Gauges: .............................................................2-1/2 in. diameter, rubber protected

PSI Gauge: .............................................................. 0 to 100 PSI (2 psi increments)

Cylinder Leakage Gauge: ................................................... 0-7 Bar (0.2 increments)

Maximum Inlet Pressure: ............................................................................... 100 psi

READ AND UNDERSTAND ALL INSTRUCTIONS

Failure to follow all instructions detailed in this manual may result in serious personal injury.

SAVE THESE INSTRUCTIONS

• Keep your work area clean and well lit. Cluttered and dark work areas invite accidents.

• Stay alert. Watch what you are doing, and use common sense when operating tools and equipment. Do not

assemble or use this product while tired or under the influence of drugs, alcohol, or medication. A moment

of inattention while operating tools and equipment may result in serious personal injury.

• Wear eye protection. Wear ANSI-approved safety impact glasses and full face shield when using this product.

• Do not force the Leakdown Test Kit. Use the correct product for your application. The correct product will

do the job better and safer at the rate for which it is designed.

• Maintain the Leakdown Test Kit with care. Keep this product clean.

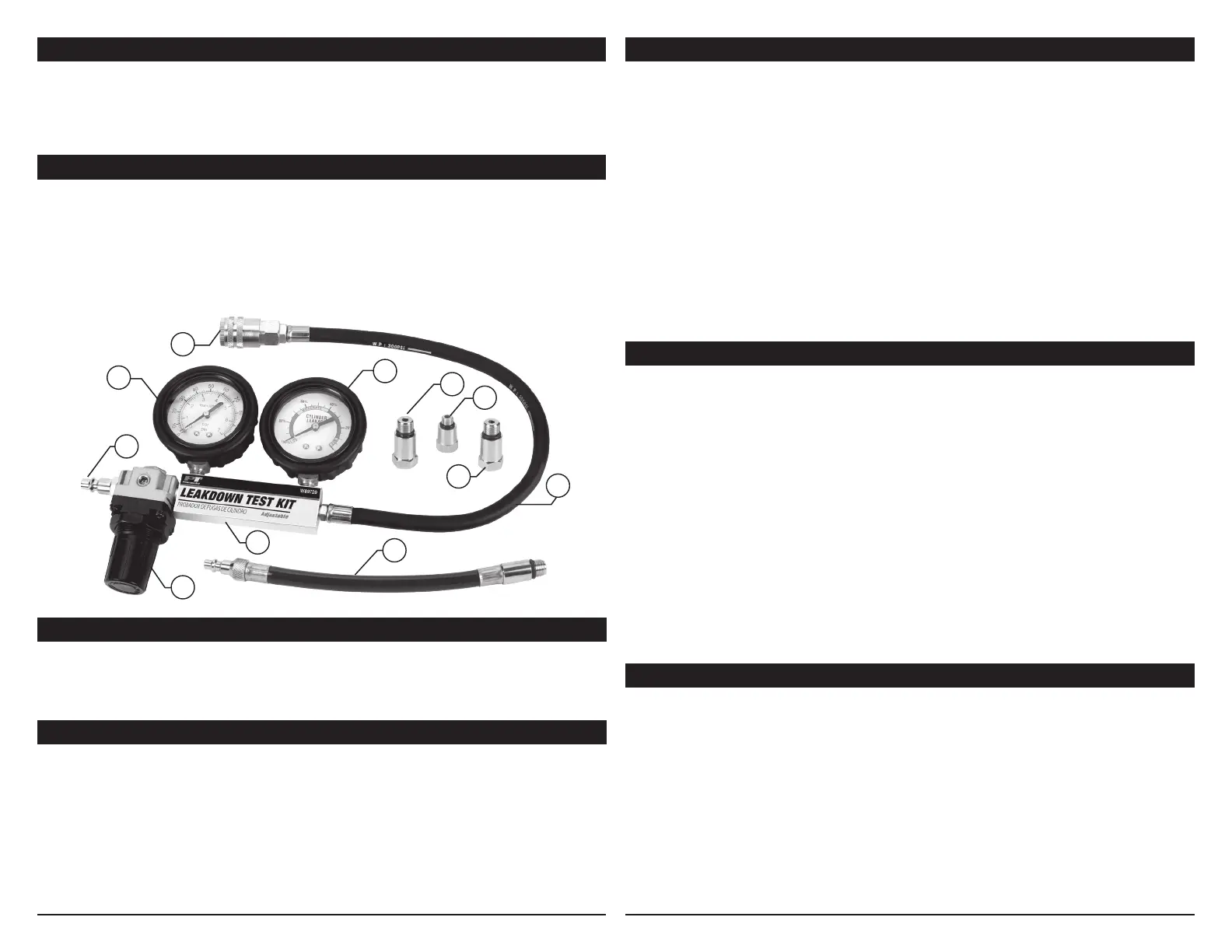

1. Pressure gauge

2. Leakage gauge

3. Metric adapter M12 x 1.25

4. Metric adapter M14 x 1.5

5. Metric adapter M10 x 1.5

6. Female quick connector

7. Male quick connector

8. Regulator

9. Gauge base

10. Adapter hose

11. Extension hose

• Properly mainained products are less likely to malfunction. Do not use damaged products. Tag damaged

products “Do not use” until repaired.

• Check for any condition that may negatively affect the Leakdown Test Kit’s operation. If readings are

inconsistent, or if it appears that the gauge is not functioning properly, the Test Kit should be serviced

by a qualied service technician. Many accidents are caused by poorly maintained products.

•

Use only accessories that are recommended by the manufacturer for your model. Accessories that may be

suitable for one product may become hazardous when used on another product.

• Industrial applications must follow OSHA requirements.

• Maintain labels and nameplates on the Leakdown Test Kit. These carry important information. If

unreadable or missing, contact Wilmar Corporation for a replacement.

