CHAPTER 3

22 Hawkeye Nozzle Control Operation Manual

6. Touch the Calibrate Pump button to initiate pump calibration. The pump will run until the ECU detects 1 oz. [0.3

dL] of chemical has been passed through the pump and the “Calibration Complete” message displays.

NOTE: If the console displays an error message during the calibration process, verify that the conditions from

step 5 exist. If the problem continues, refer to Troubleshooting section on page 61 for troubleshooting

steps.

7. Verify the calibrator plunger on the injection pump. The black ring should stop within the “window” markings

on the calibrator cover if calibration was successful. If the black ring stops outside of the calibration window, the

Flow Correction% value may be adjusted to compensate. Refer to the “System Settings Tab - Product Control”

section on page 37 for additional calibration instructions.

CATCH TEST

Prior to starting a chemical injection application, perform a catch test (if desired) to manually verify the pump

output before operation.

1. Verify the catch vessel is large enough to catch the desired volume.

2. Ensure the end of the hose going from the pump to the catch vessel has a check valve to prevent excess fluid

from exhausting when the pump has stopped pumping.

3. Set the hand valve on the injection pump outlet to pump the fluid to the catch vessel.

4. Ensure the pump and hose are primed as described in the “Pump Priming” section on page 19.

5. Verify the following conditions exist.

a. Injection pressure is less than 12 PSI [82.7 kPa].

b. Pump is off.

c. Vacuum pressure less than 11.5” of mercury [29 cm of mercury].

NOTE: The vacuum switch on the pump will engage and a flow alarm will display if the product cannot be

drawn into the tank (e.g. vacuum pressure at or above 11.5” or mercury [29 cm of mercury]). Check

screens, chemical tank lids, hose diameter and any hand valves between the chemical tank and pump

inlet for damage or obstructions. Also, verify the product if flowing freely. Cold temperatures and low

viscosity products may cause high inlet vacuum and cause the pump not to operate properly.

6. Press the Sidekick Pro ICD softkey for the desired pump product number.

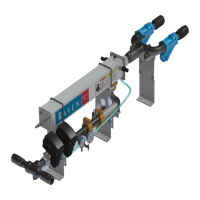

FIGURE 16. Sidekick Pro ICD Menu Button

7. Select the Diagnostics Information tab.

FIGURE 17. Diagnostics Information Tab

8. Press the Catch Test Menu button.

Loading...

Loading...