76

Eagle_en_Ver.1.0_2020

Adjustment / Test

J

Unloader adjustments

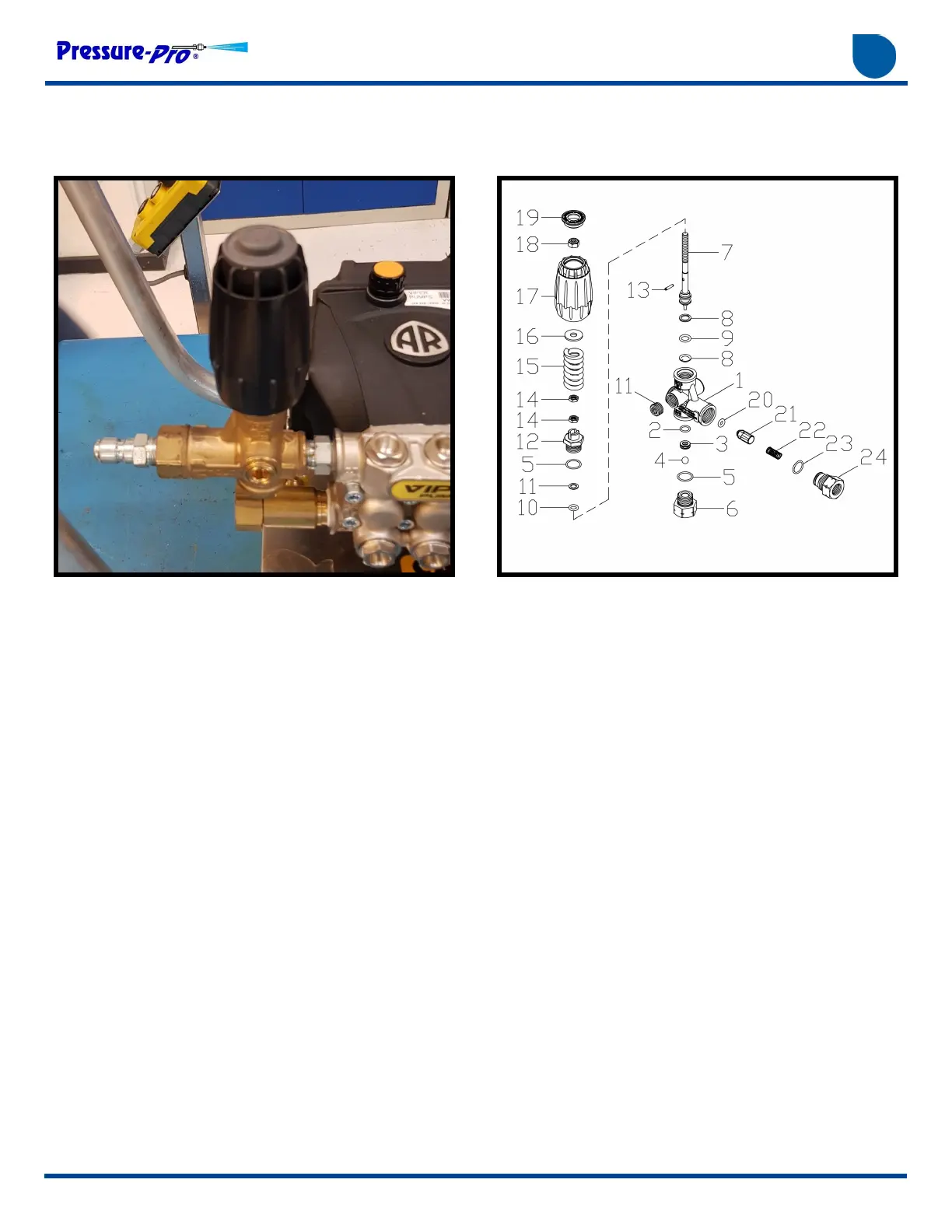

VRT3-310EZ UNLOADER

Adjustment procedure for Unloader.

Install test pressure gauge with fully open valve on the pump outlet.

Install high pressure hose, gun and lance with new high pressure nozzle on the test pressure gauge.

Turn the black handle clockwise all the way to the stop.

Start machine with fully open gun.

Adjust to specified pressure on adjustment screws (pos. 14, Fig. 2). Read pressure on test manometer.

(For adjustment on the adjustment nuts (pos 14, Fig. 2).

Stop the engine, dismount pos. 19, pos 18 and pos. 17. For dismounting pos. 17 turn it all the way

Counterclockwise. Dismount pos. 16 and pos. 15. Now you have access to the adjustment nuts.

When the pressure is correct adjusted, tighten counter nut (pos. 14, Fig. 2), and mount pos.15, 16, 17,

18 and 19.

Nut pos. 18, must be turned clockwise until the threads are alligned with the top surface of the nut. DO

NOT TURN IT ALL THE WAY DOWN.

For products with a data sheet* find the correct test values with tolerances in the product data sheet.Data is to

be found in the Technical Data. See section ”B”

For older products without data sheet use the below general rule.

Pressure Under Load (With Trigger Pulled And Correct Nozzle) Should Match Factory Specified Pressure.

No Load Pressure Should Not Be In Excess Of 10% Of Working Pressure**.

**Example : 4000 PSI in Bypass + 10 % Should Not Exceed 4400 PSI

Fig. 1 Fig. 2

Loading...

Loading...