Page 6

8. Location and

Mounting

7. Rigging

All cabinets are furnished with a curb cap and four lifting lugs for attaching

rigging. To prevent damage to the cabinet, use spreader bars with the rigging

chains.

Mounting the system is the responsibility of the installer. Verify that the sup-

porting structure has sufficient load-carrying capacity to support the weight.

NOTE: Net weights are approximate for the standard system. Optional equip-

ment is not included.

Mounting on Field-

Supplied Supports

The system is equipped with a load-bearing curb cap which forms an integral

part of the unit. The curb cap provides required clearance from combustibles.

Whether the system is being mounted directly on a surface or being placed

"up" on additional structure, the horizontal length must be supported by two

4x4 treated wooden rails. Refer to FIGURE 3 for the appropriate lengths and

spacing. When the system is placed on the rails, the curb cap "skirt" must fit

over the edge of the boards with the rails setting inside the horizontal length of

the curb cap.

If the rails are laid directly on the mounting surface, position them as shown in

FIGURE 3. Set the system on the rails leaving the "ends" underneath open for

ventilation.

If the wooden rails are not placed directly on a surface, cross-supports should

be placed underneath the rails at the ends and at the cabinet "joint". Refer to

FIGURE 4.

IMPORTANT NOTE: Mount an outdoor unit with a minimum of 14" clear-

ance from the bottom of the inlet air hood to the mounting surface.

Depending on the building and its use, determine whether or not additional

measures should be taken to reduce the effect of blower vibration and/or noise.

When selecting a location for an outdoor installation, position the unit so that

the air inlet will NOT be facing into the prevailing wind. A minimum of 14"

(356mm) clearance is required from the bottom of the air inlet hood to the

mounting surface.

Prior to installation, be sure that the method of support is in agreement with all

local building codes. For both indoor and outdoor installations, check for ser-

vice platform requirements. If an outdoor system is being installed with bot-

tom discharge and/or return air, a full perimeter roof curb is recommended.

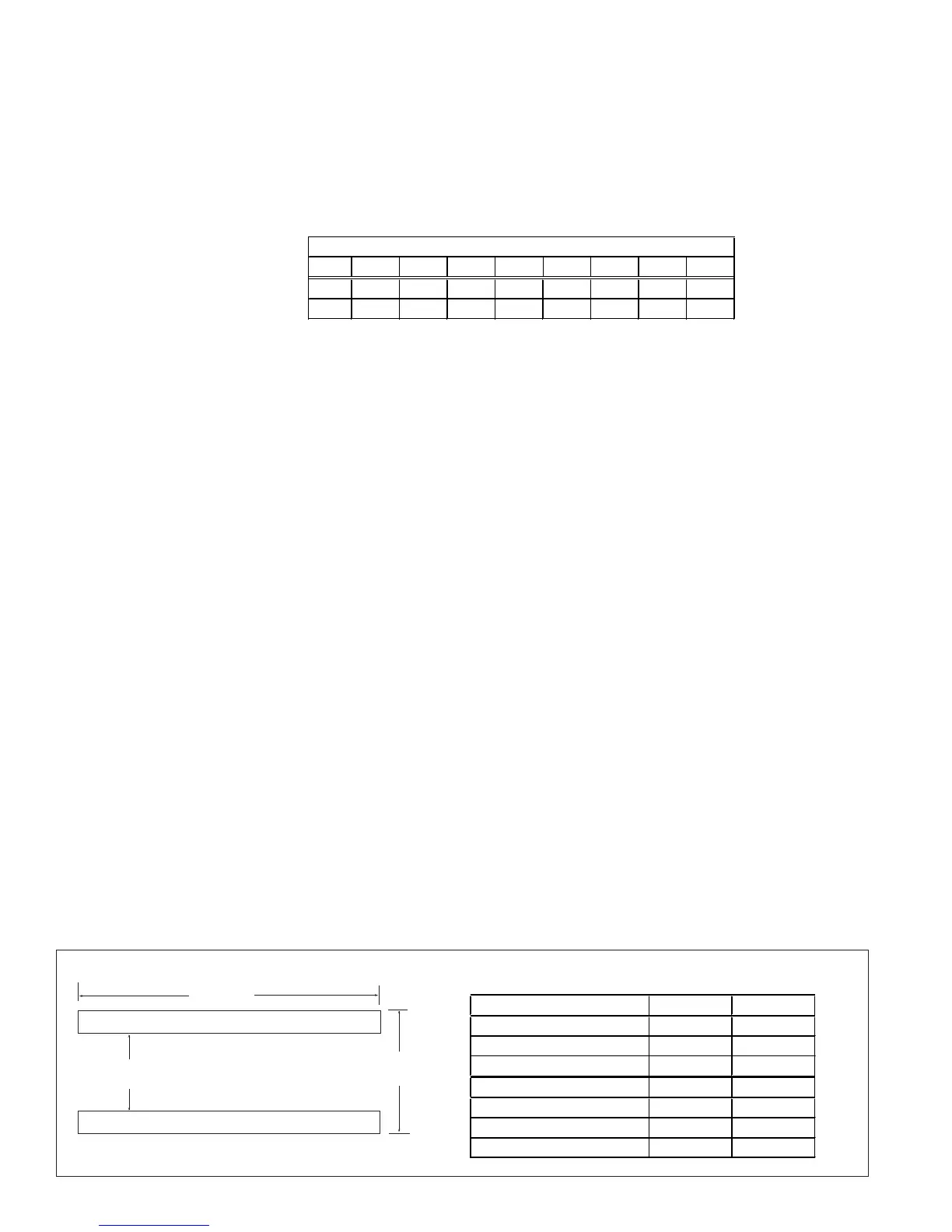

FIGURE 3 - Placement of

Mounting Rails

A

B

4 x 4 Treated Lumber

Weights

Net Wei

ht of Basic S

stem

Sizes

1-20 1-40 1-50 1-65 2-80 2-120 3-180 3-260

lbs 915 925 935 950 1455 1505 2410 2480

kg 415 420 424 431 670 683 1093 1125

Mounting Rail Placement

Model A (inches) B (inches)

1-20, 1-40, 1-50, 1-65

85-1/4 45-1/2

2-80, 2-120

85-1/4 69-7/16

3-180, 3-260, 122, 130

132-5/8 83-1/16

Model A (mm) B (mm)

1-20, 1-40, 1-50, 1-65 2165 1156

2-80, 2-120 2165 1764

3-180, 3-260 3369 2110

Loading...

Loading...