3 4

AIR SOURCE

Clean air of correct air pressure is recommended for the power supply

for this tool. A maximum of 90 PSI at the tool is recommended for most

air tools of this class. Check specifications section for recommended

pressure. (Depending on length of air hose and other circumstances, air

pressure at compressor may need to be increased to 100 PSI to ensure

90 PSI at the tool.)

Water in the air hose and compressor tank contributes to reduced

performance and damage of the air tool. Drain the air tank and filters

before each use and as necessary to keep the air supply dry.

Hose length over 25’ causes loss in line pressure. Increase hose I.D. or

increase compressor pressure to compensate for the pressure loss. Use

an in-line pressure regulator with gauge if air inlet pressure is critical.

OPERATION

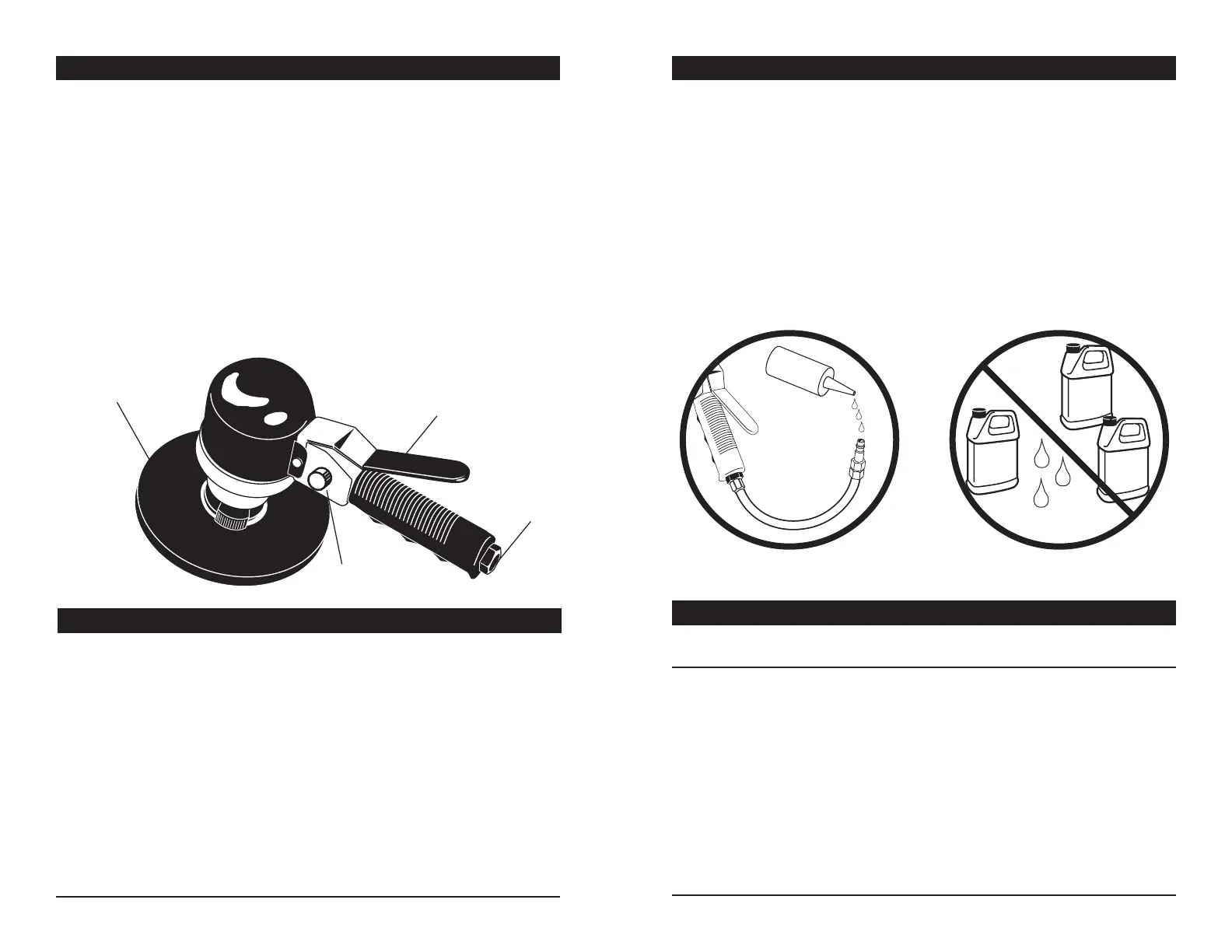

1. Regulate pad speed with air regulator knob.

2. Start the sander off the sanding surface. Set the sander on the

surface gently and evenly and start the work. Let the sander do the

work. The weight of the sander will provide efficient sanding.

Applying pressure to the sander will only slow the speed of the pad

and reduce sanding efficiency. This will also overload the motor and

cause premature wear of the tool and void the warranty.

3. Work the sander back and forth in a wide, overlapping motion. Lift

the sander off the surface before releasing the trigger.

4.

Start with a paper grit coarse enough to remove high spots and rough

areas. Continue using progressively finer grit to attain desired finish.

