PDI SOP

Dealer Development Center

12

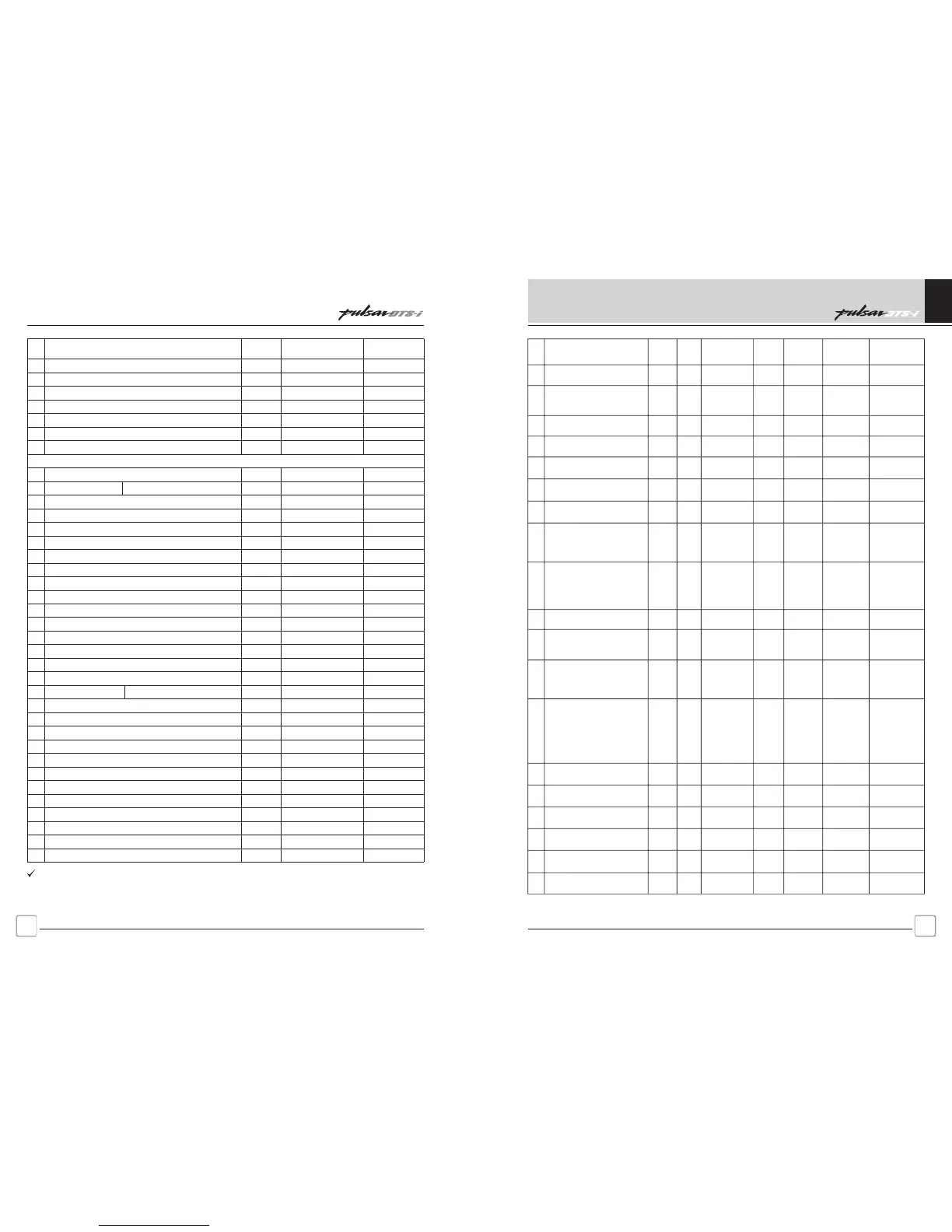

Pre Delivery Inspection Checklist

Dealer Development Center

11

Sl. Check

PDI done by BAL/

Service Engg.

