Form I-MAPSIII&IV, P/N 222917R9, Page 63

9.2.3.2 Venting and

Combustion Air -

MAPS

®

III Cabinet D

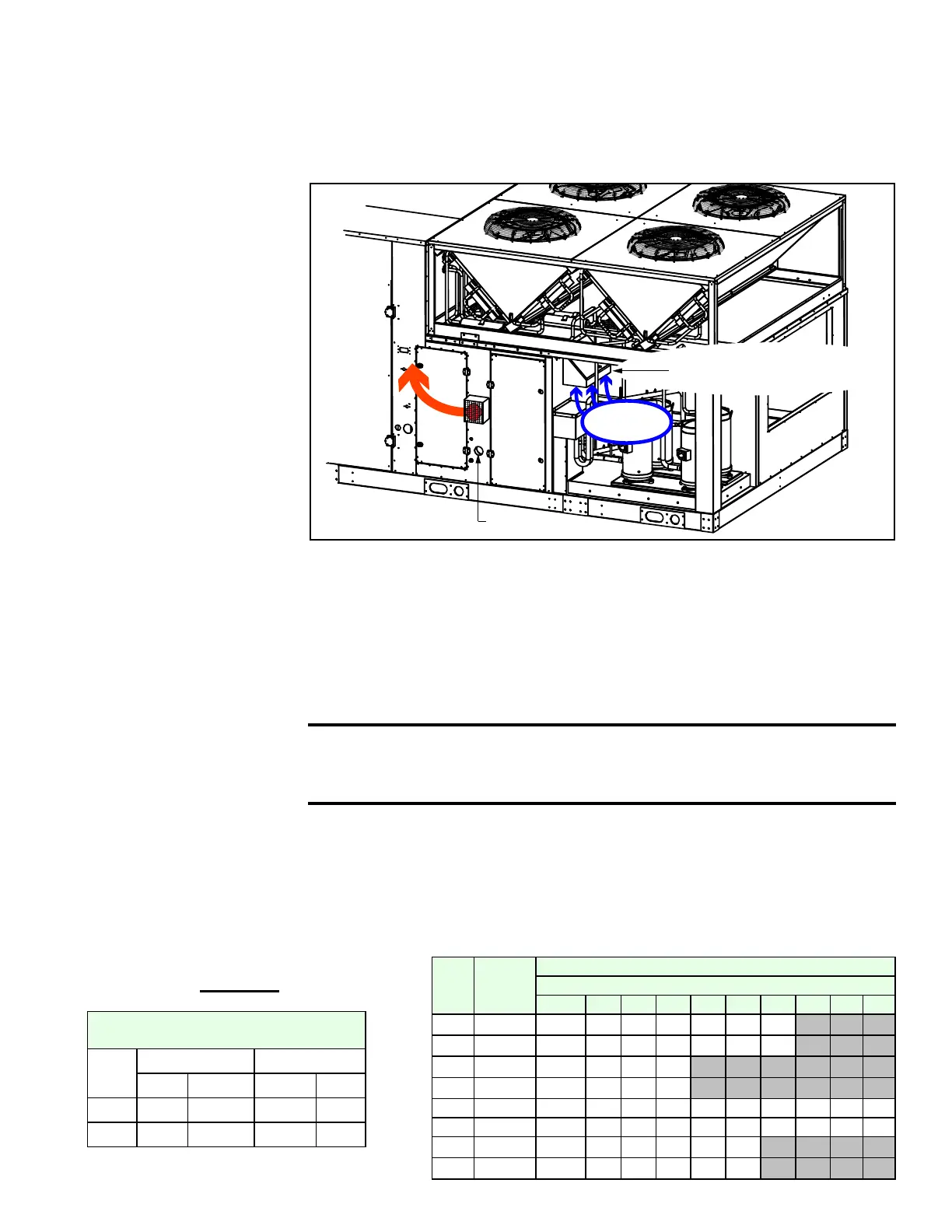

FIGURE 46 - Heat

Section Showing

Location of Flue

Exhaust (vent) and

Combustion Air Hood -

Cabinet D Sizes

Heat

Section

Door

Gas Entrance

Combustion

Airflow

Combustion Air Inlet Hood

Vent

NOTE: The illustration

shows only one furnace.

The combustion air hood is

in the same location when

the heat section has two

furnaces. Each furnace has

a vent.

On a D Cabinet, a screened vent cover was attached to each vent (ue exhaust) in

Paragraph 9.2.1.

The gas-red heat section vents combustion gas horizontally. A eld-installed vent

extension kit (P/N 221120) provides for attaching a vertical vent pipe that will allow the

vent terminal to extend above the unit. For information, contact your distributor or see

Form CP-MAPS-Vnt Ext on www.RezSpec.com.

Vent Extension Field Kit

for MAPS

®

Cabinet A, B,

or C

All gas furnaces are equipped with a temperature activated auto reset limit control. The

control is factory set at 270°F and is non-adjustable. If the setpoint is reached, the limit

control will interrupt the electric supply to the gas valves. This safety device provides

protection in the case of a lack of airow due to dirty lters or a restriction at the inlet

or outlet.

The limit control switch is mounted on the side of the heat exchanger with a capil-

lary sensor that extends across the discharge opening. The switch is accessible in

the blower cabinet of a MAPS

®

Cabinet A, B, or C system or in the heat module of a

MAPS

®

III Cabinet D system.

