4. Disconnect the positive cable from the battery. Attach the

cable labeled “BATTERY POST” to the positive terminal on the

battery.

Note: If a stop light switch or other accessory must be

energized while towing, make sure to connect the accessory

to the positive side of the battery. DO NOT CONNECT ANY

ACCESSORIES TO THE SOLENOID.

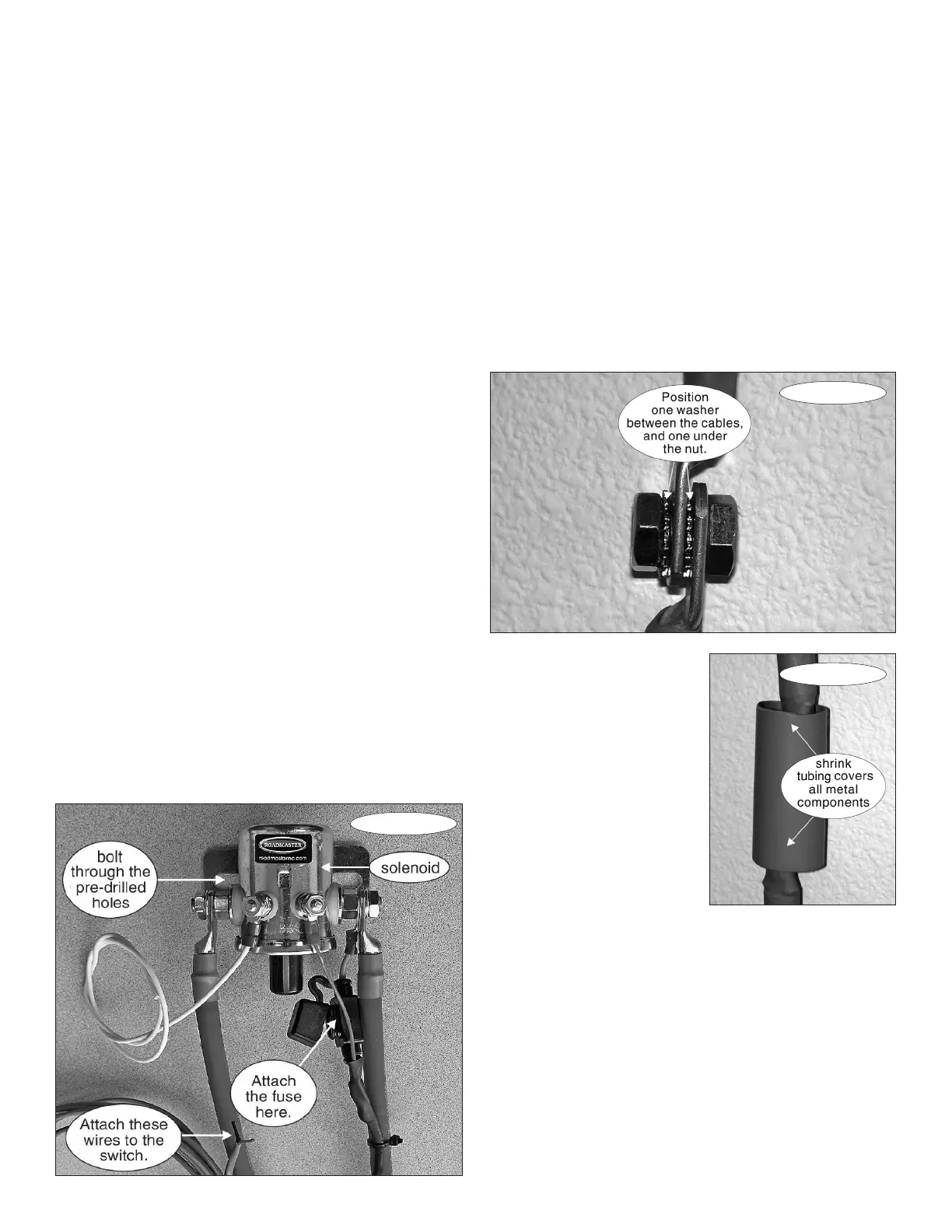

5. Slide the provided section of shrink tubing (Figure 2) over

the cable labeled “POSITIVE CABLE.” Then attach this cable

to the positive cable you just removed from the battery: align the

two ends of the cables so they match. Connect the two cables

together as shown in Figure 2.

Note: It is imperative that the star washers are positioned

as shown.

Note: If the end of the vehicle’s battery cable has a diameter

smaller than 5/16", use a 5/16" drill to enlarge it.

Figure 1

continued from preceding page

Installation

1. Follow the vehicle manufacturer’s instructions to disconnect

the negative battery cable.

2. Choose a mounting location for the solenoid (Figure 1)

inside the engine compartment. This mounting location must

meet the following conditions:

• The mounting point must have a surface of sufficient

strength to hold the solenoid firmly in place.

• There are two cables attached to the solenoid. The end

of the cable labeled “BATTERY POST” must be within reach

of the vehicle’s positive battery post.

• The solenoid will be attached with the two included bolts

and nuts. Make certain that the bolts will not damage any com-

ponents on the other side.

• The solenoid must be grounded by using the provided

white ground wire. Make certain a good ground is available

within two feet of the solenoid.

• The solenoid must be mounted in a location where it is

protected from direct road spray.

• The black tip of the solenoid MUST be pointed downward.

3. Position the solenoid at the mounting location you have

chosen. Drill two ¼" holes for the bolts through the pre-drilled

holes (Figure 1) and attach the solenoid.

Also attach the white ground wire to any good chassis

ground with the included ring terminal and self-tapping screw.

If the cables must be rotated on the solenoid post, then

FOLLOW THESE INSTRUCTIONS CAREFULLY! Put a

wrench on the inside nut and use it to hold the inside nut in

position. Now, loosen the outside nut with a wrench, reposi-

tion the cable and retighten while carefully holding the inside

nut in position. Rotating the inside nut WILL CAUSE NON-

WARRANTY FAILURE of the solenoid.

CAUTION

You WILL destroy the solenoid unless you hold the in-

side nut stationary and ONLY rotate the outside nut. This

damage will not be covered by warranty.

Figure 3

Figure 2

6. Slide the shrink tubing

over the connection as shown

in Figure 3. Be certain no metal

is exposed. Seal the shrink tub-

ing with a heat gun or similar

device.

CAUTION

Make certain that no metal

is exposed on either side of

the shrink tubing. If metal is

exposed, a short circuit may

cause an electrical fire, which

may result in severe damage

to the vehicle.

7. Attach the provided protective loom to both cables.

CAUTION

In order to prevent damage from a short circuit,

cover both cables with the included protective loom. If the

cables are not covered, a short circuit may cause an electri-

cal fire, which may result in severe damage to the vehicle.

Note: Roadmaster recommends using an anti-corrosion

battery terminal spray on all exposed connections.

continued on next page

Loading...

Loading...