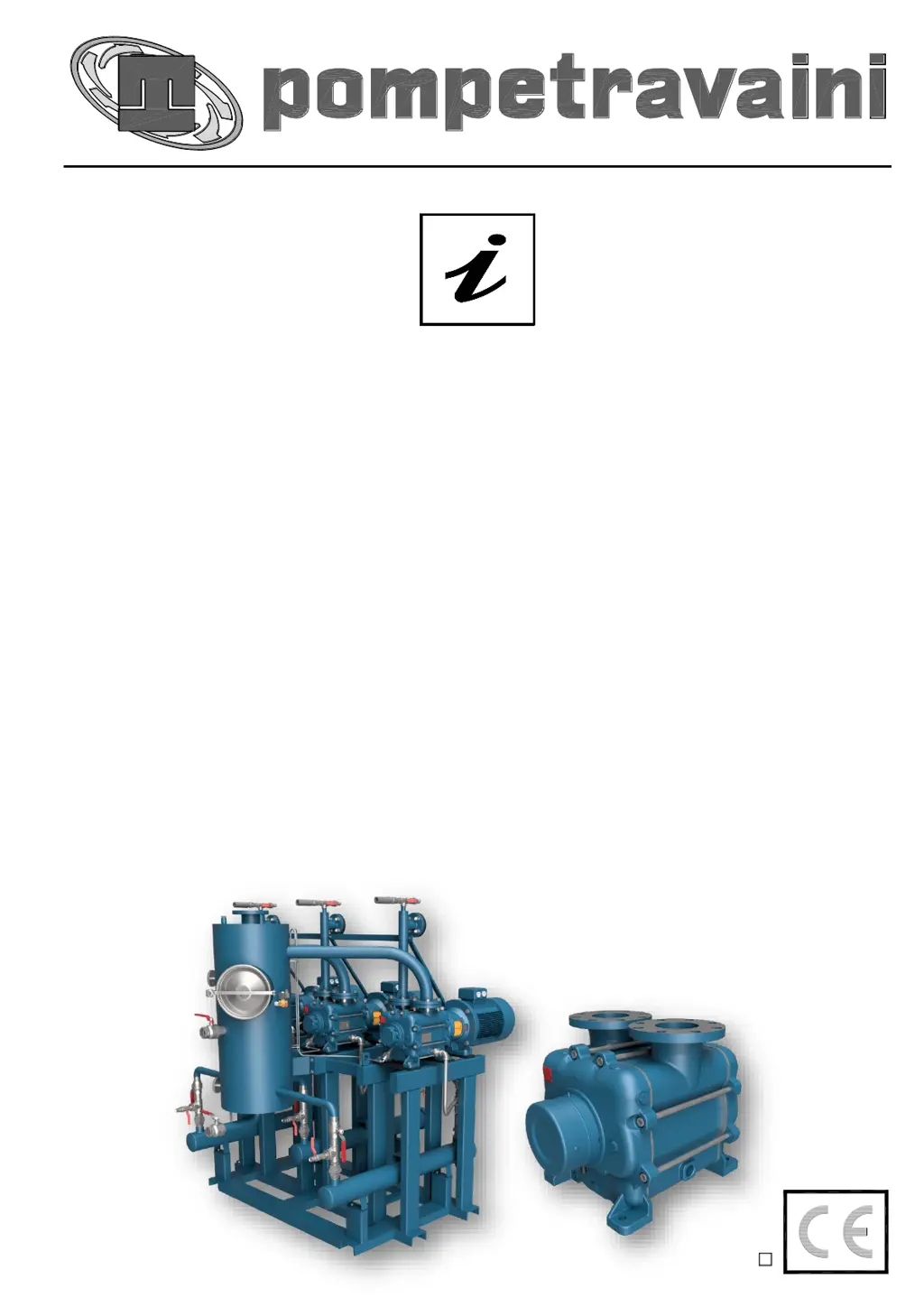

If your Pompetravaini Water Pump isn't starting, the issue might stem from a defective motor or incorrect wiring. To address this, verify the voltage, frequency, motor type, power consumption, rotation, wiring connections, and phase consistency.