CAUTION: The auto reset limit control will continue to shut down

the heat section until the cause is corrected. Never bypass the

limit control; hazardous conditions could result.

9.2.4 High

Temperature Limit

Control - All MAPS

®

Cabinet Sizes

9.3 Electric Heat -

Models RECB,

REDB, RECC,

REDC

A MAPS

®

unit with an electric heat section is equipped to provide from 5 to 88 kw of

electric heat. Depending on the size, electric heat sections provide one or three stages

of heating operation or can be equipped with optional SCR modulating control.

Call for heat and staging occur in response to system controls (See Paragraph 8).

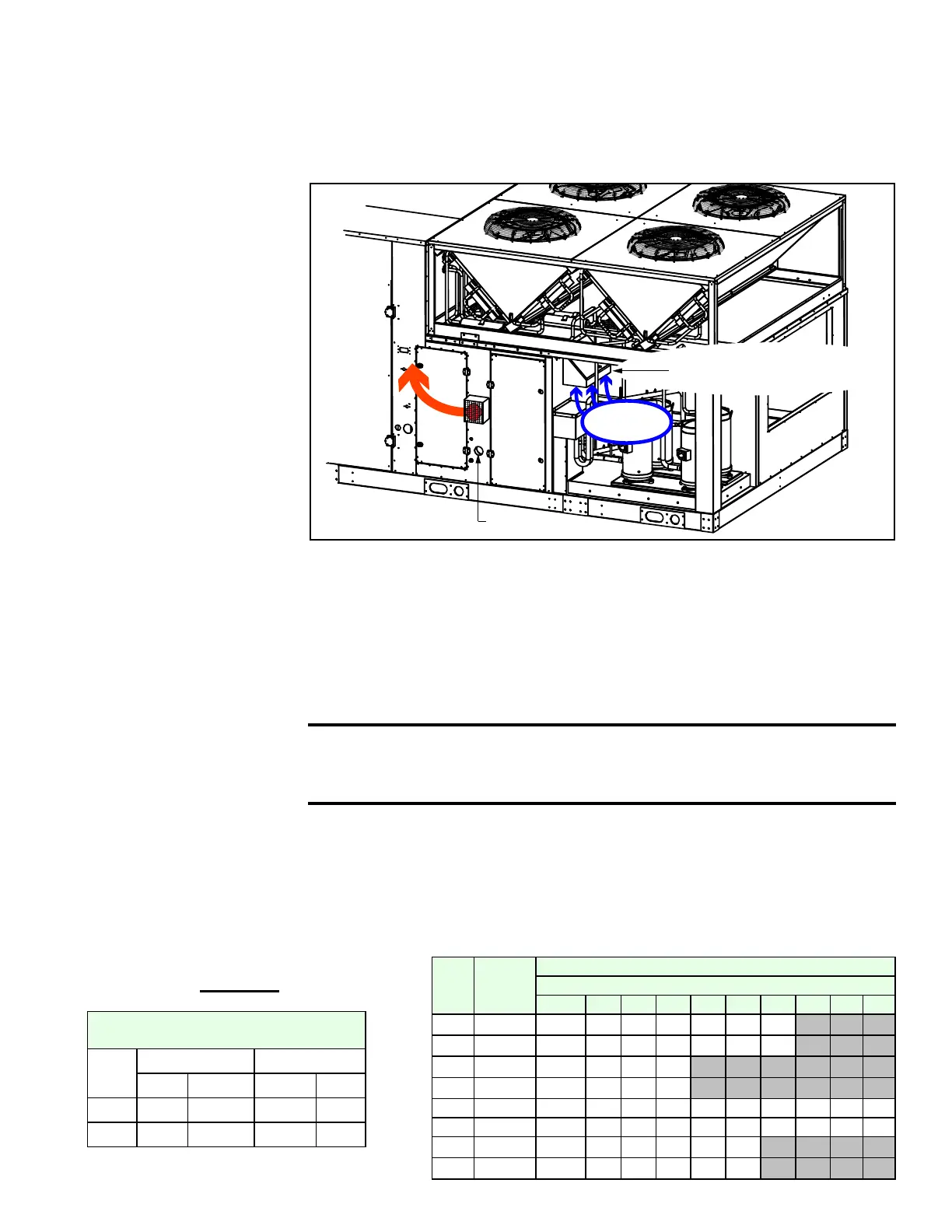

9.3.1 Electric Heat

Size

(kW)

Voltage

Electric Heaters Sequence of Operation

Stage

1 2 3 4 5 6 7 8 9 10

120 208 10 10 20 20 20 20 20

120 240 10 10 20 20 20 20 20

120 480 30 30 30 30

120 575 30 30 30 30

180 208 10 10 20 20 20 20 20 20 20 20

180 240 10 10 20 20 20 20 20 20 20 20

180 480 30 30 30 30 30 30

180 575 30 30 30 30 30 30

Electric Heat Capacity Table

- D Cabinet

Size

240/480/575V 208V

KW MBH KW MBH

120 120 410 90 307

180 180 615 135 461

Electric Heat Capacity and Sequence

of Operation - Cabinet D

Loading...

Loading...