P.C.B. SM 20015 – boiler settings

9

D

10

20

30

40

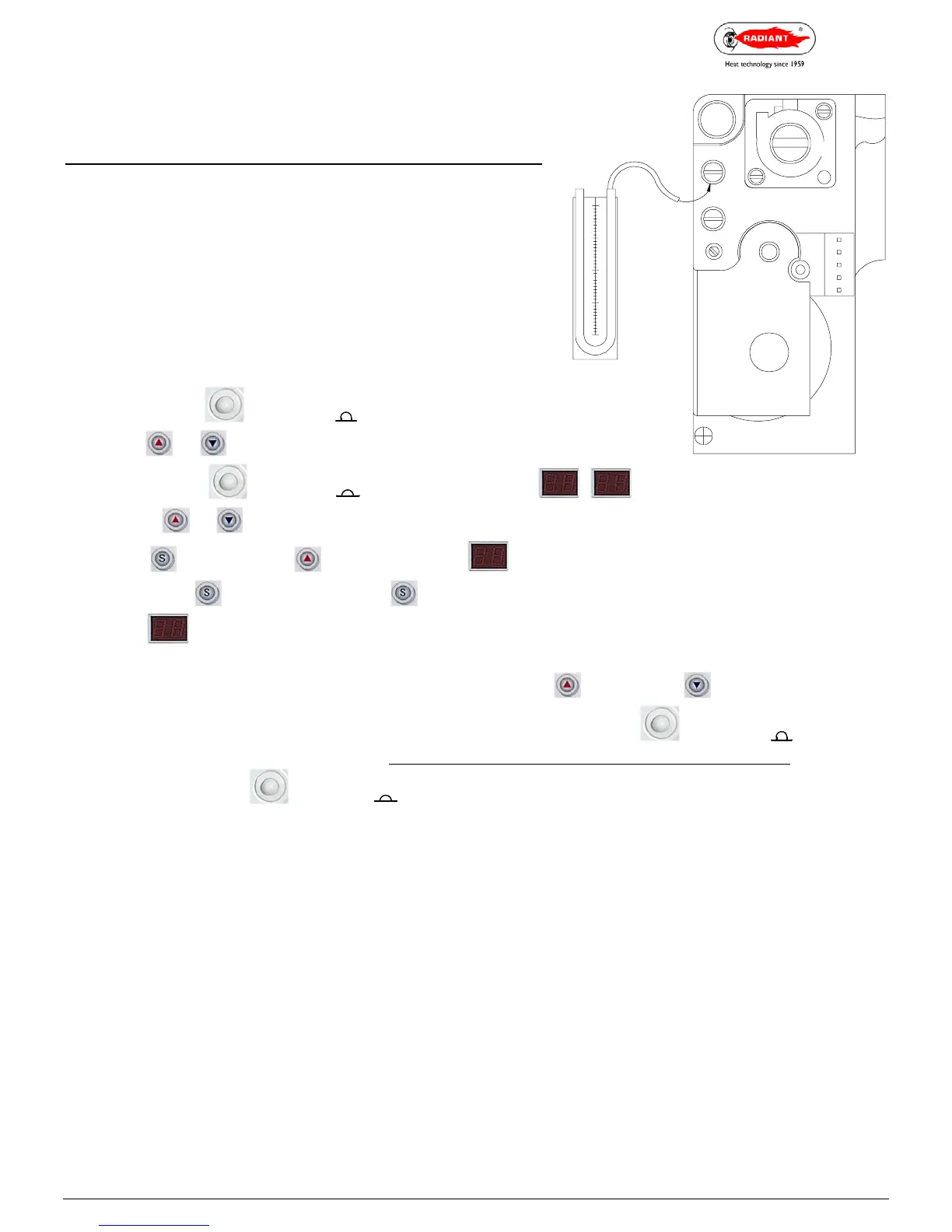

MANO METRO

9: Mechanical minimum gas pressure setting

The mechanical minimum gas pressure is factory calibrated on all boilers at 17/18 mmH20.

When replacing the gas valve adjust the mechanical minimum pressure as follows:

:

• Using a single cut screwdriver turn D screw (fig.1 ) clockwise and tight it ;

• To adjust the mechanical minimum, turn D screw (fig.1) counter-clockwise for

two complete turns.

