P/N 016-0171-584 Rev. D 59

HAWKEYE NOZZLE CONTROL VALVE DIAGNOSTICS

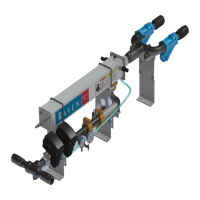

FIGURE 2. Advanced Nozzle Diagnostics

3. Select the Advanced Diagnostics button in the upper, left corner of the Nozzle Diagnostics prompt to access

the following diagnostic information for each nozzle:

NOTE: Use the left and right arrow buttons at the bottom of the nozzle prompt to view different nozzles.

NOZZLE OPERATION INFORMATION

Current and Voltage. Each nozzle control valve provides the measured current, in milliamperes, and voltage at

the nozzle to the Hawkeye main ECU for display. Use this information to assist with troubleshooting the nozzle

control valve bus if necessary or to check the integrity of the Hawkeye nozzle control system.

Duty Cycle Percent. Each nozzle reports the current nozzle duty cycle over the communication network for

display to the operator. Use this value to monitor the work load placed upon each nozzle.

Estimated Flow. The estimated flow rate through each nozzle is reported to the Hawkeye main ECU.

Target Flow. The target flow rate per nozzle for the current application.

Driver Temp and Micro Temp. Component temperatures on the Hawkeye nozzle control valve circuit board.

System Pressure. The monitored system pressure reported by the Hawkeye system pressure transducer.

Hardware Rev. Hardware revision information may be important for troubleshooting system issues or to update

nozzles. Review this information if necessary to ensure system functionality.

Nozzle Serial Number. The nozzle serial number for each nozzle is available on the nozzle diagnostics prompt.

This information may be used to help locate specific nozzles on the implement.

Program Version. The version of software loaded on each nozzle. This information may be helpful to

troubleshoot individual nozzles or to ensure proper operation of the nozzle control system.

CAN Address. The unique identifier assigned to each nozzle for communicating on the nozzle system is displayed

on the diagnostics prompt.

• Current • System Pressure

• Voltage (V) • Hardware Rev

• Duty Cycle Percent • Nozzle Serial Number

• Estimated Flow • Program Version

•Target Flow •CAN Address

• Driver Temp • Runtime Hours

• Micro Temp • Pump Duty Cycle

• Flow Offset Enable

Nozzle Select

Exit Diagnostics

Screen

Loading...

Loading...