obtained. Use micro only as specifically shown - never use micro

between glass layers.

....

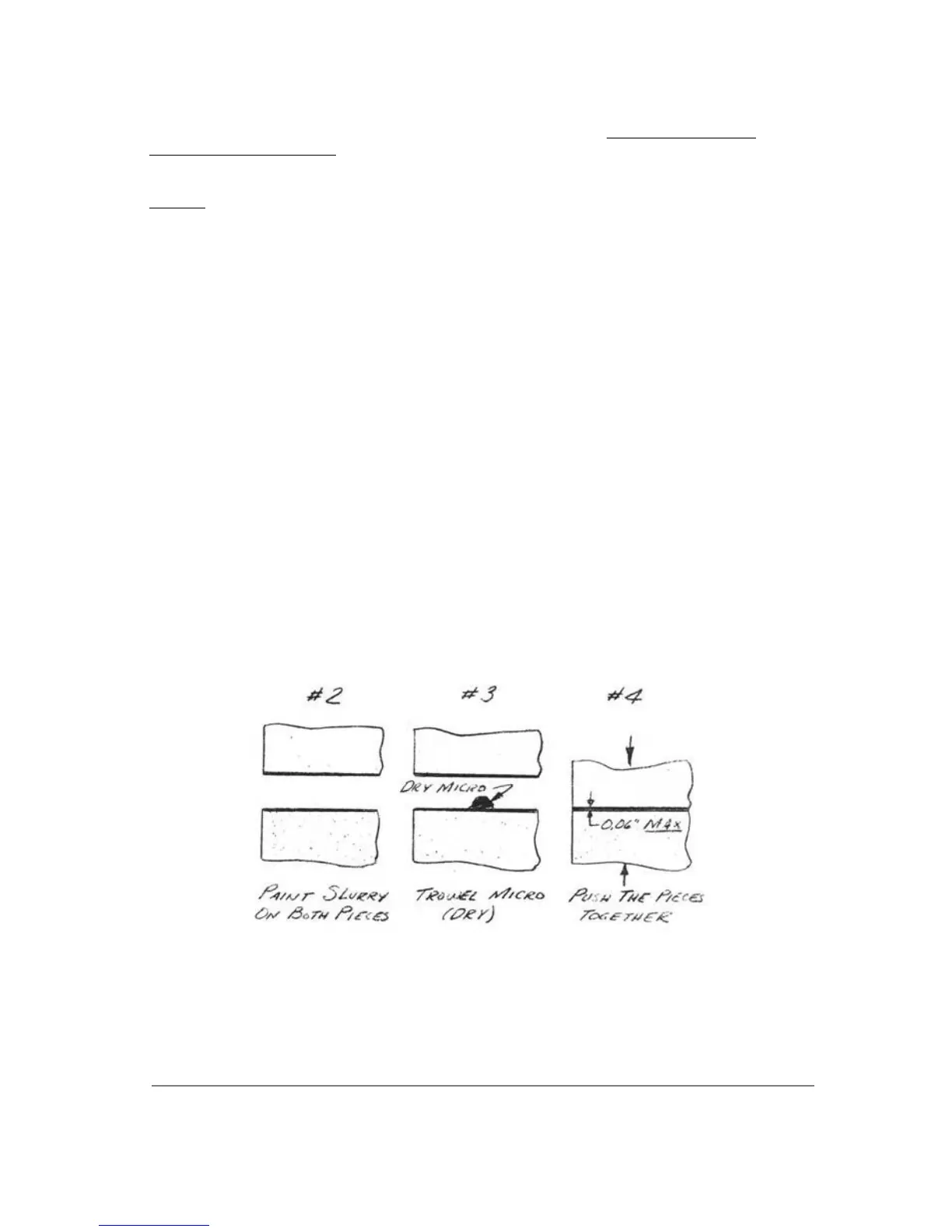

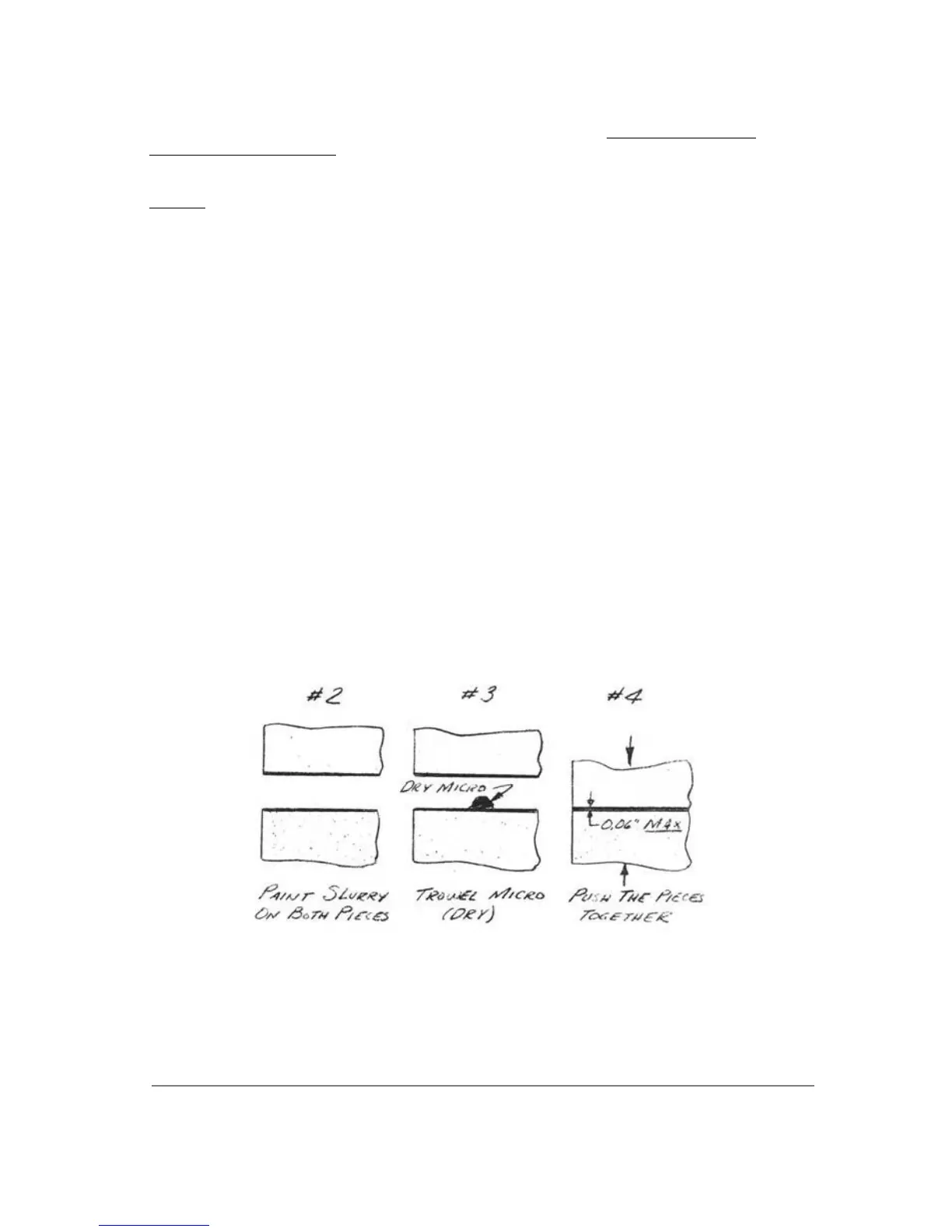

Always use the following method to join foam blocks. This is extremely

important.

1. Check that the foam blocks fit closely together.

If there are voids over 1/16 inch, sand to fit, or

fill the void with a sliver of foam.

2. Paint a light coat of micro slurry on both

surfaces. If joining foam to fiberglass, paint

pure mixed epoxy (no microspheres) on the

fiberglass surface and micro slurry on the foam

surface.

3. Refer to the sketch and trowel wet or dry micro in

the center of the joint. Thus when joined the

micro is pushed outward expelling (rather than

trapping) air. If the fit is excellent use dry

micro.

4. Push the two pieces together, wiggling each to

move the micro toward the surfaces. Be sure the

micro is no thicker than 0.1 inch at any place, to

avoid exotherm. Wipe off any excess. Do not be

concerned if the micro does not completely reach

the surface. That void can be filled immediately

before skinning the part.

PAGE 3-4

Loading...

Loading...