2902

5

GB

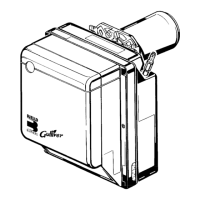

3.3 FUEL SUPPLY

The burner is designed to allow entry of the oil supply pipes on either side.

Depending on the oil supply pipes position (to the right or to the left hand side of the burner) the fixing plate

(1) and cable clamp (2) should be reversed, (see fig. 6).

3.4 HYDRAULIC SYSTEMS

➤

It is necessary to install a filter on the fu-

el supply line.

■

The pump is designed to allow working with

two pipes

.

■

In order to obtain one pipe working it is nec-

essary to unscrew the return plug (2),

remove the by-pass screw (3) and then

screw again the plug (2) with a torque of

0.5 Nm.

■

Before starting the burner make sure that

the return pipe-line is not clogged. An

excessive back pressure (Š 1 bar) would

cause the damage of the pump seal, with

subsequent fuel leaks inside the burner.

The pump has a delivery pressure regulation

device (5). Pressure increases if turned in a

clockwise direction, and decreases if turned in

the other direction.

An indication of sensitivity is 1 bar per turn.

The pressure can be regulated in a range of

8 - 15 bar.

Do not loosen the knob (11) and periodically

check that it is firmly fixed, for safety reasons.

Loading...

Loading...