HAS

6.2. WORKING DIRECTIVES

Compared with bending

around a circular rail,

bending work using an

angle rail

presupposes

a

number of different

compromises. As

there is not suitable bracing within

the bending radius,

which

would

support the radius,

a certain amount of distortion

is always

produced

in

a certain area of

the

radius.

At the same time, if the

bending cheek is closely

adjusted, the

point

of

application of force on the

bending

rail moves towards the

point

of rotation. The resull is

the leading leg effect.

Angle

rails are used frequently in

spite of this. The disadvantages

-

such as differences

in angle

and radius

-

are often more than compensated

for by the costs of setting up and

tools which would

be necessary

for a large number of

ditferent circular rails.

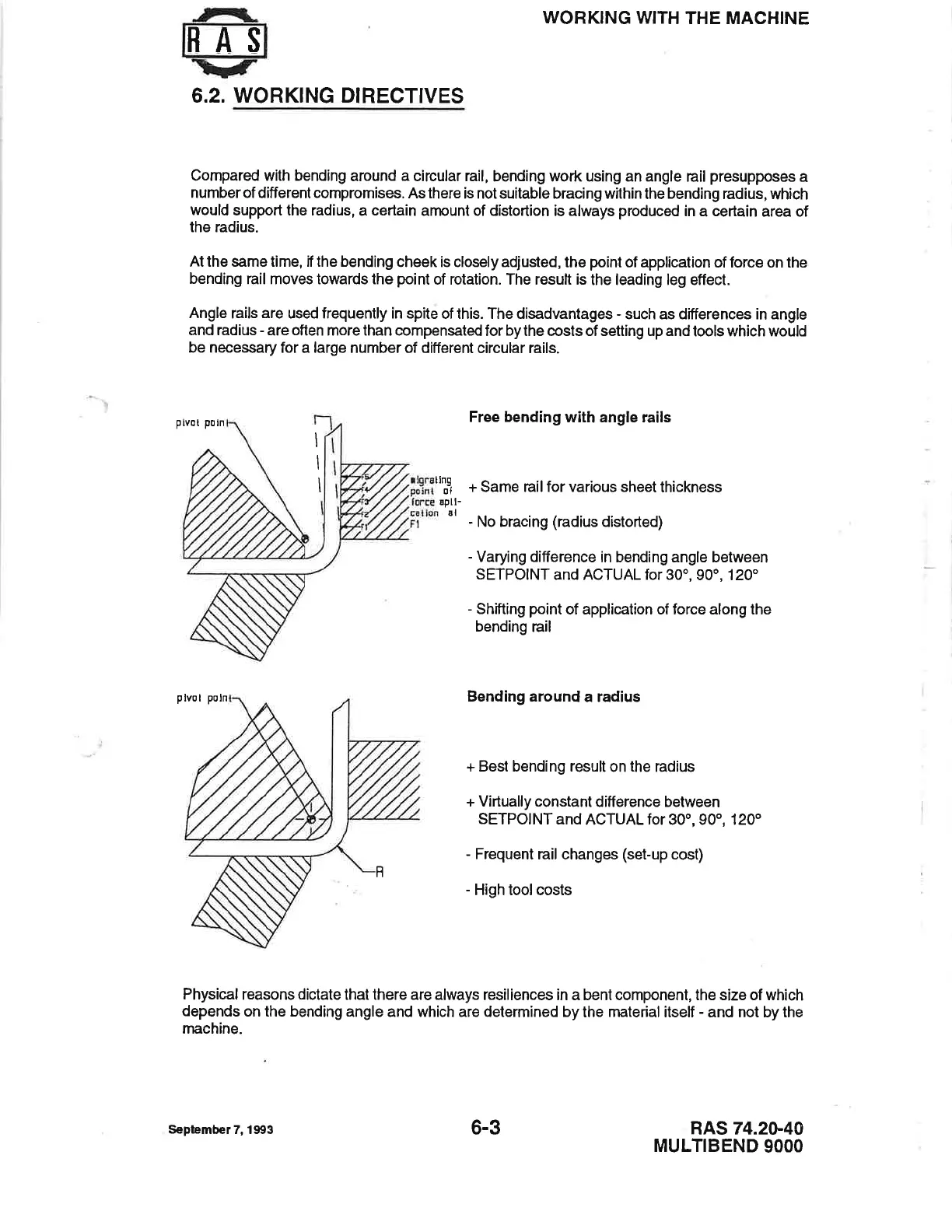

pivot poin

Free bending with angle rails

"Xs,

+ Same r:ail for various sheet

thickness

apll-

al

-

No bracing

(radius

distorted)

