RG55T-R Operation • Service • Maintenance

44

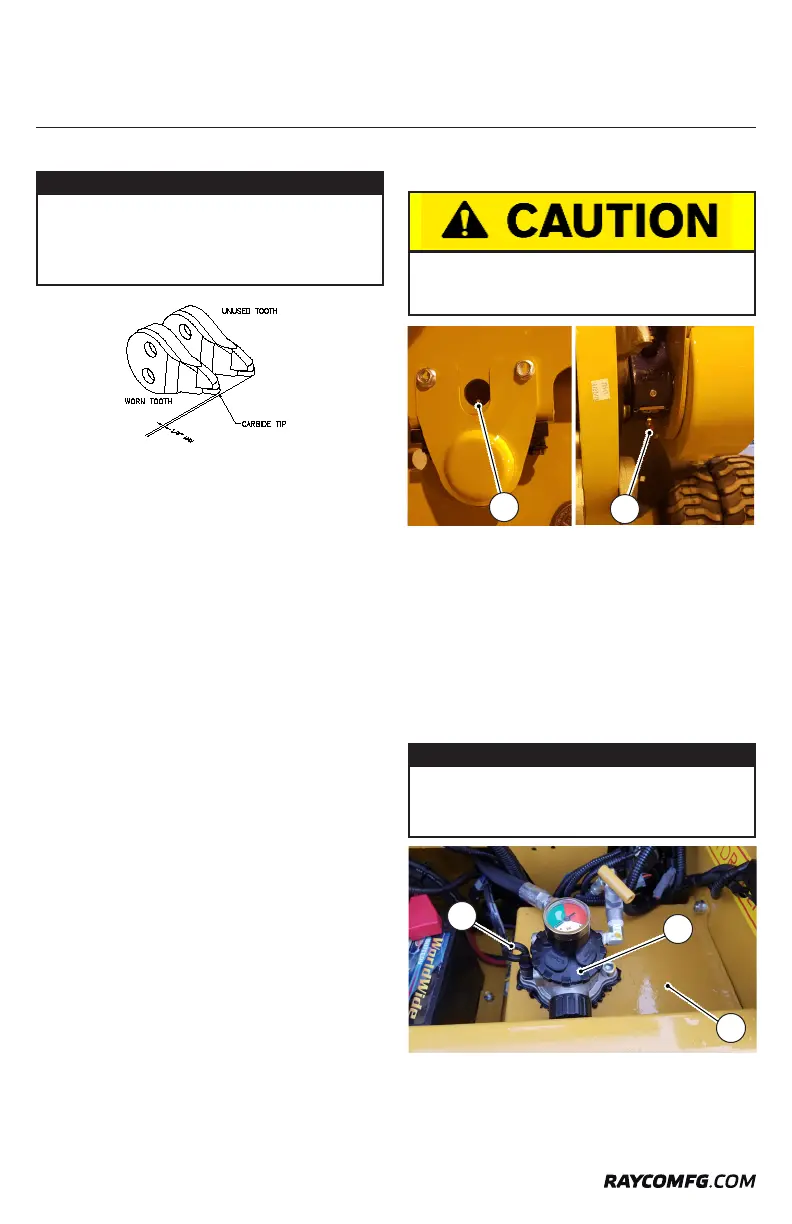

Sharpening Teeth

DO NOT allow any tooth to wear too much before sharpening.

Discard any tooth that has lost more than 1/8” of original bite.

Remove the tooth from the cutting wheel to be sharpened.

Tooth Sharpening Guidelines:

1. Obtain an unused tooth for comparison.

2. Discard any tooth that has lost more than 1/8” of original

bite, whether lost through usage or grinding.

3. Grind off a minimal amount from the end, just enough

to restore the original taper and radius on the end. The

end of the cemented carbide tip and the end of the steel

shank should be flush after grinding.