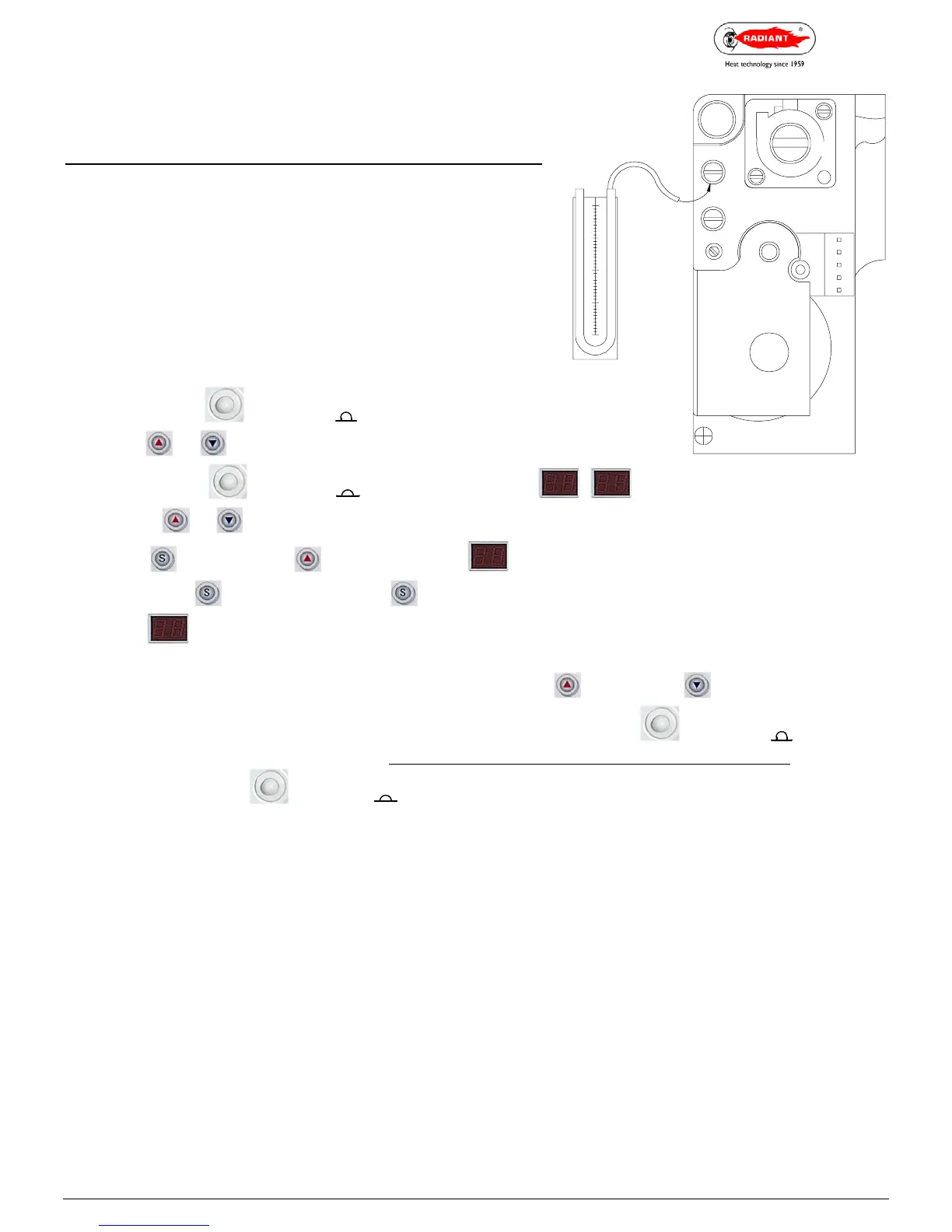

Parameter 10 setting: MINIMUM HEATING OUTPUT SETTING

To check or modify the existing pressure value:

a. insert a manometer into the gas valve pressure point B (fig.1);

b. Put ON / OFF button

1 in OFF position ( );

c. Push pad

6 and simultaneously and keep them pressed;

d. Put ON / OFF button

1 in ON position ( ) and wait until the display shows - ;

e. Release pad

6 and ;

f. Keeping pad

pressed, press pad 6 and select parameter no. ;

g. Release service pad

, press and release service pad ;

h. The display

will show the parameter value to be set or modified;

i. The manometer inserted in the pressure point B (fig. 1) will show the minimum gas pressure;

j. If that value is different than the one stated on the data plate, modify it by pressing pad

6 to increase or pad to decrease gas pressure ;

k. Once the minimum gas pressure has been adjusted, switch the boiler OFF by putting ON / OFF button

1 in OFF position ( );

l. Remove the silicon pipe from the pressure point B (fig.1), close tightly the pressure point screw and make sure there are no gas leaks;

m. Position the ON / OFF button

1 in ON position ( );

Gas valve VK 4105G

P

Loading...

Loading...