1952B OPERATION

Fill the canister with the desired amount of spray material. Reposition the sprayer on

canister top and snap clamp so it fits tightly. Check the switch to make sure it is “off”

before plugging into a 110/120 volt AC outlet. Once operating, the discharge rate of

the sprayer may be adjusted by turning the discharge control.

Spray Adjustment: The 1952B has an adjustment range of 1.5 to 5.3 gallons/hr. Spray

direction is variable through all degrees between 35 upward to 35 downward.

Wettable Powders: The 1952B sprays wettable powders at a maximum discharge

rate of 5.3 gallons/hr. Preliminary testing is recommended to insure that desired

rate is obtainable. Shake or agitate solution periodically to keep powders in suspen-

sion.

Spray Patterns: The 1952B atomizes 95% of its output of less than 50 microns.

Average particle size is 20 microns.

After Use: To store the 1952B or change spray materials, detach the sprayer from the

canister and turn it “on” to flush out any spray material. The sprayer should be emptied

of any unused spray solution and the canister should be washed after which the unit

should be reassembled. After use with wettable powders, detach the canister,

immerse the supply tube in clear water and flush until no residue can be seen in

the supply tube. Wash the canister thoroughly.

1026B OPERATION

Fill the canister with the desired amount of spray material. Reposition the sprayer on

the canister top and snap clamp it fits tightly. Check the spray selector valve on the

tube that extends from the motor housing to the tank cover plate and set it according

to the desired spray pattern. “Heavy” setting is achieved with valve lever turned full

left (counterclockwise.) This covers the valve opening and pressurizes the canister.

Heavy setting produces a dense wetting spray ideal for application of residual or

surface type spraying. “Fine” setting is achieved by turning valve lever full right (clock-

wise.) This opens the valve and allows air not utilized in spray discharge to escape.

Fine setting produces ultra fine particles ideal for flying insect control. Check the

switch to make sure it is “off” before plugging into a 110/120 Volt AC outlet for 1026B.

1026XB, 1026BG, 1026BR and 1026BP are wired for 220 volt. Once operating, the

discharge rate may be adjusted by turning the discharge control at end of hose.

Spray Adjustment: The “fine” (unpressurized) setting has an adjustment rate of 1.5

to 3.5 gallons/hr. On “heavy” pressurized setting, the adjustment rate is 6 to 14

gallons/hr. Spray direction is variable through manipulation of the discharge hose.

Wettable Powders: Preliminary testing is recommended to insure that desired rate is

obtainable. Shake or agitate solution periodically to keep powders in suspension.

After Use: When the unit is turned “off” after spraying, siphoning action may continue

for a moment, resulting in a solid stream of spray material. To prevent this, tip the

nozzle up straight as you switch “off” the motor thus flushing spray solution remaining

in the discharge line back into canister. To store the 1952B or change spray materials,

detach the sprayer from the canister and turn it “on” to flush out any spray material. The

sprayer should be emptied of any unused spray solution and the canister should be

washed after which the unit should be reassembled. After use with wettable powders,

detach the canister, immerse the supply tube in clear water and flush until no residue

can be seen in the supply tube. Wash the canister thoroughly.