PDI Done by

Dealer

Check Points for PDI

12

FLAT SPOT (GIVE CO %)

13

DRIVE CHAIN slack (mention amont of play)

14

BRAKE OPERATION - FRONT/REAR

FRONT BRAKE

REAR BRAKE EFFECTIVENESS

BRAKE LIGHT REMAINING ON CONTINUOUSLY.

15

GAP AT THE REED SWITCH AND MAGNETO.

CHECK POINTS FOR PDI

16

17

18

19

20

21

22

23

24

LOOSE PARTS

KICK BOSS BOLT

ENGINE MOUNTING BOLT

ENGINE NOISE

CHAIN TENSIONER / TIMING CHAIN

ENGINE OIL LEAKAGE

DRAIN BOLT

MAGNETO COVER

CRANKCASE JOINT

OIL FILLING PLUG

OHC COVER

TAPPET COVER

BENJO BOLT

CHAIN TENSIONER 'O' RING

OIL LEVEL INDICATOR WINDOW

OIL FILTER COVER

CLUTCH OPERATION

HARD

CLUTCH JUDDERING

PLATING DEFECTS

HANDLE BAR

ENGINE OPENING DURING PDI (If any)

(Give engine no & reason for engine opening)

FRAME OPENING DURING PDI (If any)

(Give chassis no & reason for chassis opening)

OTHER DEFECTS :

MINOR ADJUSTMENTS

TRANSIT DAMAGES (Send photographs)

