26

- Any external circuits connected to the outputs of the control board, must be carried out to

make sure the double or reinforced insulation is used compared to parts with hazardous

voltage.

- All the inputs are run by a programmed integrated circuit which carries out an auto-test at

every start-up operation.

MAINTENANCE CHECK

N.B.: During this check the safety functions Edges, Photocells, Stop button and Impact

detection are NOT active.

1 - Set DIP 1 to ON => LED DL1 starts to flash.

2 - Press and hold the PROG button (the command is hold-to-run, open-stop-close-stop-

open-etc ...) => The gate starts at high speed and then slow down until the limit switch

is reached.

3 - At the end, put DIP 1 back to the OFF position. The DL1 LED turn off signaling the exit

from the check.

If the motor does not work during this check, check the connections and its capacitor.

If the motor is working properly, check the safety devices.

TROUBLE SHOOTING

After having carried out all connections, by carefully following the layout and having positioned

the gate in intermediate position, check the correct ignition of red LEDS DL6, DL7, DL8 and

DL9.

In case of no ignition of the LEDS, always with gate in intermediate position, check the

following and replace any faulty components.

DL6 OFF Stop button malfunction (if Stop is not connected, perform

the jump between COM A+ and STOP).

DL7 or DL8 OFF Faulty photocells (In case the edge is not connected, carry

out jumper between COM A+ and PHOTO 1/PHOTO 2)

DL9 OFF Faulty safety edge (In case the edge is not connected, carry

out jumper between COM A+ and EDGE)

LED DL13 (BLUE) ON Some functions are enabled via smartphone, so via

smartphone check the card functions as the dips/trimmers status may not be true.

On the board there are resettable fuses which intervene in the event of a short circuit,

interrupting the output assigned to them.

In the event of troubleshooting, it is advisable to disconnect all the removable

connectors and insert them one at a time in order to more easily identify the cause

of the fault.

