14 www.raider.bg

■ Check that the distance between the

electrodes of the spark plug is 0.6-0.7 mm.

■ Pull the rope starter 2-3 times to make sure

that the engine is in good condition.

♦ Fueling

■ Refueling should be done when engine

inoperative.

■ gasoline must be unleaded N95, oil should

be a two-stroke gasoline engine. The ratio of fuel

mixture between gasoline and oil is 25-30:1. Poor

quality gasoline will aect engine performance

and will destroy it. While make up fuel tank

strainer must be in place to prevent penetration

of dirt in the tank.

♦ Load (chemical solution)

■ When spraying: While adding a solution, the

tap should be closed, see Figure 8.

■ In aerial spraying:

g.8

,

The

handle of the valve hole of dust must be in

lowest position, otherwise the machine will throw

chemicals.

Chemical dust can easily turn into a lump,

so the chemical tank should be kept chemicals

for a long time. While spraying the chemical tank

lid should be tightened well. After loading the

powder, please clear the thread of the neck of the

chemical tank, then tighten well.

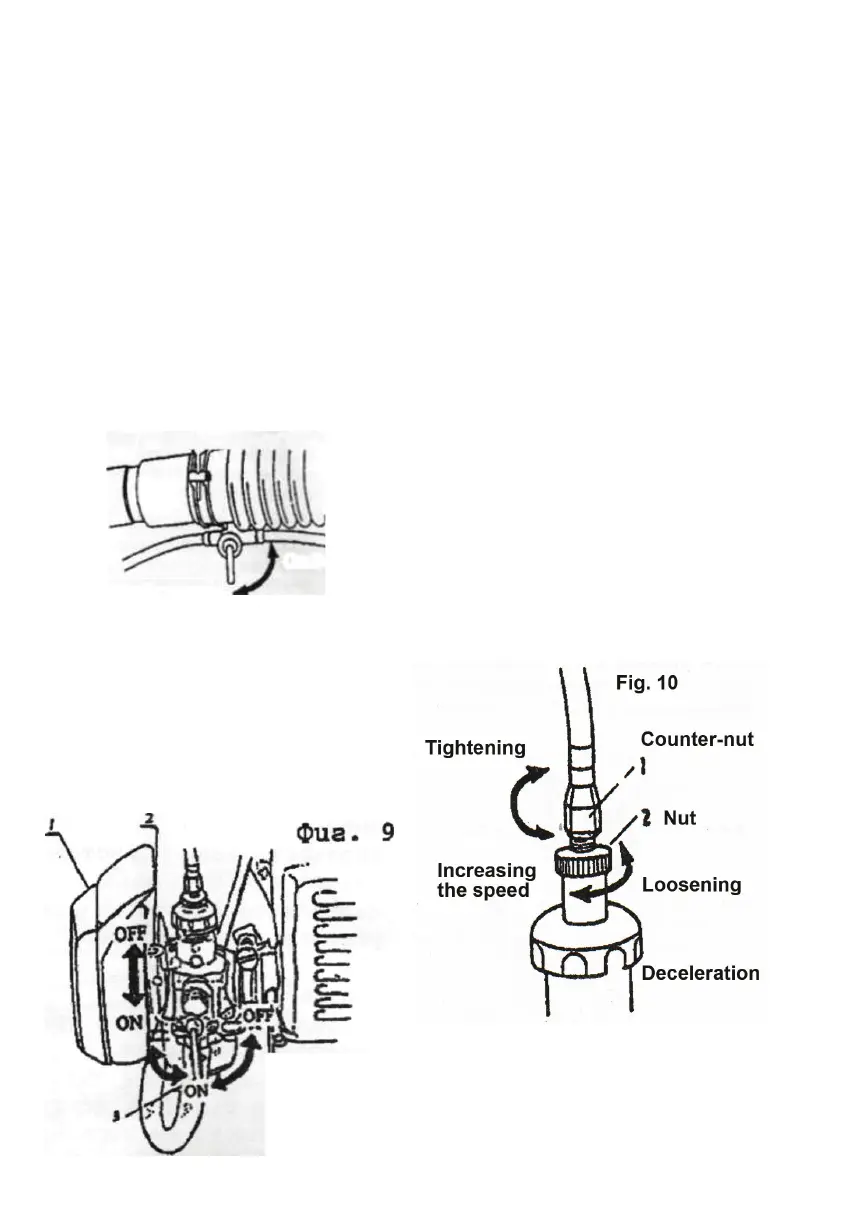

♦ Starting a cold engine:

1. Air lter

2. Choke

3. Fuel valve

■ Open the fuel cock, see Fig. 9

■ Place the handle of the gas at the starting

point.

■ Place the choke end position “OFF” (closed).

First eece gap by slow withdrawal of the rope

until you feel resistance

■ Pull, if necessary, the starter rope several

times and return it slowly. Do not leave the handle

to return freely

to avoid damaging the starter.

■ After starting the engine, open the choke

fully position “ON”.

■ Allow the engine to operate at low speed for

2-3 minutes, then begin to spray or dust.

♦ Starting a warm engine

■ Leave the choke fully open,

position “ON”.

■ If the engine is choked: Let o the throttle

closed and pull the starter rope several times.

Then start the engine as described above.

■ Setting the operating speed.

Turnover does not correspond to the current

position of the throttle lever in working order or

the engine may stop when the lever is lowest -

position. Adjust as follows. See Fig.10 ■ Loosen

counter nut of the cable.

■ Turn the adjustment nut on the right to

reduce speed and back to zoom.

■ Once setup is complete,

Tighten counter nut again.

♦ Stop the engine

Deceleration

■ During the rst spray solution to close the

Loading...

Loading...