Sanding pad

Air regulator

Trigger

Air Inlet

Motor

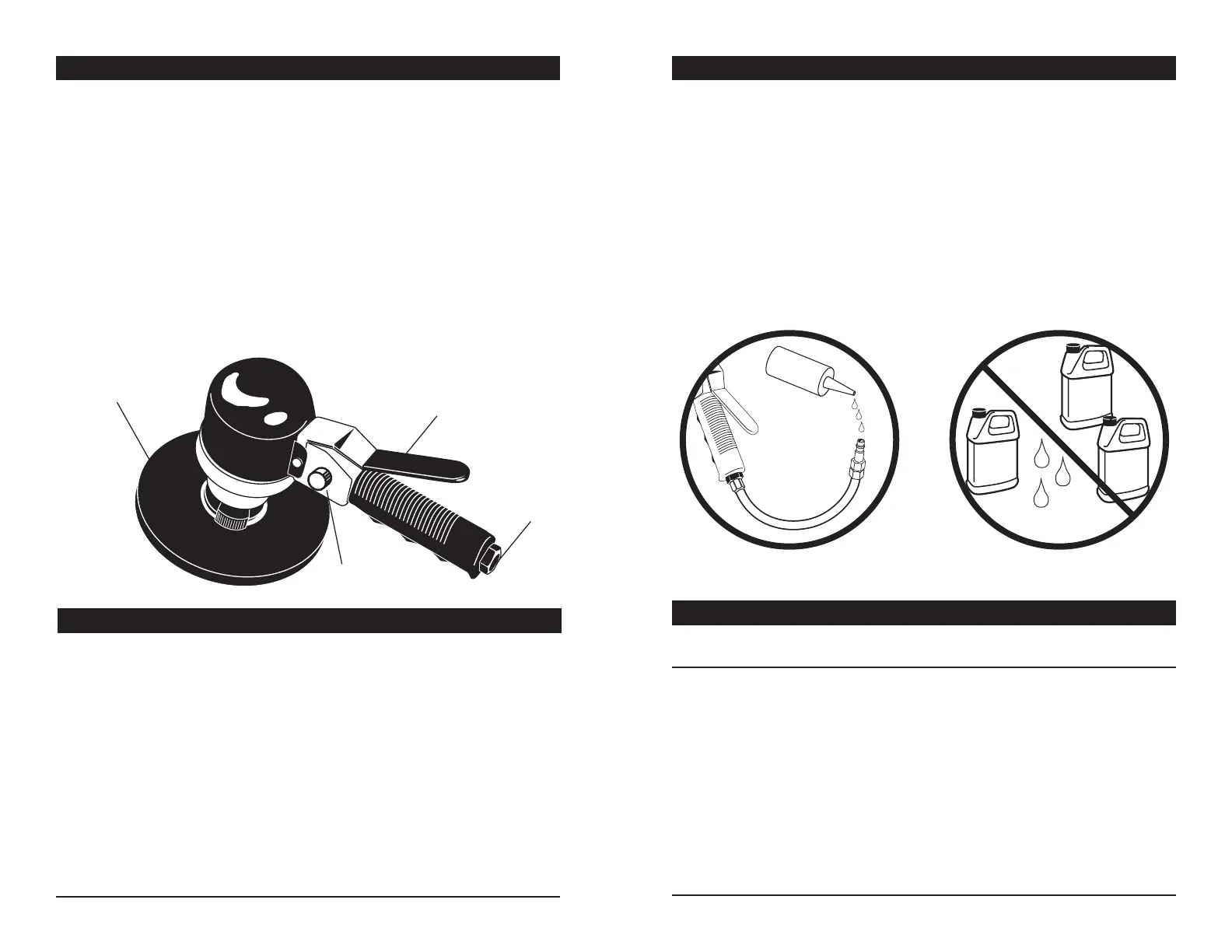

Oil

Trans.

Fluid

Brake

Fluid

Water

Whip

hose

Air Tool

Oil

Oil tool before each use. 4 to 5 drops of a good grade Air Tool

Oil placed in the air inlet is sufficient. Use proper air pressure and

CFM rating listed for this tool.

Drain water from hoses and compressor tank. Water in the

air supply line will cause gumming and loss of power. Clean the

air lter on the supply line and ush the tool with gum solvent or

a 50/50 mix of air tool oil and kerosene. It may be necessary to

disassemble the tool to properly clean and re-lubricate.

LUBRICATION & MAINTENANCE

TROUBLESHOOTING

INSUFFICIENT POWER:

Probable Cause Solution

Dirty or clogged air passages......... Flush and lubricate tool, drain air tank and supply line

Insufficient air supply ...................... Increase line pressure, Make sure compressor

matches tool’s air pressure and consumption needs

Air leakage ...................................... Use teflon tape at all fittings and joints. Check tool for

worn or damaged O-rings & seals.

Worn/damaged wear & tear parts .. Replace as necessary.

Tool matching ................................. Be sure you are using a tool suited for the torque

requirements of the job at hand.

Loading...

Loading...