CHAPTER 3

12 Hawkeye Nozzle Control Operation Manual

1. Verify the total number of Nozzle Control Valves (NCV’s) on the Hawkeye system matches the NCV’s detected

by the Hawkeye ECU.

NOTE: If the total number of nozzles displayed does not match the expected number of nozzle control

valves connected to the system, refer to Chapter 8, Troubleshooting, for assistance with the Hawkeye

nozzle control valve circuit.

2. The Hawkeye ECU will attempt to detect the number of nozzle control valves connected to the left boom

(center of the boom to the tip of the left boom) circuit. Check the displayed value against the actual number of

valves connected to the left boom circuit. If necessary, select the Nozzle Count field and enter the appropriate

number of nozzle control valves connected to the left boom circuit.

NOTE: To bypass nozzle configuration and operate the system without the Hawkeye Nozzle Control Valves,

press the Skip Nozzle Setup button. If the Nozzle Control Valves are installed on the machine, the

NCV’s will remain closed and must be manually bypassed at the boom by opening a secondary flow

outlet, or removed from the machine to apply product. The system will then operate as a

conventional sprayer with the Hawkeye ECU.

3. Select the applicator type:

• Sprayer - If full rate is required across the entire boom (sprayer or strip-tiller)

• Applicator - If 0.5X or 1.5X rate is required at the ends of the boom (28% applicator with 15 or 17

coulters)

4. Select the Next button to continue to the Nozzle Spacing prompt.

5. Select the Nozzle Spacing field and enter the distance between nozzle control valves. For liquid fertilizer

applicators, enter the crop row spacing.

6. Select the Next button to continue to the Tip Size prompt.

7. Select the Tip Size field and use the available options to select the orifice size of the tips currently installed on

the nozzle bodies.

• NCV is the tip connected to the Hawkeye valve. The Bypass Tip is for secondary tips at each nozzle.

• If no tips are installed and liquid fertilizer is being applied, select 28% or 32% as the tip size.

8. Select the Next button to proceed to the Nozzle Indexing prompt.

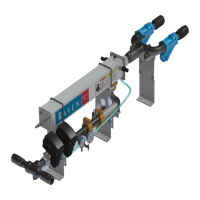

AUTOMATIC NOZZLE INDEXING

The automatic nozzle indexing process allows the Hawkeye system to automatically configure the location of each

nozzle control valve on the left and right boom circuits and may detect issues with system connection or nozzle

setup.

1. When prompted, select the Next button to begin the auto-indexing process.

2. Hawkeye will begin indexing nozzle control valves from the center of the implement boom and move out to

the end of the left boom. The indexing process automatically repeats for the right boom circuit, starting from

the center and working towards the end of the boom. If an error is detected on either the left or right boom

circuits, the Hawkeye ECU will halt the indexing process and prompt the machine operator to correct the error

before continuing with the calibration wizard. If an error occurs, troubleshoot the issue and press retry.

FENCE ROW SETUP

Fence row setup is only available if Sprayer was selected as the applicator type. If Applicator was selected, fence

row setup is skipped.

1. The Fence Row Setup prompt will display once the automatic indexing process completes.

2. Enable the fence option if fence row valves are connected to the system. Select the Enable On Screen Buttons

box to control fence row valves through the on-screen interface. If using secondary input switches to the boom

sense for fence rows, enter the appropriate section input for the left and right fence rows.

Loading...

Loading...