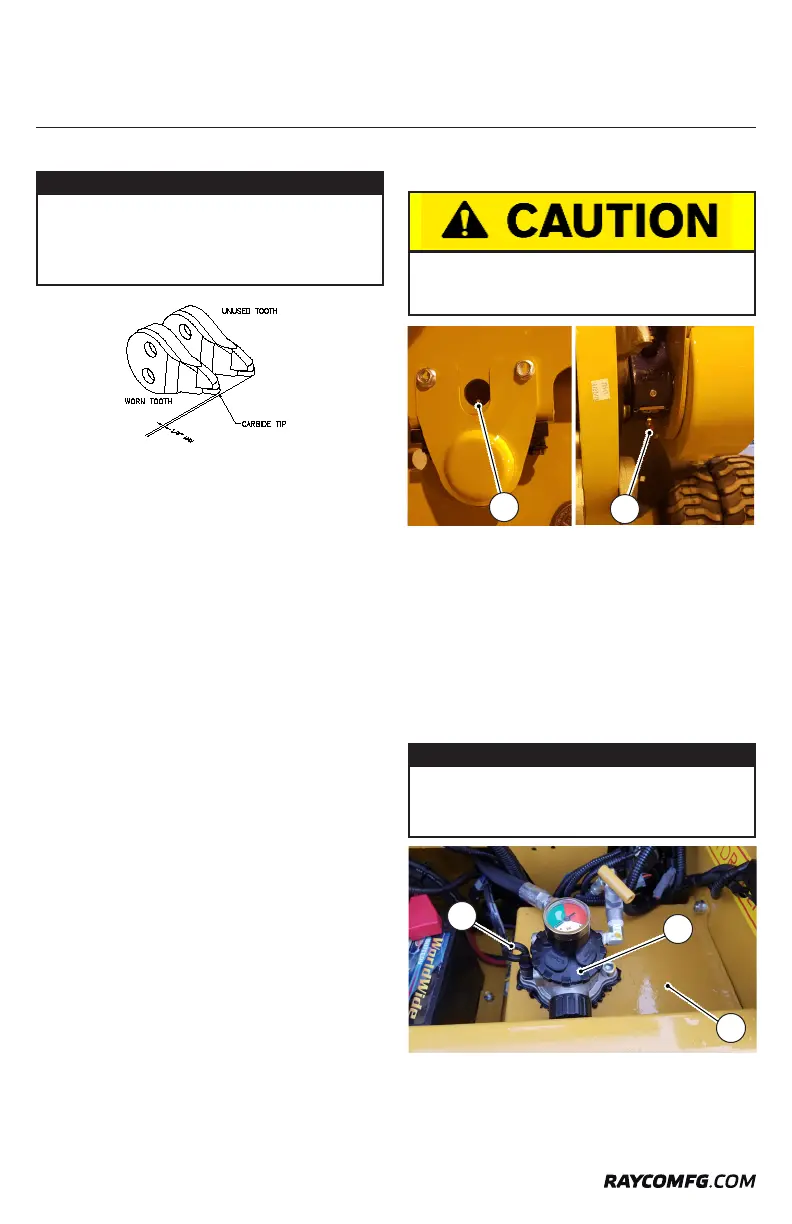

Cutter Wheel Bearings

Lubricate

Lubricate both cutter wheel bearings zerks(1) fitting DAILY.

There is a cutter wheel bearing on each side of the cutter wheel.

• Fill with high-temperature (NLGI 2) grease until you can

visually see the old grease purge itself out all the way

around the seal diameter and new grease beginning

to purge out.

This will ensure that the dirt and debris that gets collected

inside the seal area is flushed away from the internal bearings

thus providing longevity to the bearing and races.

Hydraulic Oil

The hydraulic oil tank (reservoir) (2) is located next to the

battery. The oil level can be checked with the dipstick (3). The

oil level should be 1/2” up on the dipstick, and not exceede

3/4”at any given time to allow for expansion.

Maintenance

NOTICE

Sharpening cemented carbide cutting teeth requires

a special process. Have your teeth sharpened only

by a qualified machinist for obtaining a proper edge

and to avoid injury.

NOTICE

Replace oil if it smells burnt or appears to be dirty.

Use only clean, fresh hydraulic oils, free of bubbles.

(bubbles indicate low hydraulic oil level.)

4

3

2

1

BE SURE TO SHUT DOWN THE MACHINE, AND

ENGINE BEFORE LUBRICATING THE CUTTER

WHEEL BEARINGS

1

Loading...

Loading...