• Use the right product for the job. There are certain applications for which this product was designed.

Do not use small products to do the work of larger industrial products. Do not use this product for a

purpose for which it was not intended.

• Product service must be performed only by qualied service technician. Service or maintenance

performed by unqualied personnel could result in a risk of injury.

• When servicing the Leakdown Test Kit, use only identical replacement parts.

A cylinder leakdown tester can give you valuable information about where an engine’s compression is being lost.

For example, a compression test on an engine shows a cylinder with low compression. Performing a leakdown test

will show where the loss of compression is, such as intake or exhaust valves, head gaskets, rings or pistons, or the

engine block itself. Here are some places to look when a high leakdown result is found:

1. Tailpipe for exhaust valve leaks

2. Carburetor or throttle body for intake valves

3. Oil ller or dipstick tube for rings and piston issues

4. Radiator for head gasket or cylinder block issues

Keep in mind that all engines will have some leak loss, no engine seals 100%. If there is low compression and the

gauge shows that the cylinder is 100% sealed, look for a blockage of the tool or low pressure setting. If the cylinder

is leaking very high or at 100% leak, check to see that the piston being tested is at TDC on the compression stroke,

otherwise an intake or exhaust valve will be open, causing a faulty reading.

Always refer to the vehicle’s factory repair manual for acceptable leakdown numbers.

IMPORTANT NOTE: Be sure the regulator knob is turned fully counter-clockwise before

connecting the cylinder leakage tester to a pressurized air source. Failure to do so may result in

damage to the tool.

NOTE: Engine must be at normal operating temperature for accurate testing. Start engine and let

it warm up to normal operating temperature, then turn it off for testing.

WARNING:

Always run engine in a well ventilated space. Running engines produce Carbon

Monoxide, a colorless, odorless gas that can cause personal injury or death. Keep hands and

loose objects away from running engines. Always wear approved eye protection.

OPERATING INSTRUCTIONS

ABOUT CYLINDER LEAK TESTING

GENERAL SAFETY RULES

TECHNICAL SPECIFICATIONS

IMPORTANT SAFETY INSTRUCTIONS

MPORTANT SAFETY INSTRUCTIONS,

GENERAL SAFETY RULES

1

6

3

4

5

2

7

10

9

11

8

TOOL FEATURES

2 3

Loading...

Loading...