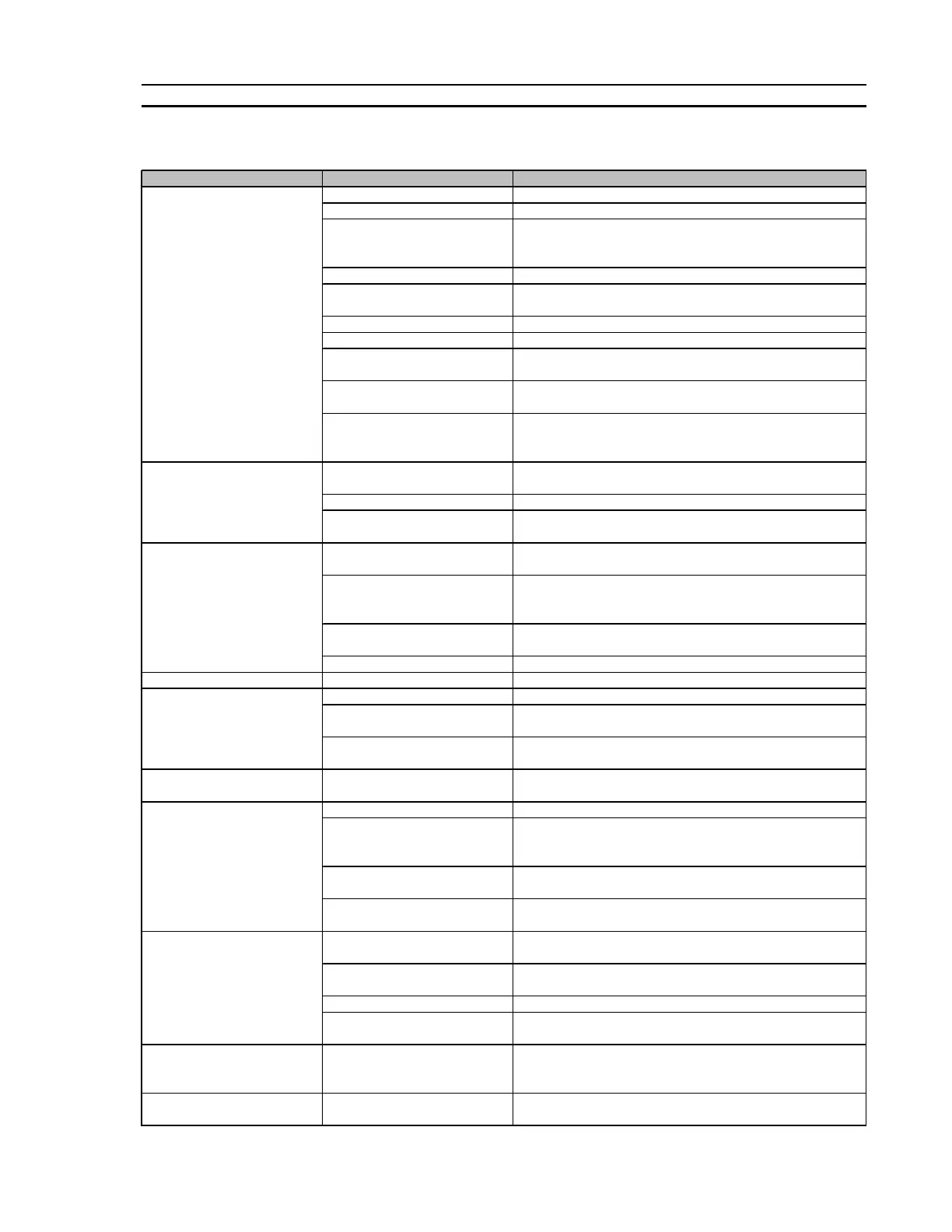

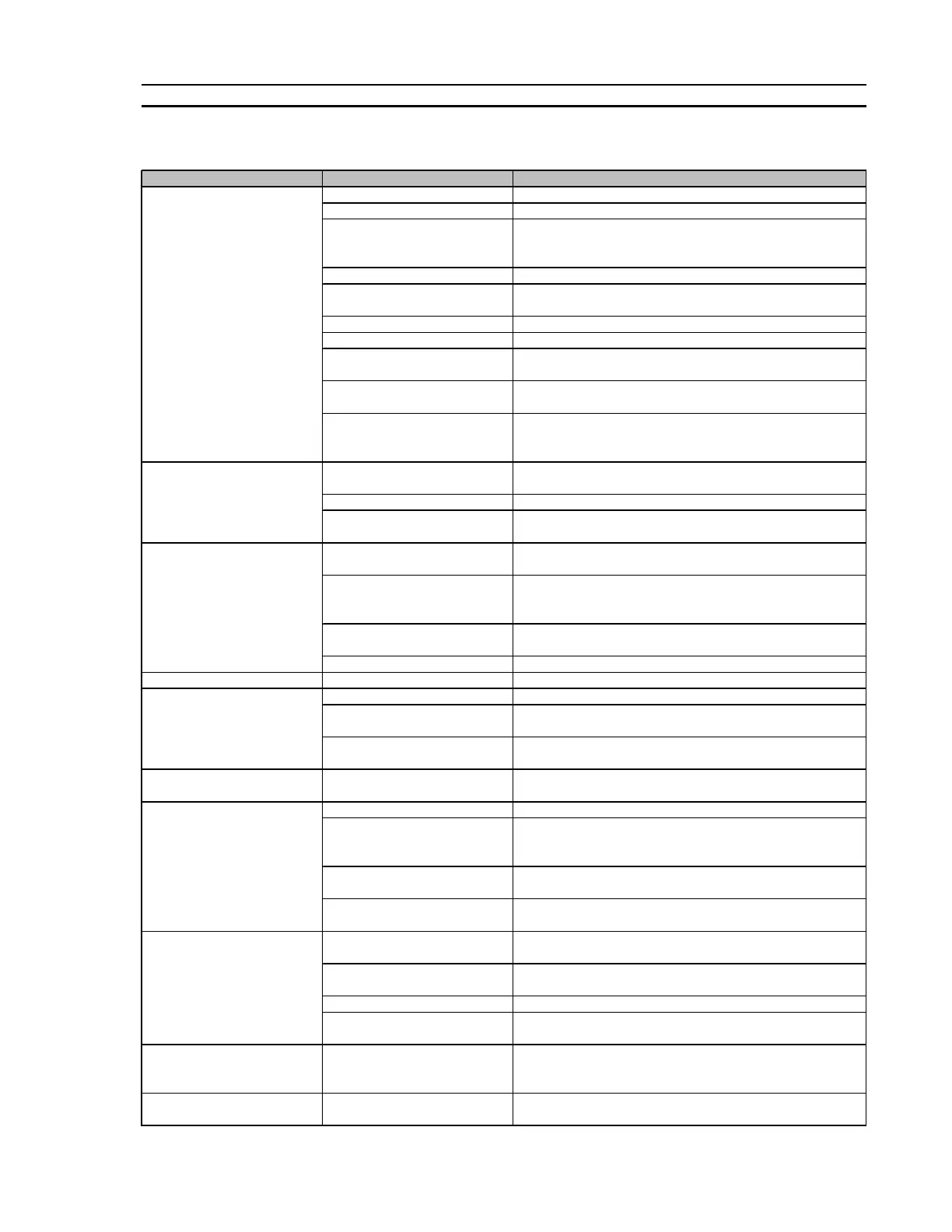

OIM‐600056 Rev.0 20

Thissectionprovidesbasictroubleshootinginformation.Determinationofspecifi ccausestoproblemsarebestidentifiedbythoroughinspectionsperformedbypersonnel

instructedinsafety,operationandmaintenanceofthisequipment.Thechartbelow providesabriefguidetocommonwinchsymptoms,probablecausesandremedies.

SYMPTOM CAUSE REMEDY

Insufficientornoairsupplyto

winch. Checkairsupplylineconnectionsandhoses.

Winchisoverloaded. Reduceloadtowithinratedcapacity.

Shippingplugsmaystillbe inplace. Removeshippingplugsinval ve andmotorexhaustports.

Emergencystopvalveengaged. Resetemergencystopvalve .

Motormaybedamaged . Disassembleandcleanthemotorandreplaceanybrokenordamagedparts.

Winch

isoverloaded. Reduceloadtowithinratedcapacity.

Winchisoverloaded. Reduceloadtowithinratedcapacity.

Oilleakfrommotorendofwin ch. Reductionassemblyisleaking. Disassembl ewinchandinspectreductionassemblyseals.

Motormaybedamaged . Disassembleandcleanthemotorandreplaceanybrokenordamagedparts.

Lowoillevel.

Checkoil levelin

motor.Addoilasrequiredtoobtainproperlevel.

Brake(s)notreleasing. Refertobrakesin"MAINTENANCE"sectiononpage2.

