31 © 2017 Proceq SA

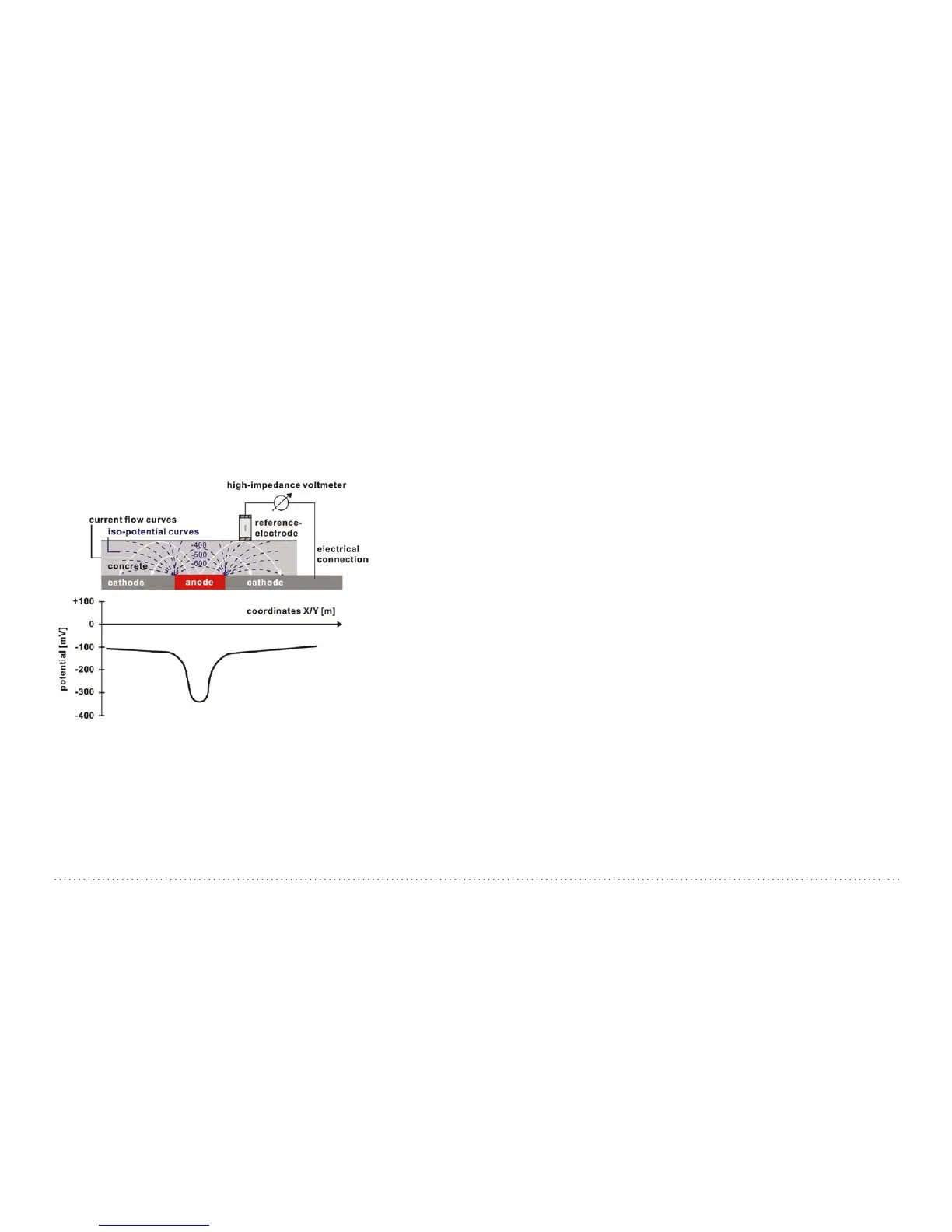

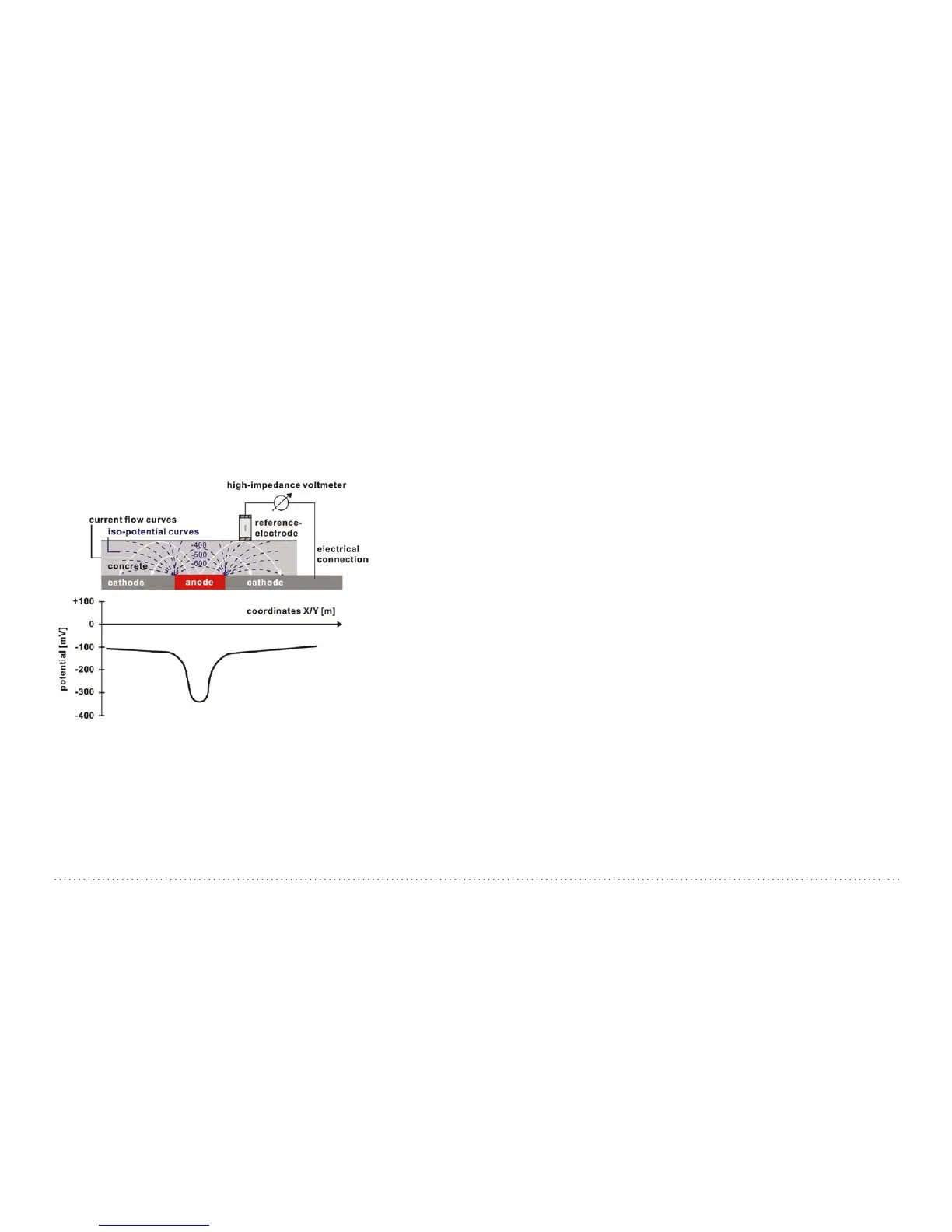

The basic idea of the potential field measurement is to measure the po-

tentials at the concrete surface, in order to get a characteristic picture of

the state of corrosion of the steel surface within the concrete. For this

purpose a reference electrode is connected via a high-impedance volt-

meter to the steel reinforcement and is moved in a grid over the concrete

surface.

The reference electrode of the Profometer Corrosion system is a Cu/

CuSO

4

half-cell. It consists of a copper rod immersed in a saturated cop-

per sulphate solution, which maintains a constant, known potential.

Figure 35:

Measuring Principle

4.1.2. Typical Potential Range

Typical orders of magnitude (for information only) for the half-cell poten-

tial of steel in concrete measured against a Cu/CuSO

4

reference elec-

trode are in the following range (RILEM TC 154-EMC):

• water saturated concrete without O2: -1000 to -900 mV

• moist, chloride contaminated concrete: -600 to -400 mV

• moist, chloride free concrete: -200 to +100 mV

• moist, carbonated concrete: -400 to +100 mV

• dry, carbonated concrete: 0 to +200 mV

• dry, non-carbonated concrete: 0 to +200 mV

In general terms the probability of corrosion rises with low (negative) po-

tentials; active corrosion can be expected at locations where a negative

potential is surrounded by increasingly positive potentials, i.e. locations

with a positive potential gradient. Potential differences of around +100mV

within a 1m measurement area, together with negative potentials can be

a clear indication of active corrosion.

The actual potential absolute value (corrosion threshold) below which ac-

tive corrosion can be expected may vary significantly on different struc-

tures. It is however useful to mention the thresholds suggested by ASTM C

876-09, Appendix X1, assigning a 90% probability of corrosion ongoing to

the areas more negative than -350 mV, and a 90% probability of no corro-

sion to the areas more positive than -200 mV, judging uncertain the behav-

ior in the regions in between the two thresholds. Be sure to note the con-

ditions stated by ASTM as to the applicability of these threshold values.

4.1.3. Factors affecting the Potential Measurement

Provided that the corrosion conditions are equal (chloride content or car-

bonation of the concrete at the steel surface) the main influences upon

the half-cell potentials are:

Moisture

See the chart above for moist, carbonated concrete and dry, carbonated

concrete. Moisture has a large effect on the measured potential leading

to more negative values.

Loading...

Loading...