Reversing Cutter:

A feature of this machine is that the cylinder may be easily removed, reversed end for end

and replaced. This provides a new keen cutter edge. If the bottom blade is badly worn, this

should be replaced at the same time that the cutting cylinder is reversed or replaced.

To withdraw cutter from machine, first remove cutter chain (7), sprocket (8) and grass

deflector (9), refer illustration PAGE 1. The sprocket is removed by inserting tommy bar in

hole in sprocket and giving tommy bar a sharp tap with hammer, NOTE: The sprocket has a

left hand thread, to unscrew, turn in a clockwise direction. Remove the grass deflector

and the deflector-supporting bar. Remove the cutter hanger caps by undoing the holding

bolts (10) at each side of the machine. Then the cutter may be taken from the machine by

lifting and moving to the chain side of the machine. The opposite side will then clear side

frame. Continue with a diagonal lift to complete removal. Remove the nut from the end of

the cutter (it has a left hand thread). Reposition this nut at the other end of the cutter. Turn

the cutter end for end and replace in the machine. Then reverse operations used to remove

cutter from machine. Replace all bolts and tighten firmly. After reversing cutter it will be

necessary to adjust the same. Also see detail on chain adjustment

Important:

When reversing or replacing the cutter do not remove the cutter bearing

hangers. Remove the bearing caps only as instruction. The bearing caps

must not be changed over; each cap must be replaced in its original

location.

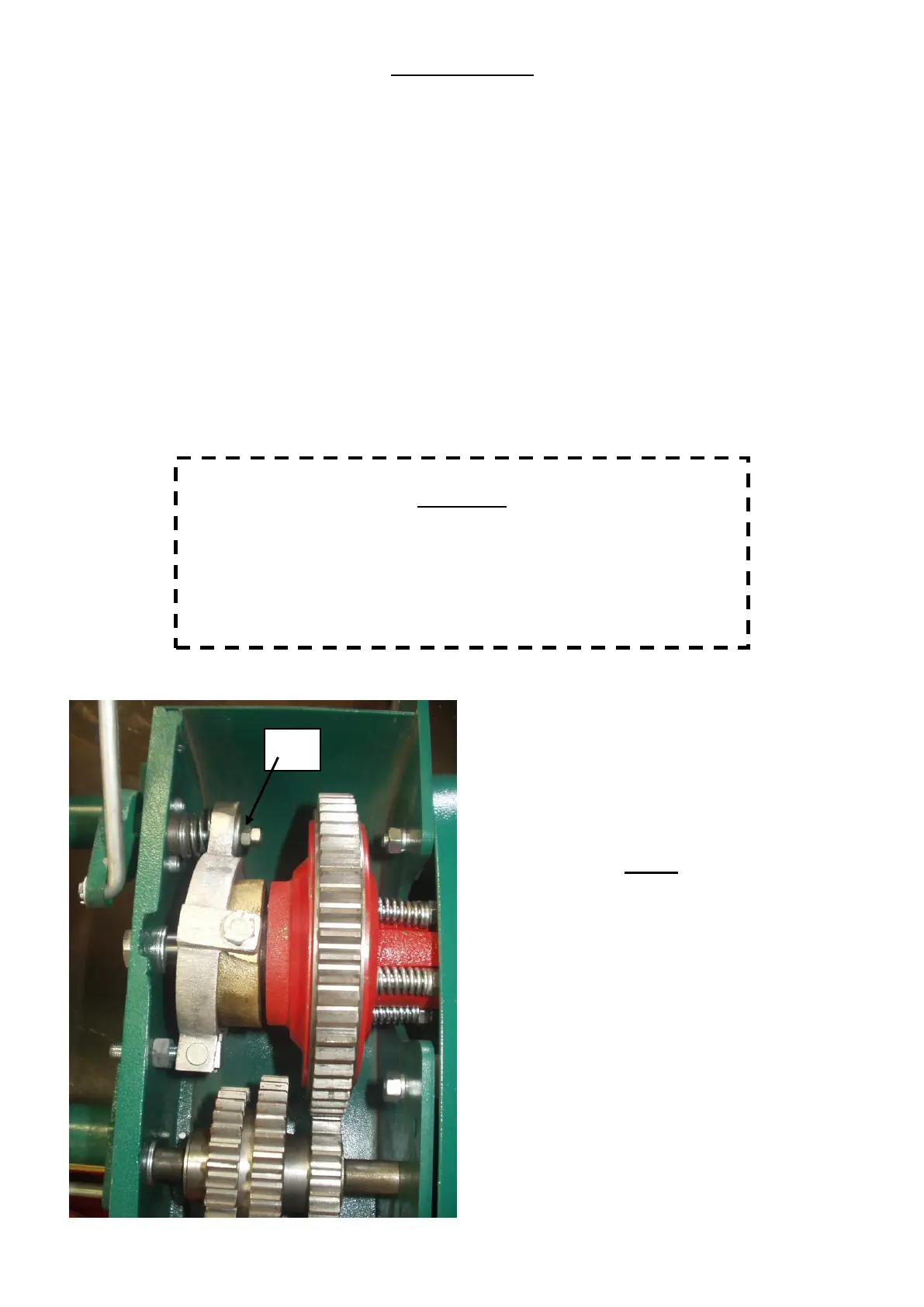

Clutch:

To be certain that the clutch is fully

engaged without possibility of slip, there

should be approximately 1½” of free

movement (at the clutch operating lever

knob) before the resistance of clutch

operation is felt. This adjustment is made

by means of the self-locking nut “E”

Loading...

Loading...