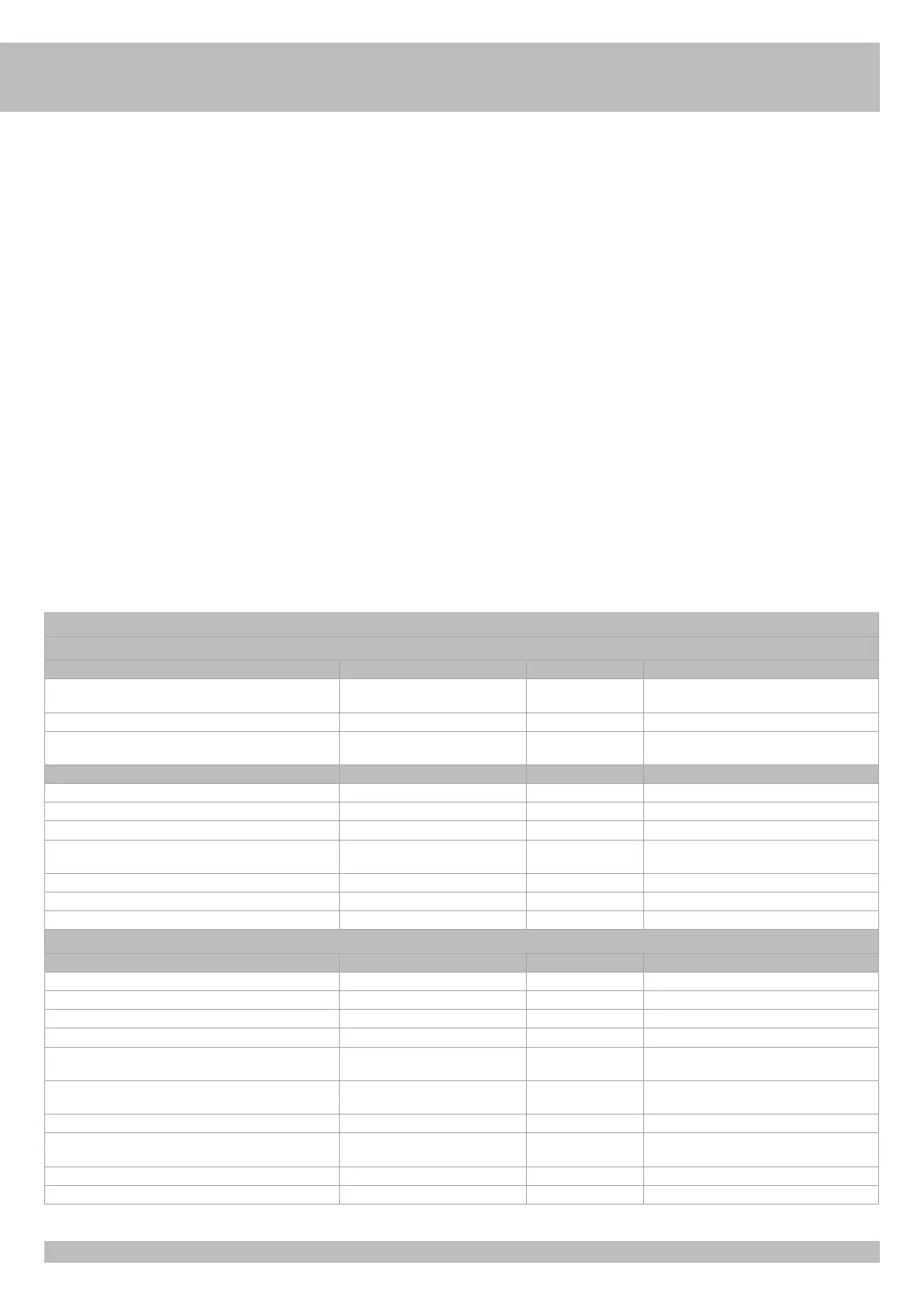

TABLE SUMMARISING VISUAL AND SOUND ALARMS

SIGNALS DURING PROGRAMMING SEQUENCE

EVENT BUZZER STATUS FLASHER STATUS DL1 LED STATUS

Dip 1 ON (hold-to-run mode)

Or failure of a safety device

Off Off Flashes on-off 250 ms

Dip 2 ON (stroke programming) Off Off Flashes on-off 500 ms

Programming sequence stopped due to intervention of a safety

device

10 seconds tone with 2 seconds pause Off On steady

EVENT BUZZER STATUS FLASHER STATUS DL12 LED STATUS

No transmitter code entered Off Off Flashes intermittently red/green

Dip 1 > 2 - transmitter code programming for full opening Off Off Flashes red for 10 seconds

Dip 1>2> 3 - transmitter code programming for R-AUX relay Off Off Flashes orange for 10 seconds

Correct transmitter codes programming for opening and R-AUX

relay

1 Tone Off Turns green once

Remote control code not present in memory Off Off Turns red once

Memory saturated by remote control codes (1000 codes saved) Off Off Runs 6 green flashes

