16-4 Startup, Operation, and Maintenance Synchronous Motors MKD

19.05.2004 Version7.0 DOK-MOTOR*-MKD*******-PR07-EN-P

Changing the battery

Drive control systems of Rexroth observe voltage of battery safely and

give just in time a warning “change battery”.

Changing the battery should be made, when machine is under load. This

is necessary to avoid an overrun in the motor encoder (switch off control

voltage can cause loss of absolute values).

Following tools and spare parts are needed:

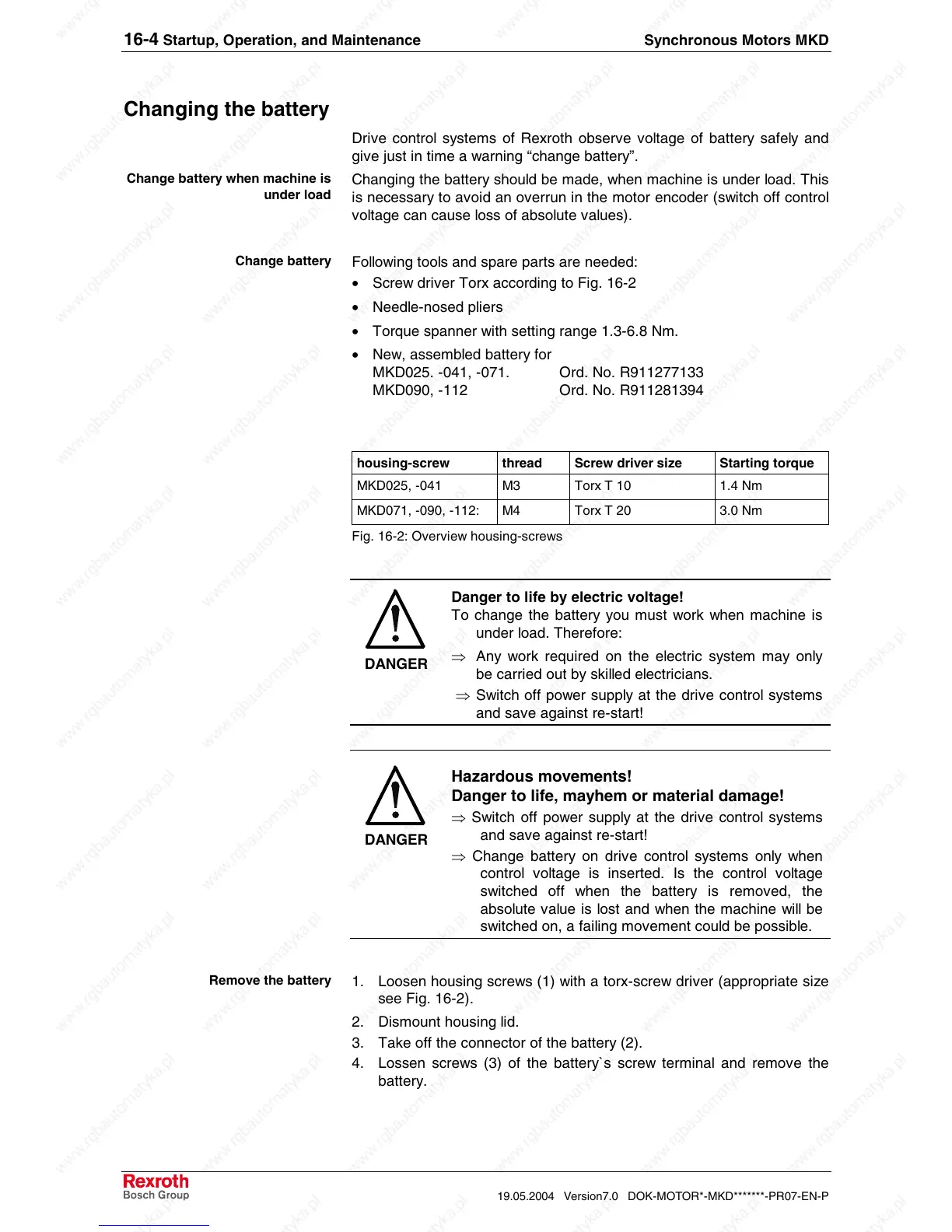

• Screw driver Torx according to Fig. 16-2

• Needle-nosed pliers

• Torque spanner with setting range 1.3-6.8 Nm.

• New, assembled battery for

MKD025. -041, -071. Ord. No. R911277133

MKD090, -112 Ord. No. R911281394

housing-screw thread Screw driver size Starting torque

MKD025, -041 M3 Torx T 10 1.4 Nm

MKD071, -090, -112: M4 Torx T 20 3.0 Nm

Fig. 16-2: Overview housing-screws

DANGER

Danger to life by electric voltage!

To change the battery you must work when machine is

under load. Therefore:

⇒ Any work required on the electric system may only

be carried out by skilled electricians.

⇒ Switch off power supply at the drive control systems

and save against re-start!

DANGER

Hazardous movements!

Danger to life, mayhem or material damage!

⇒ Switch off power supply at the drive control systems

and save against re-start!

⇒ Change battery on drive control systems only when

control voltage is inserted. Is the control voltage

switched off when the battery is removed, the

absolute value is lost and when the machine will be

switched on, a failing movement could be possible.

1. Loosen housing screws (1) with a torx-screw driver (appropriate size

see Fig. 16-2).

2. Dismount housing lid.

3. Take off the connector of the battery (2).

4. Lossen screws (3) of the battery`s screw terminal and remove the

battery.

Change battery when machine is

under load

Change battery

Remove the battery

Loading...

Loading...