-

Varying difference

in bending angle between

SETPOINT

and

ACTUAL

for 30o,

90o, 120"

-

Shifting

point

of application of force along the

bending rail

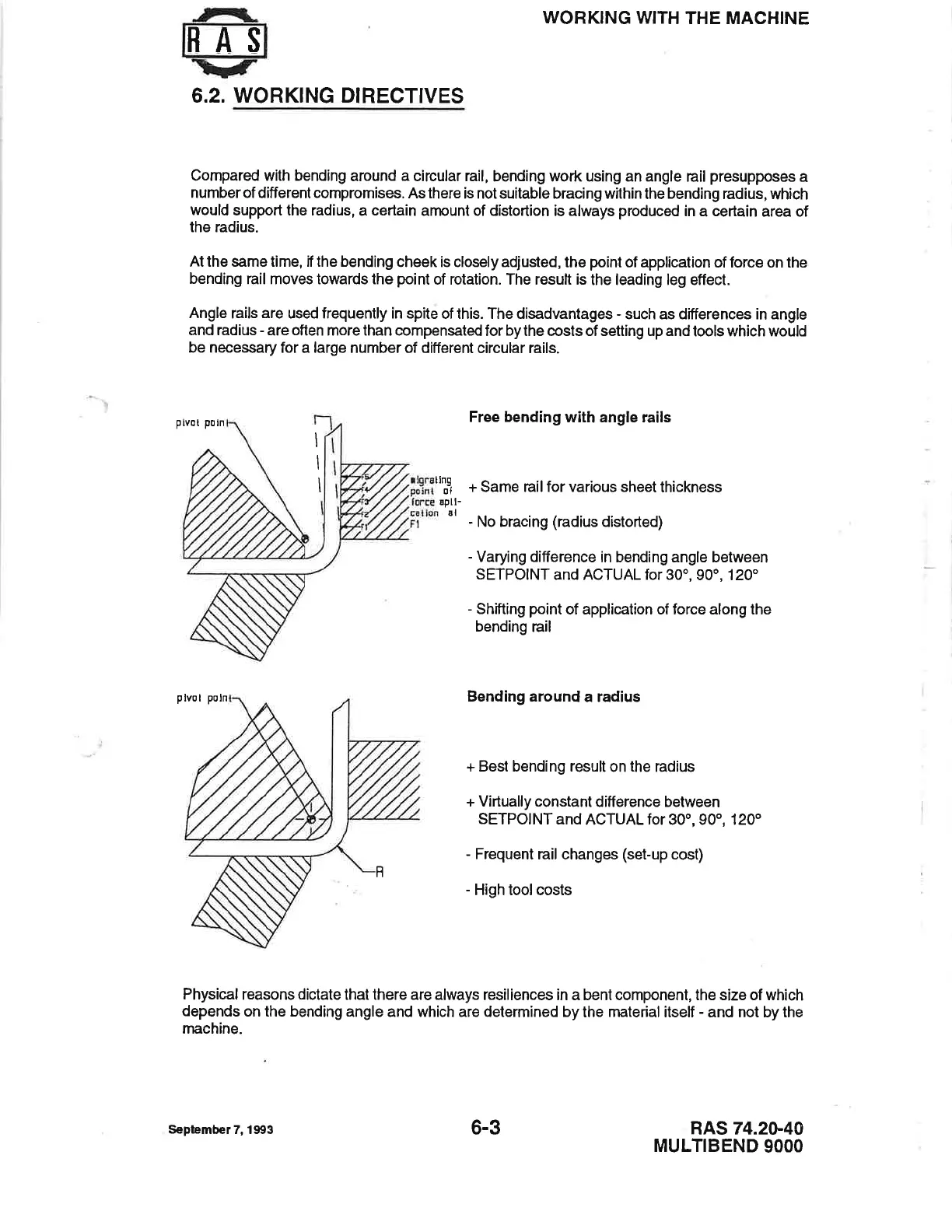

pivol poln

Bending around

a radius

+ Best bending

result on the radius

+ Virtually

constant difference between

SETPOINT

and

ACTUAL for 30o, 90o, 120o

-

Frequent

rail changes

(set-up

cost)

-

High tool costs

Physical reasons dictate that there are

always resiliences in a bent component,

the

size

of

which

depends on the

bending angle and which are determined by

the

material

itself

-

and not by the

machine.

RAS 74.20-40

MULTIBEND

9OOO

WORKING WITH

THE MACHINE

I

I

I

H

Sepbmber 7, 1993

6-3

Loading...

Loading...