4

P/N 016-0171-584 Rev. D 29

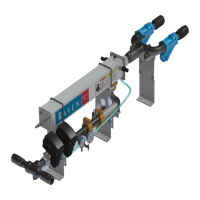

HAWKEYE™ NOZZLE CONTROL AND SIDEKICK PRO ICD SETUP

• Target Flow - Displays the target flow rate of the pump as set in the injection wizard or the

Hawkeye Home Screen.

• Actual Flow - Displays the actual flow rate of the pump during operation.

• Tank Level - Displays the volume remaining in the injection product tank.

• Pressure - Displays the pressure at the injection pump pressure transducer.

• Pump Efficiency - Displays the efficiency value of the pump during operation. Typical values range

from 60-100% and will vary depending on ambient temperature, product viscosity, system

plumbing, and system pressure.

• Motor RPM - Displays the motor RPM of the injection pump during operation.

• Node Voltage - Displays the voltage to the injection pump ECU. Typical operating values may

range from 10-16VDC.

• Motor Voltage - Displays the voltage to the injection pump motor. Typical operating values may

range from 10-16VDC.

• Motor PWM - Displays the motor PWM (between 0 to 100 %) value during operation.

• ECU Temperature - Displays the current temperature of the injection ECU.

• Engaged Hours - Displays the amount of time the pump has been actively pumping product.

SIDEKICK PRO ICD PRODUCT SETUP TAB

1. Open the VT Menu and select the desired Sidekick Pro ICD Menu button.

2. Select the Product Setup tab. The following information will display:

• Tank Capacity - Displays the capacity of the direct injection chemical supply tank in gallons (US) or

liters (SI).

• Tank Level - Displays the volume of product currently in the injection chemical supply tank. This

volume is used to calculate the volume remaining in the tank and for the low tank alarm if enabled.

• Flow Correction – Used to adjust the actual amount pumped by the injection pump for a given

target amount. A positive value will increase the amount pumped. A negative value will decrease

the amount pumped. If the volume caught during a catch test or pumped during normal operation

is less than the desired volume pumped, increase the Flow Correction % by the % difference. If the

volume caught is greater than the desired volume pumped, decrease the Flow Correction% by the

% difference. Typical error should be no more than +/-3%.

• Pressure Cal - Value used to calibrate the pump pressure transducer. Turn off the injection pump

and ensure there is no pressure at the pump outlet port or in the injection lines. Enter a value of

zero for the pressure calibration value after it has been verified there is no pressure at the

transducer.

• Agitator Enable - Enables the agitator feature. Check the box to enable the feature if agitation is

required and the system is equipped with the direct injection chemical supply tank agitation

system.

• Rinse Assist Equip - Enables the rinse assist feature. Check the box to enable the feature if the

injection system is equipped with the direct injection automated rinse system.

Sidekick Pro ICD Menu

Product Setup

Loading...

Loading...