TAPPET NOISE

Marked if the ok observed

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

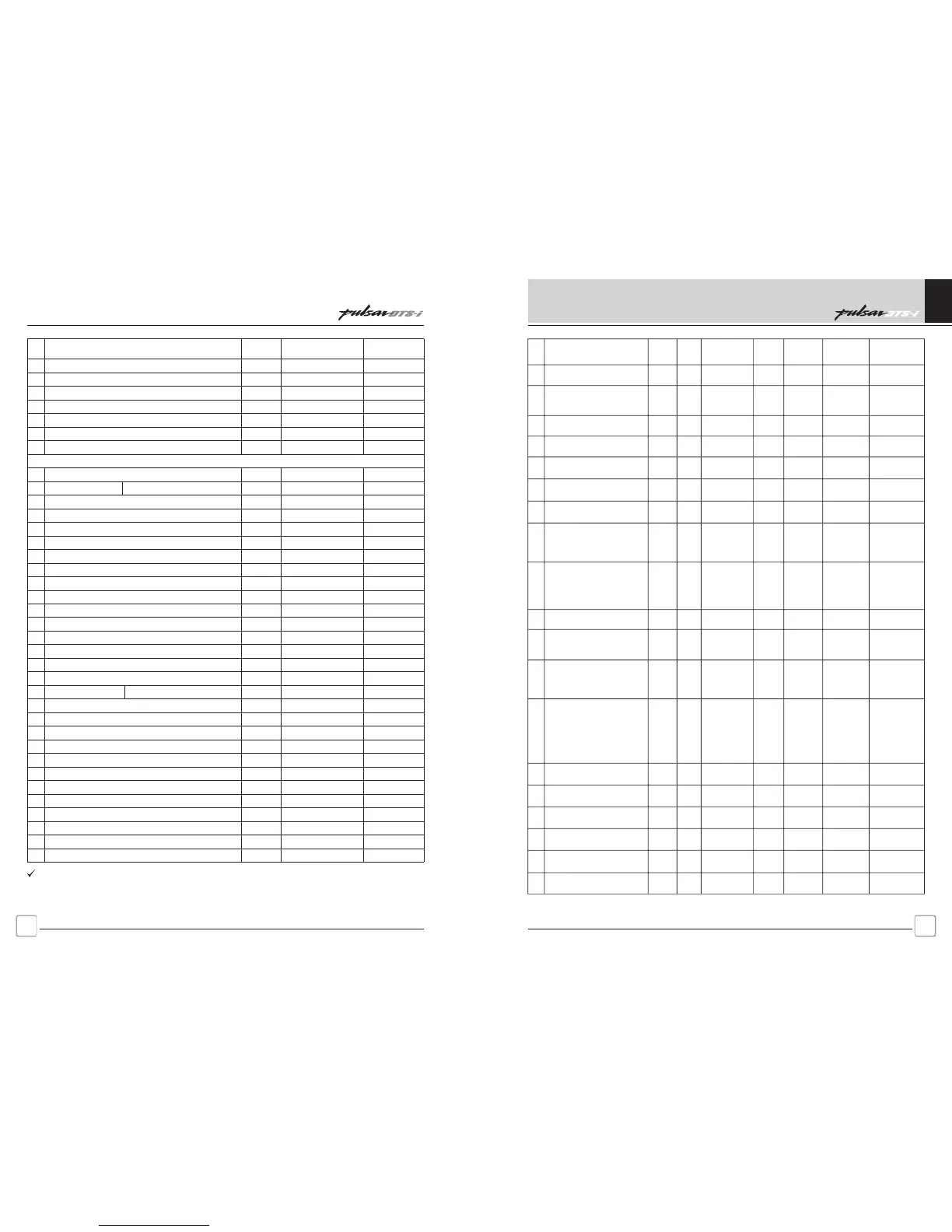

Description

Position

SMM GP Tools

Special

Tools

PNR & its

Attachment

Consumables

Sr.

No.

1

Identify & Park Vehicle on

Work Bay

0.80

2

Remove the Thermocol and

additional packing if any. Study

PDI card and Work content.

0.50

3

Open Petrol tank cap

& pour petrol

0.50

Petrol, Waste

Cloth

Measuring Jar,

Funnel

12-13 Ring

Spanner

Check for smooth operation of

fuel cock lever

Check and correct tyre inflation

pressure - Front Wheel

Check front brakes for efficient

working & Adjust if required.

Check clutch cable operation &

Adjust if required.

Check & top up engine oil level,

if required.

0.10

0.20

0.10

0.30

0.10

4

8

7

5

6

RH

RH

12-13 OE

Spanner

Front

/ RH

Pencil Type

Pressure Gauge

Front

9

Check Battery voltage, fill /

top-up electrolyte, apply

petroleum jelly, connect

terminals properly.

LH

0.60

Screw Driver,

Distilled water

Filler, 10mm

‘T’ Spanner

Cloth, Fine

Polish Paper,

Petroleum

Jelly,

Distilled Water

10

Inspect Rear Shock Absorber

setting & correct if necessary.

RH/LH

0.10

11

Check Rear brakes for efficient

working & adjust if required.

Rear

0.10

14-15 No.

O.E. Spanner

12

Check and Correct tyre inflation

pressure - Rear Wheel.

Rear

0.20

Pencil Type

Pressure Gauge

13

Lubricate chain and Check /

Adjust chain slackness if required.

LH

0.40

20-22, 24-27

Ring Spanner,

10-11 No. OE

Spanner,

Torque Wrench,

Socket Set,

Oil Can

Cloth,

SAE 90 Oil

14

Check Choke lever operation

LH

0.05

10-11 No.

OE Spanner

15

Check Accelerator cable free play

LH

0.05

8 & 10 No.

OE Spanner

10-11 No.

OE Spanner

16

Check & Adjust TPS

LH

0.10

17

Check gear shifter lever operation

LH

0.05

8 No.

‘T’ Spanner

18

Check & Adjust steering and

Handle bar for free movement.

RH /

Front

0.20

12-13, 16-17

Ring Spanner

M & T / Service

Shop Equipments

Lifter Bay

Air Gun

Analogous/Digital

type Pressure

gauge, Air filling

Valve

Hydrometer,

Battery Charger,

Battery Tester

Cloth,

Graphite Grease,

Fine Polish Paper

Analogous/Digital

Type Pressure

Gauge, Air Filling

Valve

Air gun

Fork Spanner

19

Check front mudguard alignment

wrt Front Wheel

Front

0.05

Loading...

Loading...