Quincy Compressor

1312100602, September 2012 11 3501 Wisman Lane, Quincy IL - 62305-3116

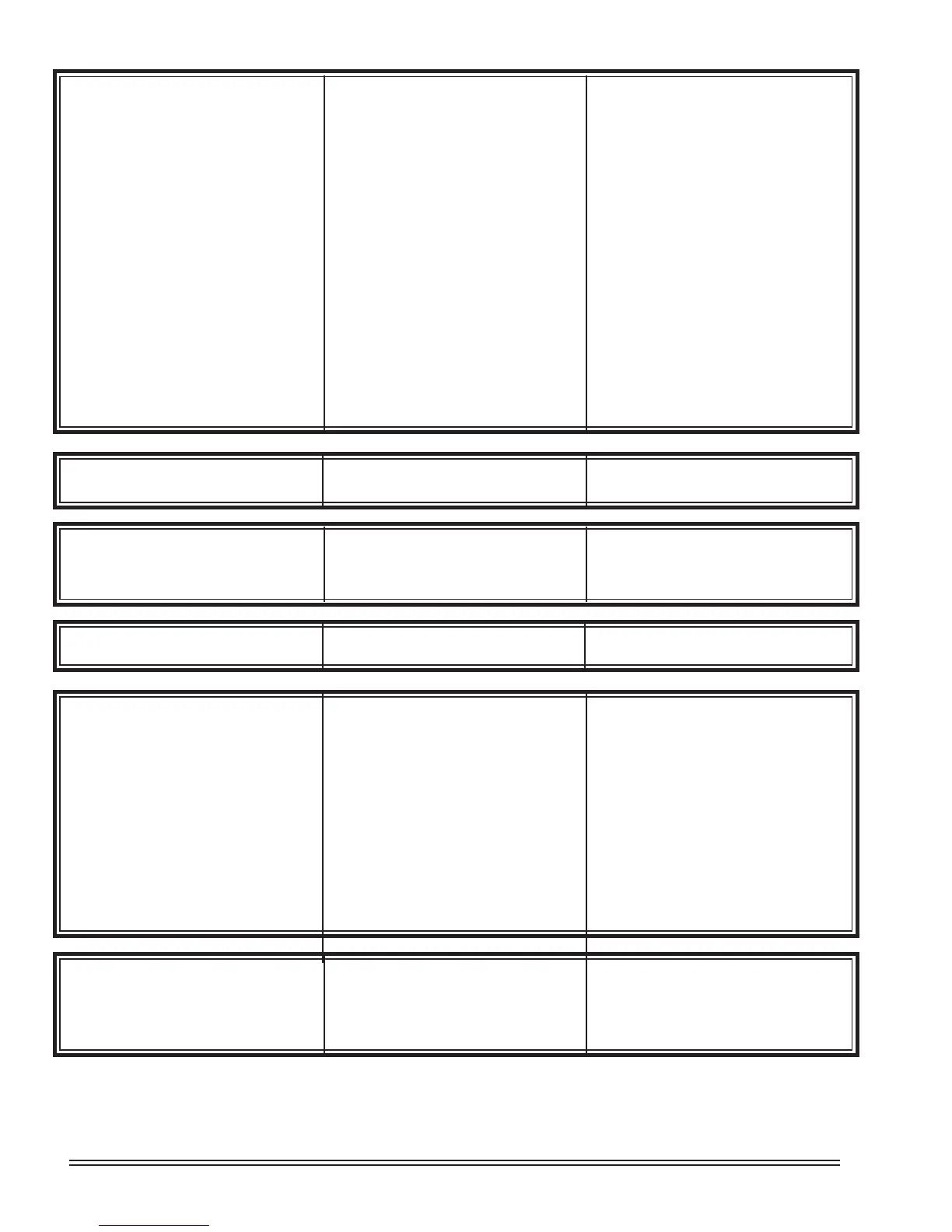

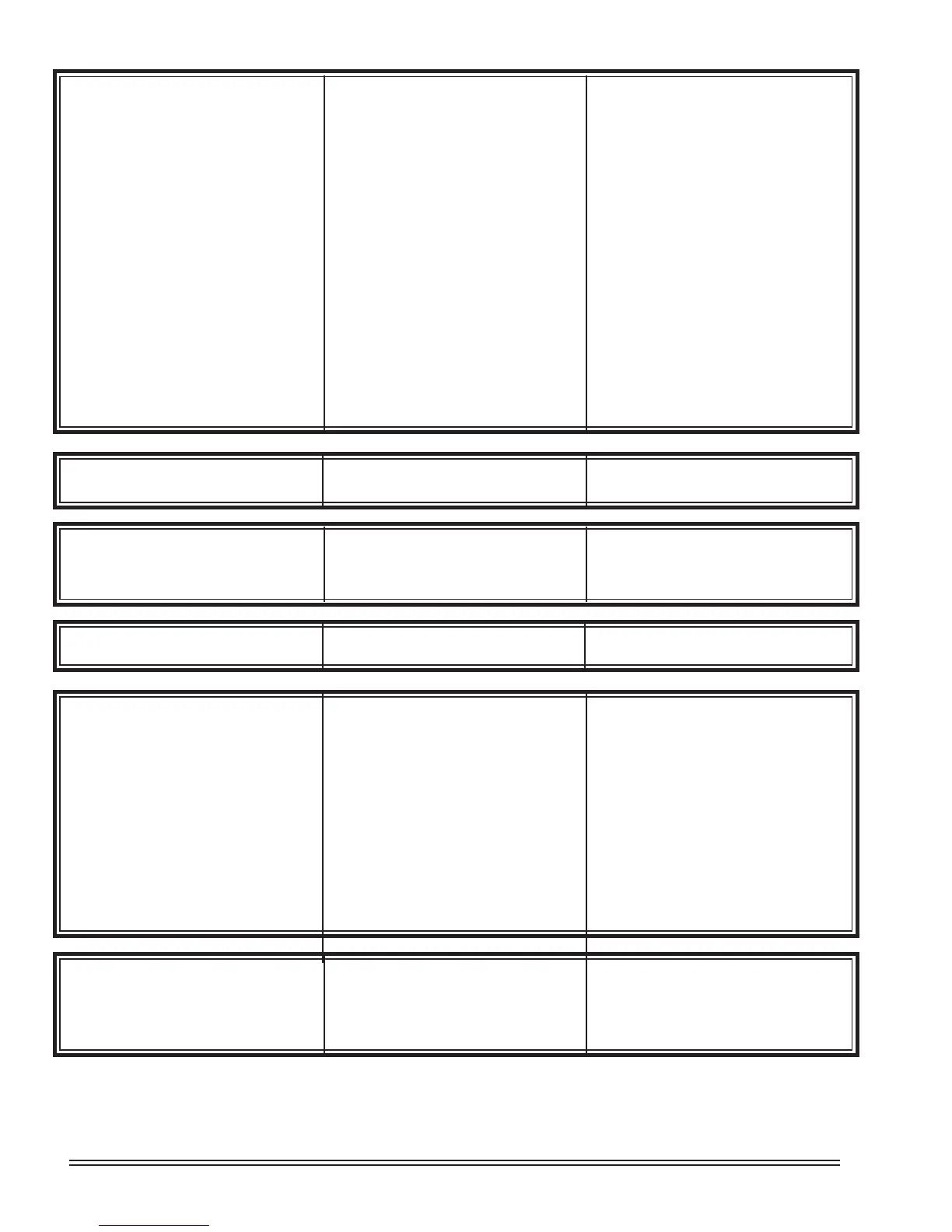

1. Turn unit o, unplug it, &

tighten or replace ttings or

components.

2. Replace faulty check valve.

1. Loose connection or leak (pipe,

tank drain valve, tubing, t-

ting or hose).

2. Faulty check valve.

12. Tank loses pressure rapidly

when compressor shuts o.

1. Check for leaks or restrictions

in hose or piping. Repair.

2. Clean or replace lter.

3. Tighten belt (refer to Belt

Align ment & Adjustment).

4. Replace with larger hose or

connec tors.

5. Either use a smaller tool or a

larger compressor.

6. Turn the regulator to the

proper set ting / replace faulty

regulator.

1. Leaks or restrictions.

2. Restricted air intake (lter

plugged).

3. Slipping belt.

4. Hose or hose connectors too

small.

5. Compressor incorrectly sized.

6. Regulator not turned up to

high enough pressure / faulty

regulator.

11. Insucient pressure at tool or

acces sory.

1. Contact qualied electrician.1. Reversed wiring polarity.10. Compressor runs backwards.

1. Change lubricant. Move

compressor or air inlet to less

humid atmosphere.

1. Water in lubricant due to

humidity or condensation.

9. Crankcase lubricant is milky.

1. Take to Authorized Service

Center.

1. Damaged inlet (reed) valve.8. Air blowing from inlet lter.

1. Drain lubricant. Rell to

proper level with proper lubri-

cant (refer to Lubrication).

2. Tighten bolts on compressor

to proper torque or replace

gaskets.

3. Take to Authorized Service

Center.

4. Drain lubricant & rell with

proper lubricant (refer to Lu-

brication).

5. Level compressor.

6. Take to Authorized Service

Center.

7. Clean or replace crankcase

breather.

1. Crankcase overlled with

lubricant.

2. Lubricant leaks.

3. Worn piston rings.

4. Wrong lubricant viscosity.

5. Compressor on unlevel sur-

face.

6. Scored cylinder.

7. Plugged crankcase breather.

7. Excessive lubricant consump-

tion and/or ex cessive lubricant

in hose.

PROBLEM CAUSES CORRECTION

Loading...

Loading...