Chapter 4

28 Sidekick Pro Installation & Operation Manual

Pressure Transducer Calibration

Before operating the Sidekick Pro system, calibrate the pressure transducers which monitor both the injected

chemical and carrier product pressures.

Pressure of the injected product is monitored by a pressure transducer connected to the Sidekick Pro pump.

Pressure of the carrier product is monitored by an optional boom or carrier product line pressure transducer.

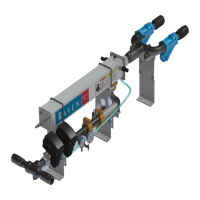

FIGURE 2. Optional Boom Pressure Transducer Location

Note: The boom or carrier pressure transducer may be installed either as shown in the figure above or

upstream of the point of injection.

Sidekick Pro uses these pressure transducers to verify injection status and for error detection.If an

optional carrier or boom pressure transducer is not installed, the Sidekick Pro will not provide low

pressure alarms during chemical injection applications.

Calibrating the Pump Transducer

Note: The following process offers a general overview of calibrating or resetting the Sidekick Pro pump

pressure transducer Refer to the operation manual for the specific control console for detailed

navigation and calibration of the pressure transducer or pressure display.

1. Turn off the injection pump and product control system and ensure

1. Select or display the set up screens for the correct product.

2. Turn off the injection pump and product control system and ensure no product pressure in the injection

lines.

3. Enter a value of zero for the pressure calibration value.

Optional Boom

Pressure Transducer

Loading...

Loading...