Rexroth IndraDyn A Application Notes 9-23

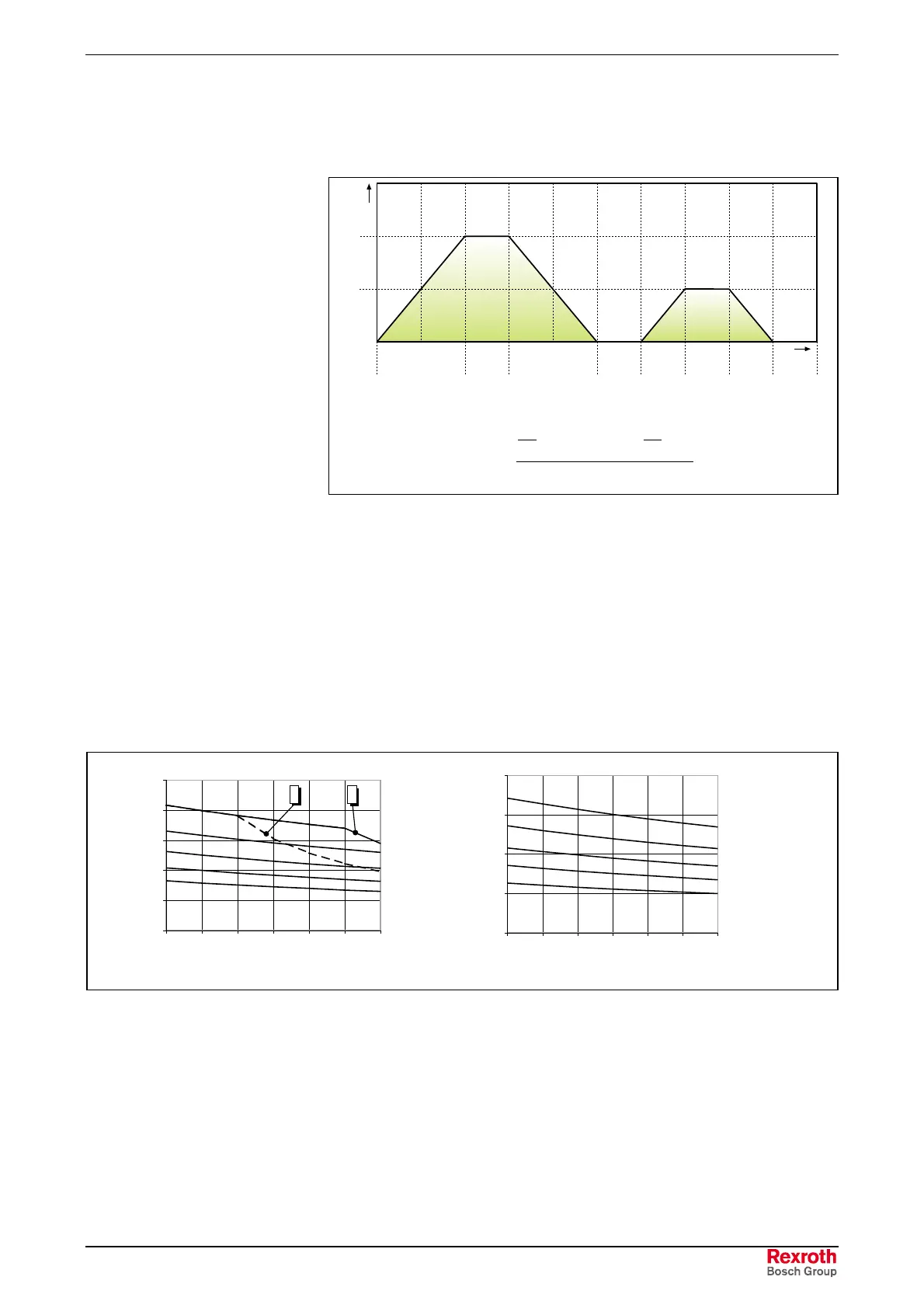

significantly greater than the acceleration and deceleration times. In the

exact calculation of the mean speed according to the following example,

the acceleration and deceleration times are taken into account.

n

t

t

H1

t

1

t

B1

t

11

t

H2

t

2

t

B2

t

22

n

1

n

2

Average.EPS

111B11H

1B

1

111H

1

m1

tttt

t

2

n

tnt

2

n

n

+++

⋅+⋅+⋅

=

n

1m

: mean speed in section 1 n

2m

: mean speed in section 2

n

1

: processing speed n

2

: processing speed

t

H1

: acceleration time t

H2

: acceleration time

t

1:

processing time t

2:

processing time

t

B1

: deceleration time t

B2

: deceleration time

t

11

: standstill time t

22

: standstill time

Fig. 9-26: Mean speed

A complete operating cycle can consist of several sections with different

speeds. In this case, the average is to be generated from all the sections.

