10-18 MKD112 Synchronous Motors MKD

19.05.2004 Version7.0 DOK-MOTOR*-MKD*******-PR07-EN-P

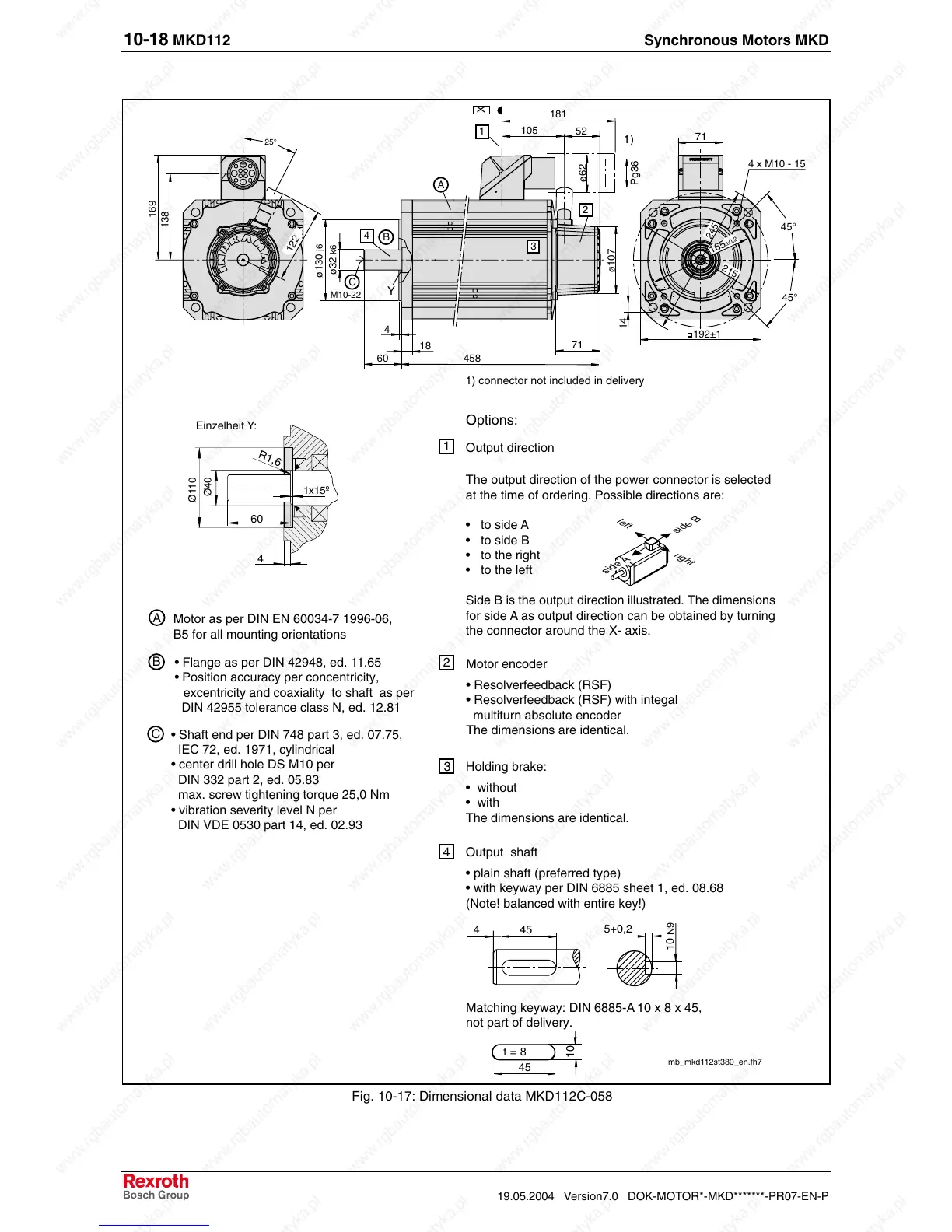

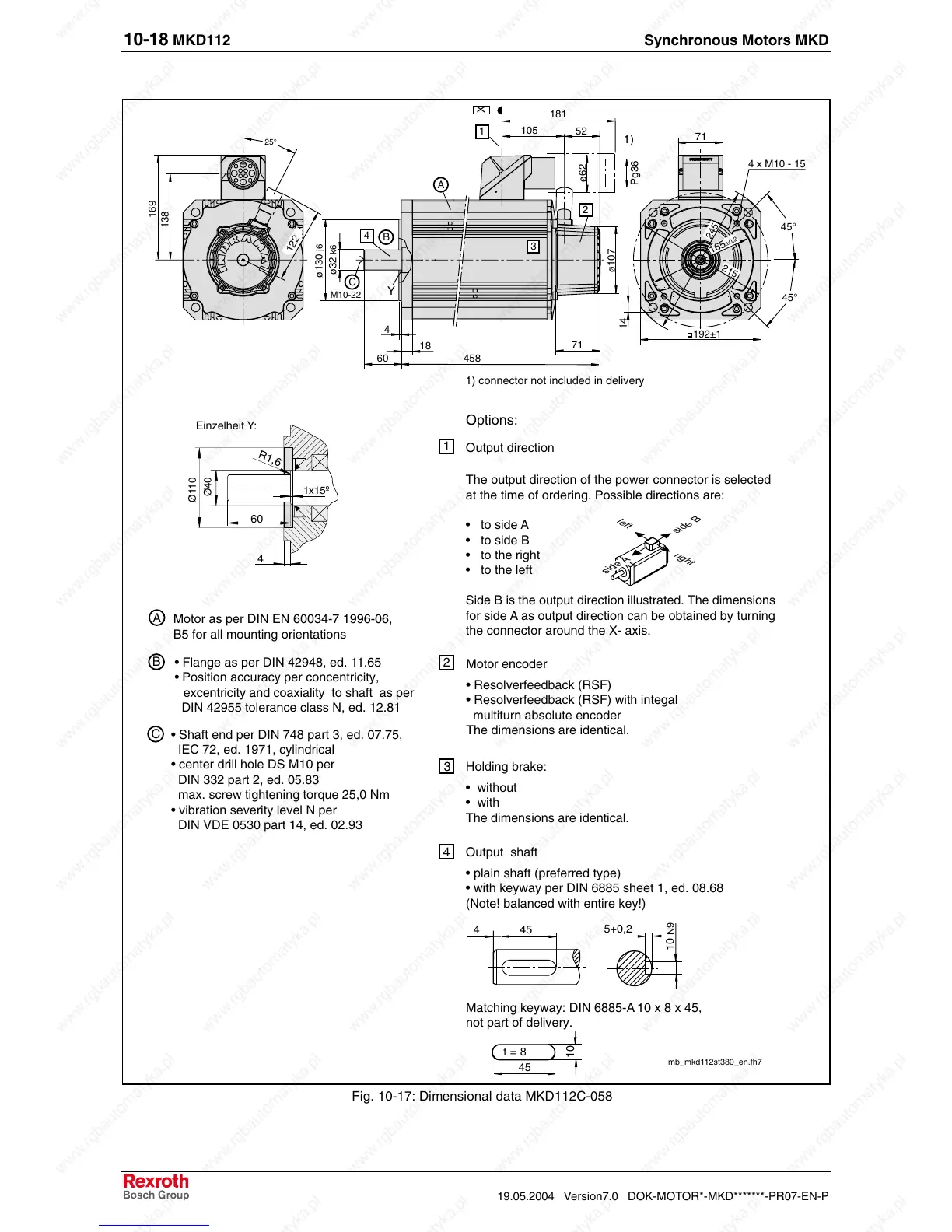

Y

2

25°

138

169

122

3

B

C

A

ø130 j6

ø32 k6

M10-22

181

105

1

X

52

1)

ø107

18

60

71

458

A

4

ø62

Pg36

71

45°

45°

14

192±1

4 x M10 - 15

165

±0,2

245

215

B

4

C

R1,6

60

4

Einzelheit Y:

Ø40

1x15º

Ø110

Motor as per DIN EN 60034-7 1996-06,

B5 for all mounting orientations

• Flange as per DIN 42948, ed. 11.65

• Position accuracy per concentricity,

excentricity and coaxiality to shaft as per

DIN 42955 tolerance class N, ed. 12.81

• Shaft end per DIN 748 part 3, ed. 07.75,

IEC 72, ed. 1971, cylindrical

• center drill hole DS M10 per

DIN 332 part 2, ed. 05.83

max. screw tightening torque 25,0 Nm

• vibration severity level N per

DIN VDE 0530 part 14, ed. 02.93

mb_mkd112st380_en.fh7

45

5+0,2

10

N9

Options:

4

Output direction

The output direction of the power connector is selected

at the time of ordering. Possible directions are:

• to side A

• to side B

• to the right

• to the left

Side B is the output direction illustrated. The dimensions

for side A as output direction can be obtained by turning

the connector around the X- axis.

2

1

3

4

45

10

t = 8

Matching keyway: DIN 6885-A 10 x 8 x 45,

not part of delivery.

1) connector not included in delivery

Motor encoder

• Resolverfeedback (RSF)

• Resolverfeedback (RSF) with integal

multiturn absolute encoder

The dimensions are identical.

Holding brake:

• without

• with

The dimensions are identical.

Output shaft

• plain shaft (preferred type)

• with keyway per DIN 6885 sheet 1, ed. 08.68

(Note! balanced with entire key!)

side A

side B

left

right

Fig. 10-17: Dimensional data MKD112C-058

Loading...

Loading...