Pressurizediscbrakereleaseportandcheckforleakage.Replacebrakepistonseals

ifleakageisfound.Ensureairpressureatinlettodiscbrakeisatleast45 psig(3.1

bar/310

kPa).Inspectbrakepistonseal sandreplaceifsealsappeartobeleaking.

Disengagemanualdrumbrake,orreferto'AutomaticBandBrakeAdjustment'on

page2.

Checkhoseandfittingconnections.Inspecthose(s)forbreaks.Tightenfittingsand

repairorreplacehosesasnecessary.

Reduceloadtowithinratedcapacityof

winch.Ifoverloaddevicecannotbereset,

contactfactory.

Installordrainairsystemmoisturetraps,moisturecollectingairreceiversand

compressoraftercoolers.Aftercorrectiveactionhasbeentaken,disconnectlinesat

winchinletandpurgewithclean,dryairornitrogen.

Winchwillnotoperate

Overloaddeviceengaged.

Airleak.

Drumbrake

doesnotrelease.

Discbrakedoesnotrelease.

Ensureairpressureatwinchinletisatleast90psig(6.3bar/ 630kPa)atrated

volume . Cleanairlinefilter.

Throttleorpendantlevermovesbut

winchdoesnotoperate.

Check'AutomaticBandBrakeAdjustment'onpage2andbrakebandliningwear.

Checkbrakefricti ondiscwear.

Checkpendant/throttle leversspringreturntonormal(neutral)positionwhen

released.

Loadcontinuestomovewhenwinchis

stopped.

Winchmotorcontrolssticking.

Brakeisslippi ng.

Removeanddisassemblemotorasdescribedinthe"MAINTENANCE"sectionon

page2.Examineallpartsandreplaceanythatareworn

ordamaged.

Verifyairsupplypressureandvolumeatwinchinletmeetstherequirementslisted

inthe"SPECIFICATIONS"sectioninProductInformationManualFormMHD56278.

Cleanairlinefilter.

Checkbrakereleasepilotholeisnotrestricted.Checkseal soncylinderpistonare

notdamaged.Brakeshouldbereleasedat45psig

(3.1bar/310kPa).

Winchdoesnotliftloadordoesnotlift

ratecapacity.

Winchdoesnotlift/pullload.

Damagedorbroke npistonorconnecting

rod.

Disassembl eandrepairmotor.

Waterinoil.

Disassembl eandrepairmotor.

Improperlubrication.

Checkhoseandfittingconnections.Inspecthose(s)forbreaks.Tightenfittingsand

repairorreplace

hosesasnecessary.

Motordoesnotrunsmoothlyormakes

ex cessi venoiseduri ngoperation.

Damagedorbroke npistonorconnecting

rod.

Replaceoilwithtype recommendedin"LUBRICATION"sectioninProduct

InformationManual.Setlubricatortoprovide6to9dropsofoilperminuteat

maximumwinchoperatingcapacity.

Drainandrefill

withrecommendedoil.Operatewinchwithnoloadsl owly,inboth

directions .Ifnoisestill existsormotoroverheatsdisassembleandrepairmotor.

Reversevalve stickinginbushing.

Waterinairsupply.

Insufficientairsupply.

Motormaybedamaged.

Improperhoseorfittingsizes.

Motorrunshotormakesexcessivenoise

duringoperation.

Winch

runsslow.

Airlinesfreeze.

Throttleleverhardtoactuate,orlever

doesnotspringreturntoneutral.

TROUBLESHOOTING

Airleak.

Insufficientairsupply.

Brakeisnotreleasing.

Insufficientairsupply.

Motormaybedamaged.

Airlinesfrozenduetowaterinairsupply.

Checkfittings,connectionsandhosesforcorrectsizeandlength.Replacepartsthat

maycauserestrictairflow.Inspectairlinefilter.

Removeanddisassemblemotorasdescribedin

the"MAINTENANCE"section on

page2.Inspe ctallpartsandreplaceallwornordamagedparts.

Verifyairsupplypressureandvolumeatwinchinletmeetstherequirements.Refer

to"SPECIFICATIONS"sectioninProductInformationManual .Cleanairlinefilter.

Installordrainairsystemmoisturetraps,moisturecollectingairreceiversand

compressoraftercoolers.Aftercorrectiveactionhasbeentaken,disconnectlinesat

winchinletandpurgewithclean,dryairornitrogen.

Removeanddisassemblecontrolvalve.Cleancontrolvalvepartsandcheck

clearancebetwee nreversevalveandbushing.

Loading...

Loading...