Radio code deletion for opening and R-AUX relay 2 Tones Off Runs 2 green flashes

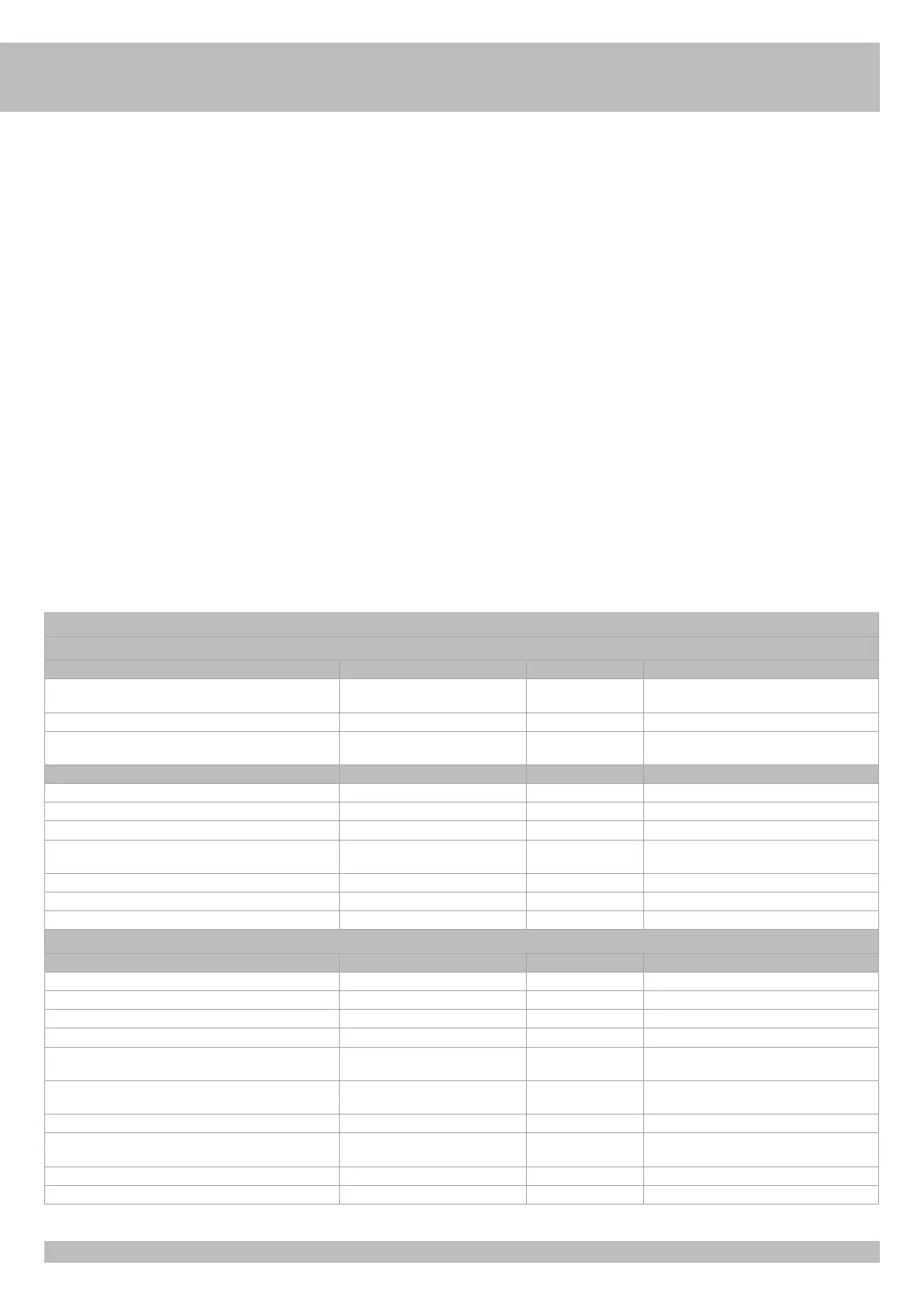

WARNING SIGNALS DURING OPERATION

EVENT BUZZER STATUS FLASHER STATUS LED STATUS AND SIGNAL OUTPUT

Stop button pressed Off Off Led DL6 turns off

Photocell intervention 1 Tone Off Led DL7-8 turns off

Edge intervention 2 Tones Off Led DL9 turns off

Failure of a safety device or safety device engaged for too long Off Off Led DL1 flashes on-off 250 ms

Alarm from edge 2 Tones every 5 seconds for 1 minute

(It is renewed by giving a command)

Enabled for 1 minute No led combined

Failed photocells auto-test alarm 4 Tones every 5 seconds for 1 minute

(It is renewed by giving a command)

Off No led combined

Functional block activated by smartphone Off Off Led DL12 is steady on green.

Achievement of set cycles 6 Tones every 5 seconds

(It is renewed by giving a command)

Off No leds matched

Energy saving activated by smartphone Off Off Blue led flashes once every 5 seconds

Alarm - no limit switches reached or unlocked barrier 5 Tones Enabled for 1 minute No leds matched

G

B

Loading...

Loading...