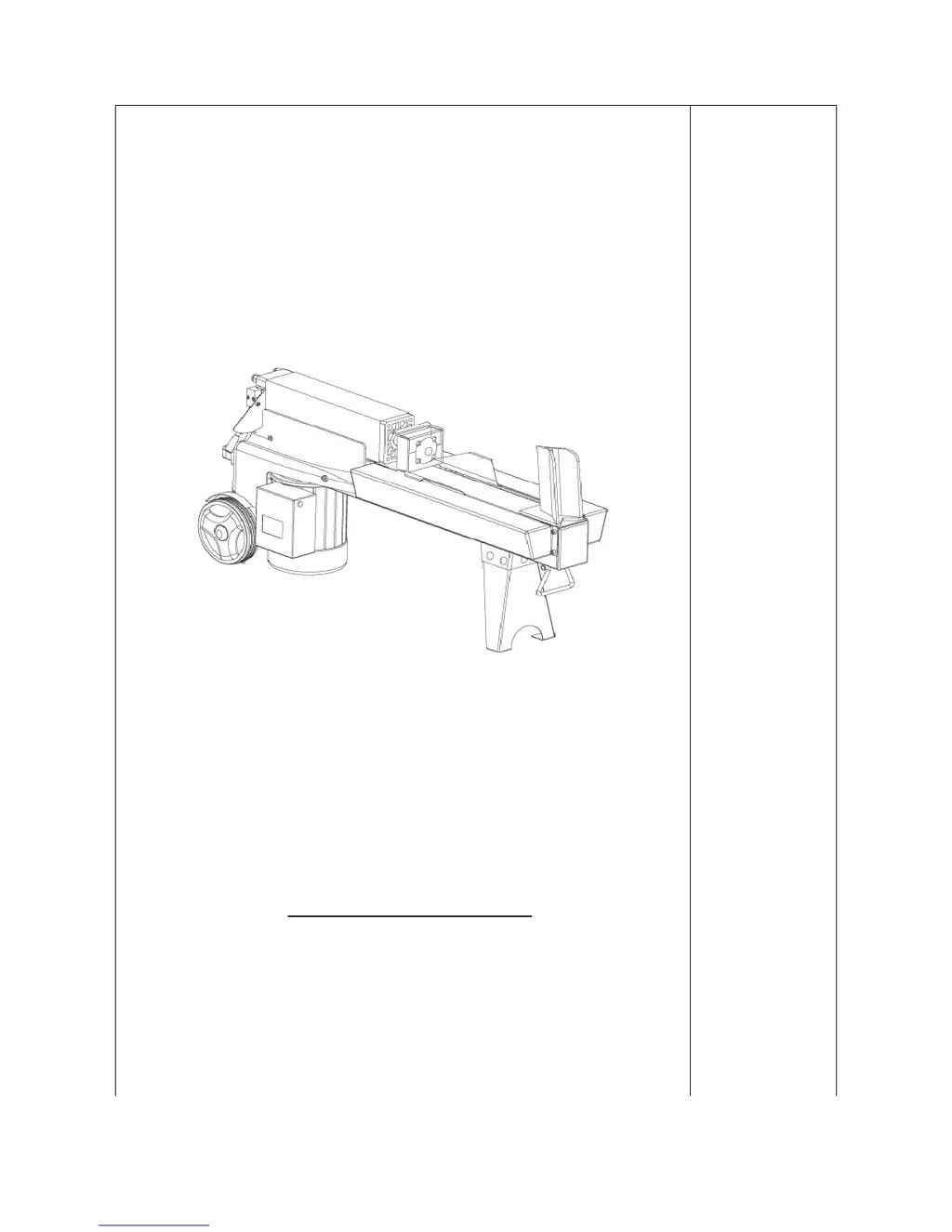

Why does my QCI Log Splitter fail to split logs?

- MMr. Benjamin MitchellAug 1, 2025

If your QCI Log Splitter fails to split logs, several factors could be at play. First, ensure the log is positioned correctly. If the log's size or hardness exceeds the machine's capacity, reduce the log size. Another potential issue is oil leaks, in which case you should locate the leak(s) and contact the dealer for assistance. Also, contact the dealer if an unauthorized adjustment was made on the Max. Pressure Limiting Screw. Lower max pressure rating was set.