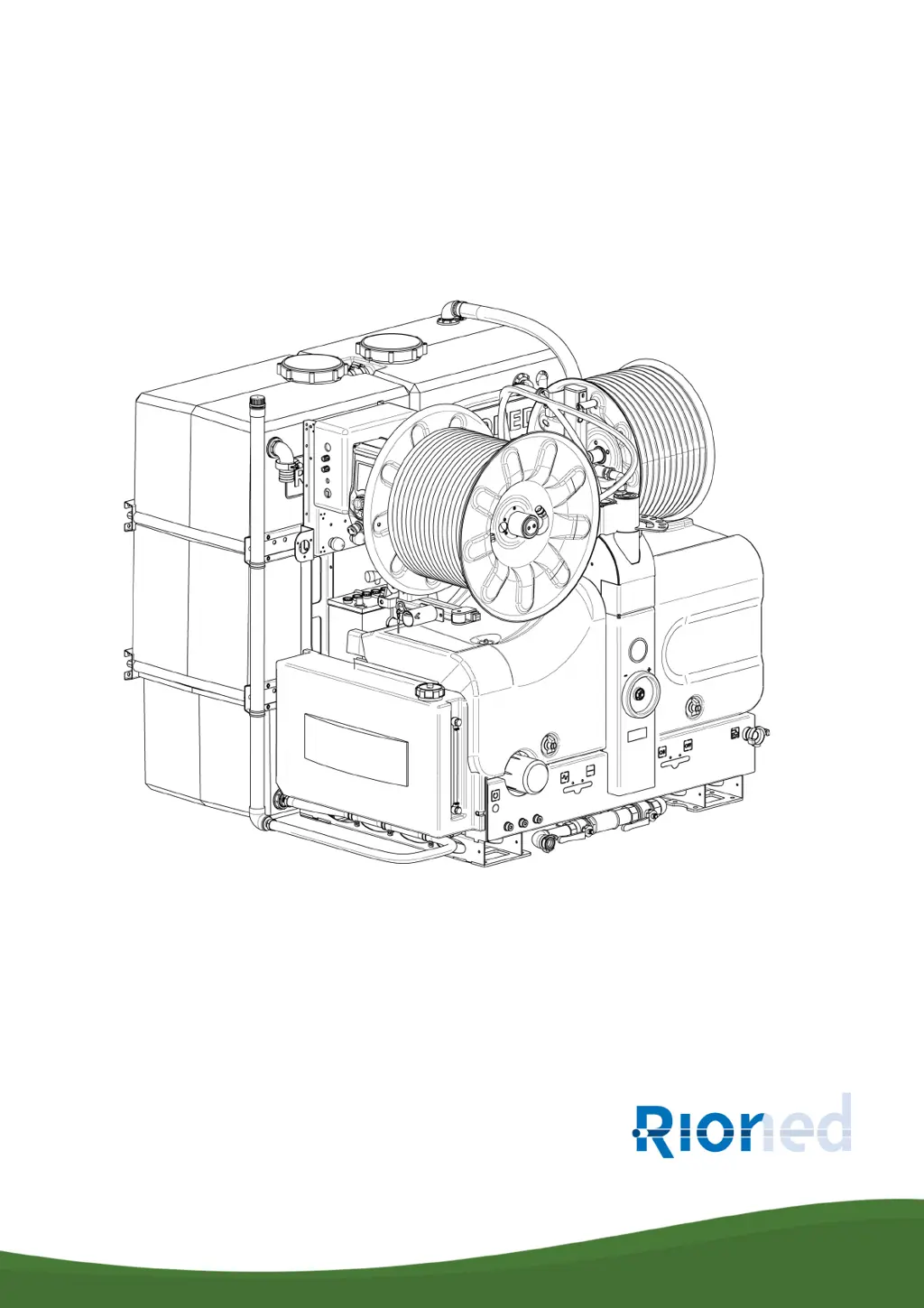

Why does my Rioned Pressure Washer engine will not start or stops suddenly?

- SsmithsarahAug 13, 2025

If the engine of your Rioned Pressure Washer won't start or suddenly stops, several factors could be at play. First, check if the fuel tank is empty and refill it if necessary. Also, inspect the main or accessory fuse; if blown, replace it, but contact Rioned if it blows again. Ensure the battery voltage isn't too low by charging or replacing the battery. Air in the fuel line can also cause this issue, so bleed the air at the engine. Verify that the Riomote control is switched on and repeat the procedure from the ‘Preparation for use’ section, and ensure its battery isn't flat, charging or replacing it as needed. Finally, check that the water tank isn't empty, refilling it if needed, and ensure the water and hydraulic oil temperatures aren't too high, allowing them to cool if necessary.