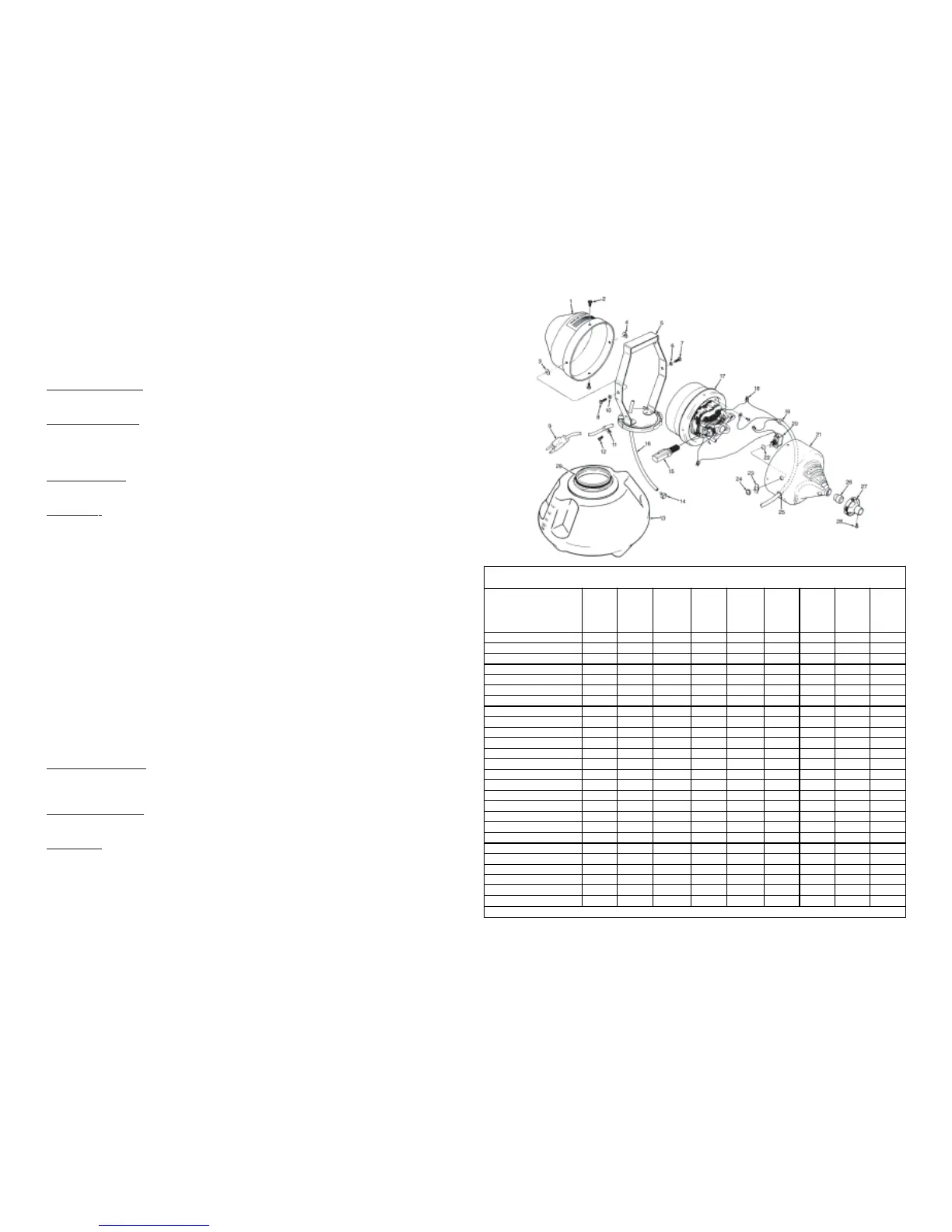

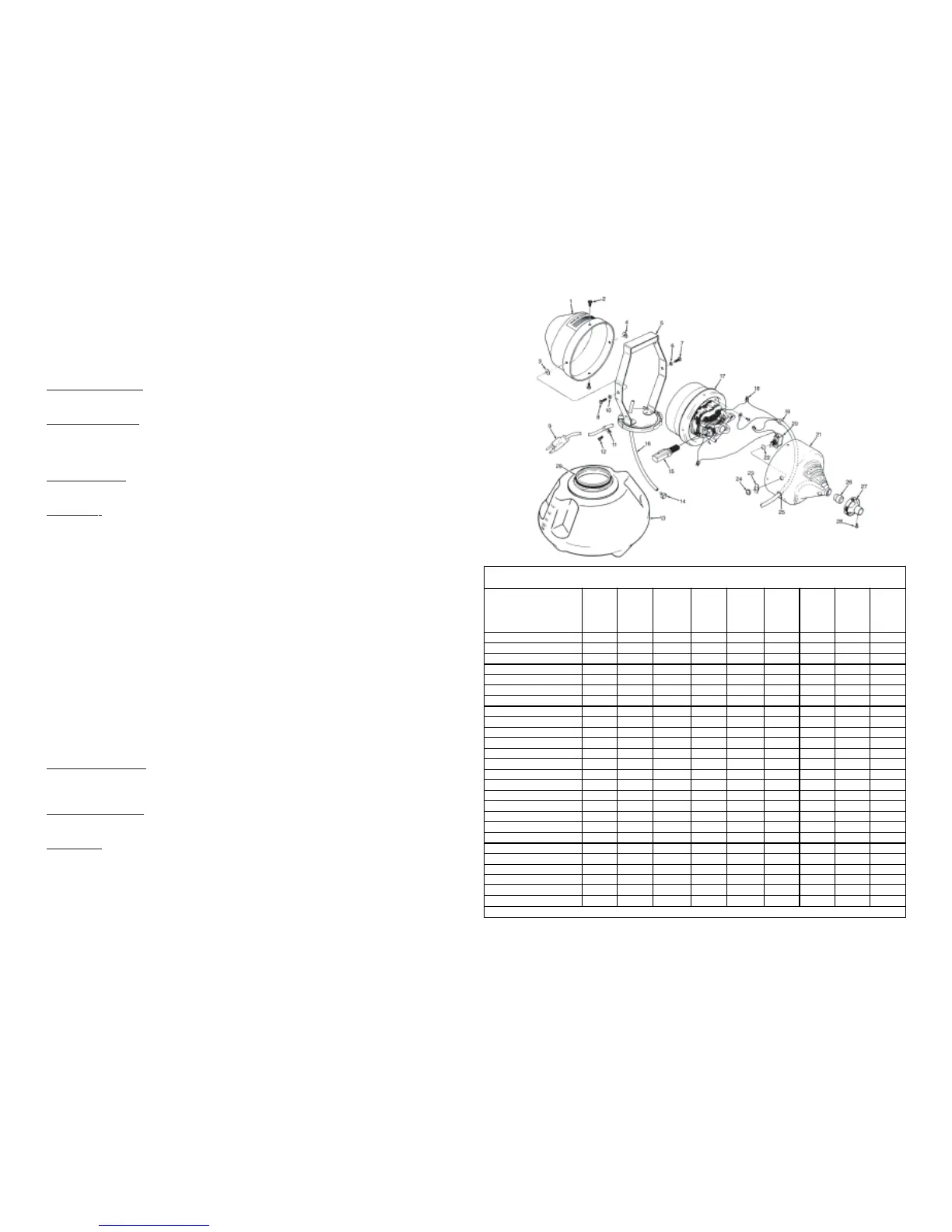

Parts List for Model 1952B

Figure Number

Description

Outlet

Kit

946-705

Switch

Kit

944-825

Motor Kit

944-850

Cord kit

(120V)

944-820

Mototr

Euro Kit

CE

944-786

Cord kit

(Euro)

948-306

Motor

Euro Kit

944-785

Frame

Kit

944-600

Misc

Parts

1. Intake Housing *

2. Screw # 10 - 9/16 * *

3 & 4. Spring Washer * *

5. Frame *

6 & 10 Shoulder bushing * *

7 & 8 Screw # 10 - 3/4 * *

9. Cord 22 inch 3 m

11. Cord Clamp * * *

12. Clamp Screw # 8 * * *

13. Canister 952-552

14. Intake Strainer *

15. Brush ** 953-500

16. Supply Tube *

17. Motor 120V 220V 220V

18. Wire Connectors * * * * *

19. Cord Stop * * *

20. Switch *

21. Outlet Housing *

22. Lock Nut *

23. Switch On/Off plate *

24. Switch Plate Nut *

25. Grommet ** * * *

26. Nozzle (Brass) *

27. Adjustment Hub *

28. Hub Screw # 4 - 1/4 *

29. Gasket 805-202

** Denotes 2 each are required

Loading...

Loading...