Rexroth IndraDyn A Installation 11-1

11 Installation

11.1 Safety

WARNING

Injuries due to live parts! Lifting of heavy loads!

⇒ Install the motors only when they are de-energized

and not connected electrically.

⇒ Use suitable lifting equipment, protective equipment

and protective clothing during transport.

⇒ Do not lift or move the motor by the fan unit.

⇒ Observe the safety notes found in previous chapters.

Carry out all working steps especially carefully. In this way, you minimize

the risk of accidents and damages.

IndraDyn A motors from frame size 130 have additional threaded

holes on their long sides for inserting eyelets (for details, see the

dimension sheet). Additional eyelets can simplify handling and transport.

11.2 Mechanical Attachment

Mounting Holes

IndraDyn A motors are manufactured either for flange mounting

(structural shape 05) or for foot mounting (structural shape 35). Details for

the fastening holes can be found in the corresponding dimension sheet.

For mounting, the following general assignment applies:

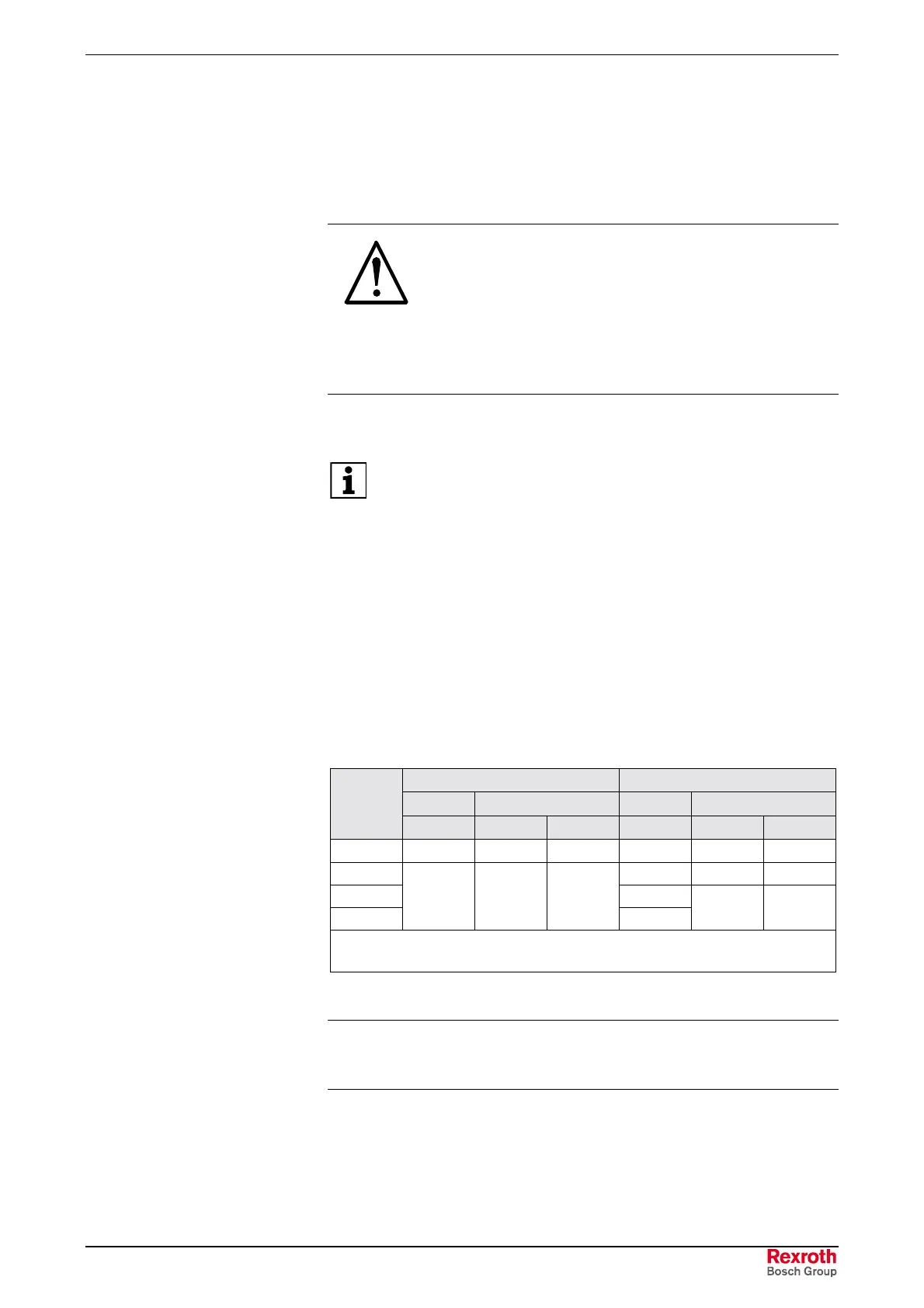

B05 (flange assembly) B35 (Foot assembly)

Hole Bolt 1) Hole Bolt 1)

MAD/MAF

Ø [mm] Type M

GA

[Nm] Ø [mm] Type M

GA

[Nm]

100 14 M12 87 11 M10 51

130 12 M10 51

160 14

180

18 M16 215

14,5

M12 87

1) Type and torques as recommendations for bolts of fastening class 8.8.

M

GA

= Torque in Newton-meters.

Fig. 11-1: Mounting holes

Note: The threaded connections must be able to take up both the

force due to the weight of the motor and the forces acting

during operation.

Loading...

Loading...