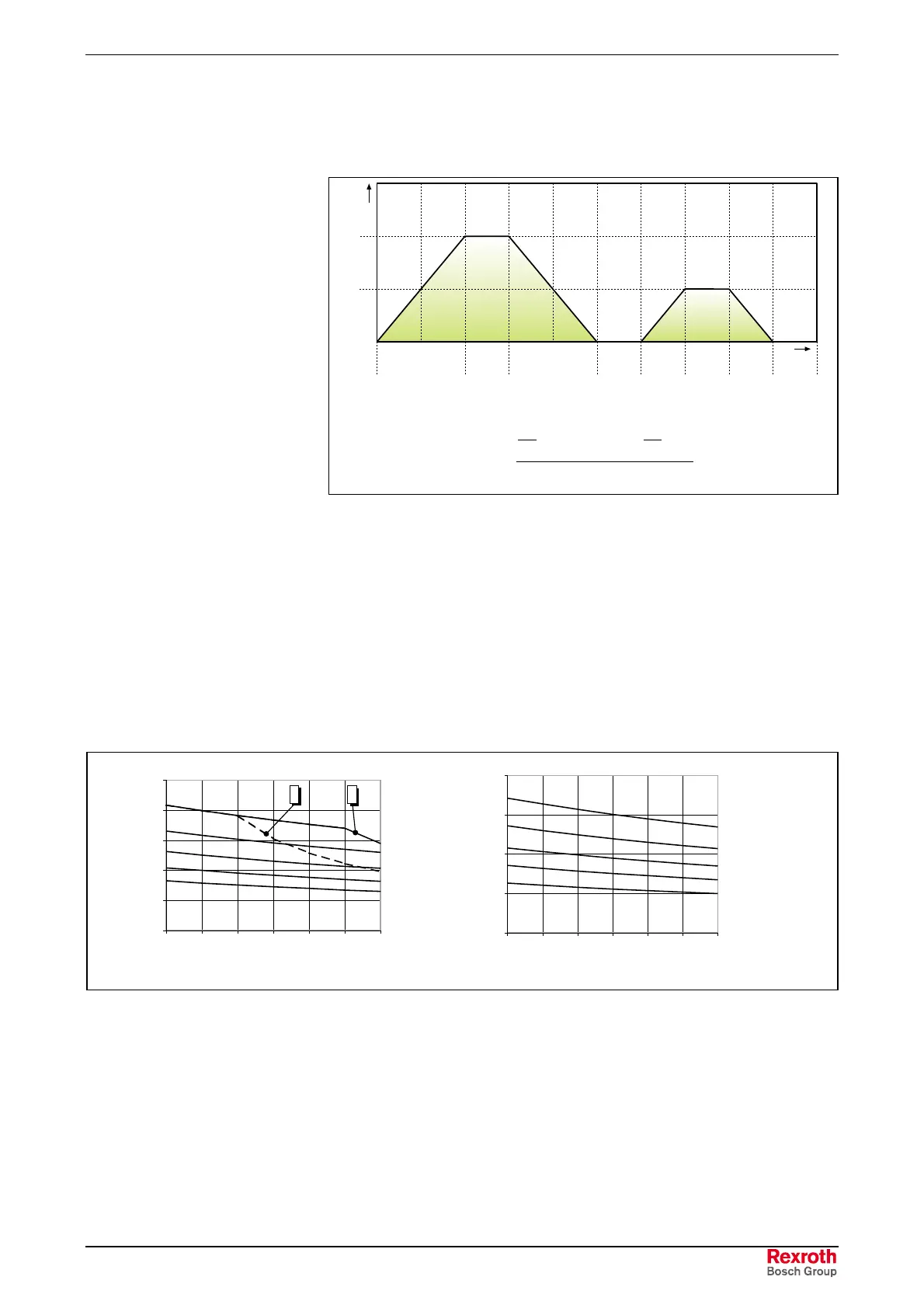

Type "N" / "R"

n

m

= 1000 min

-1

n

m

= 2000 min

-1

n

m

= 4000 min

-1

n

m

= 8000min

-1

2

n

m

= 500 min

-1

1

0

1

2

3

4

5

0 102030405060

x [mm]

Fr [kN]

Type "H"

n

m

= 500 min

-1

n

m

= 1000 min

-1

n

m

= 2000 min

-1

n

m

= 4000 min

-1

n

m

=10000min

-1

0

0,5

1

1,5

2

0 102030405060

x [mm]

Fr [kN]

Wellenbelastung MAx100.EPS

"N": Standard bearings

“R“: Bearing for coupling attachment

”H”: High-speed bearing

(1): Load limit for drive shaft without keyway

(2): Load limit for drive shaft with keyway

n

m

: Mean speed

Fig. 9-27: Shaft load, Motor-frame size 100 (L

h

=30,000 operating hours)

Shaft Load, Size 100

Loading...

Loading...