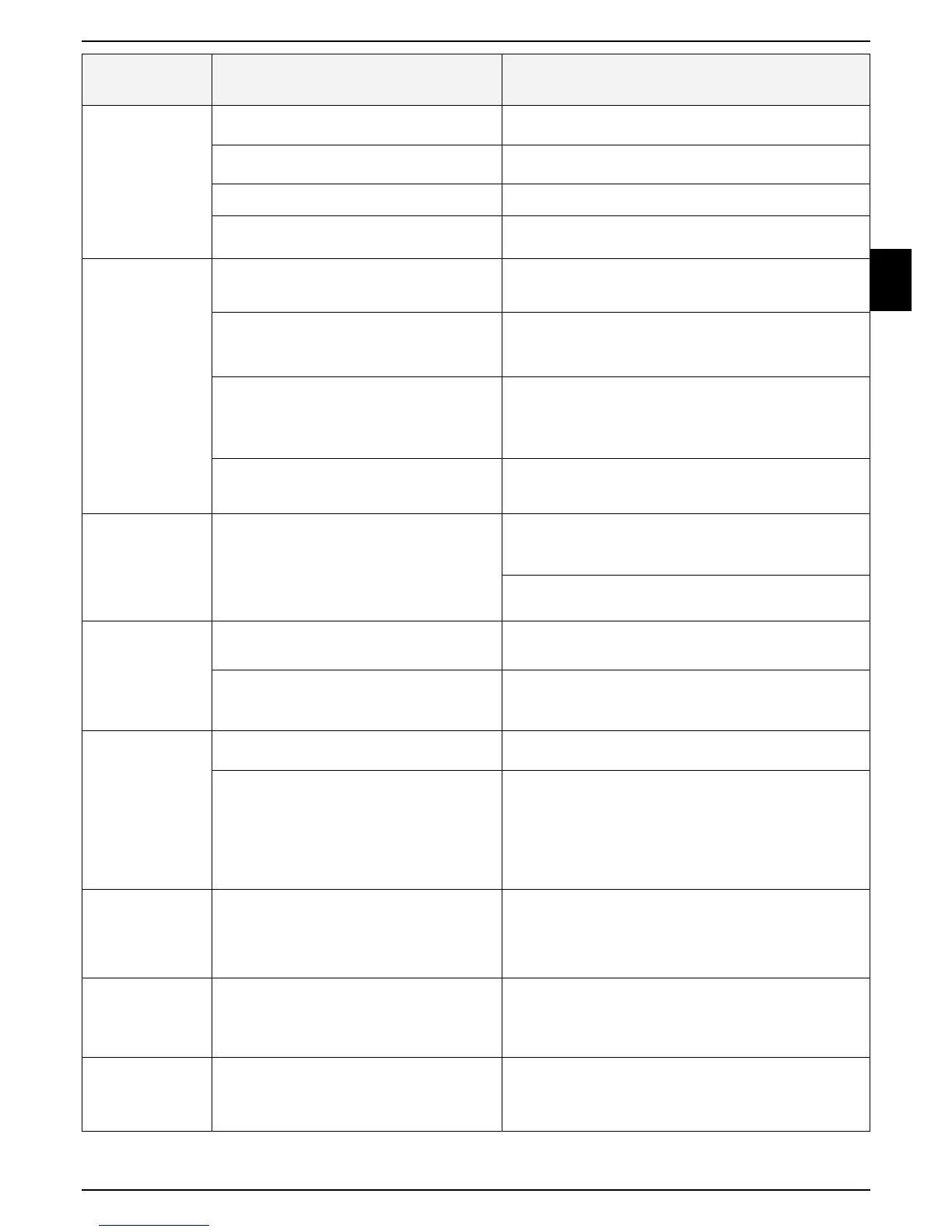

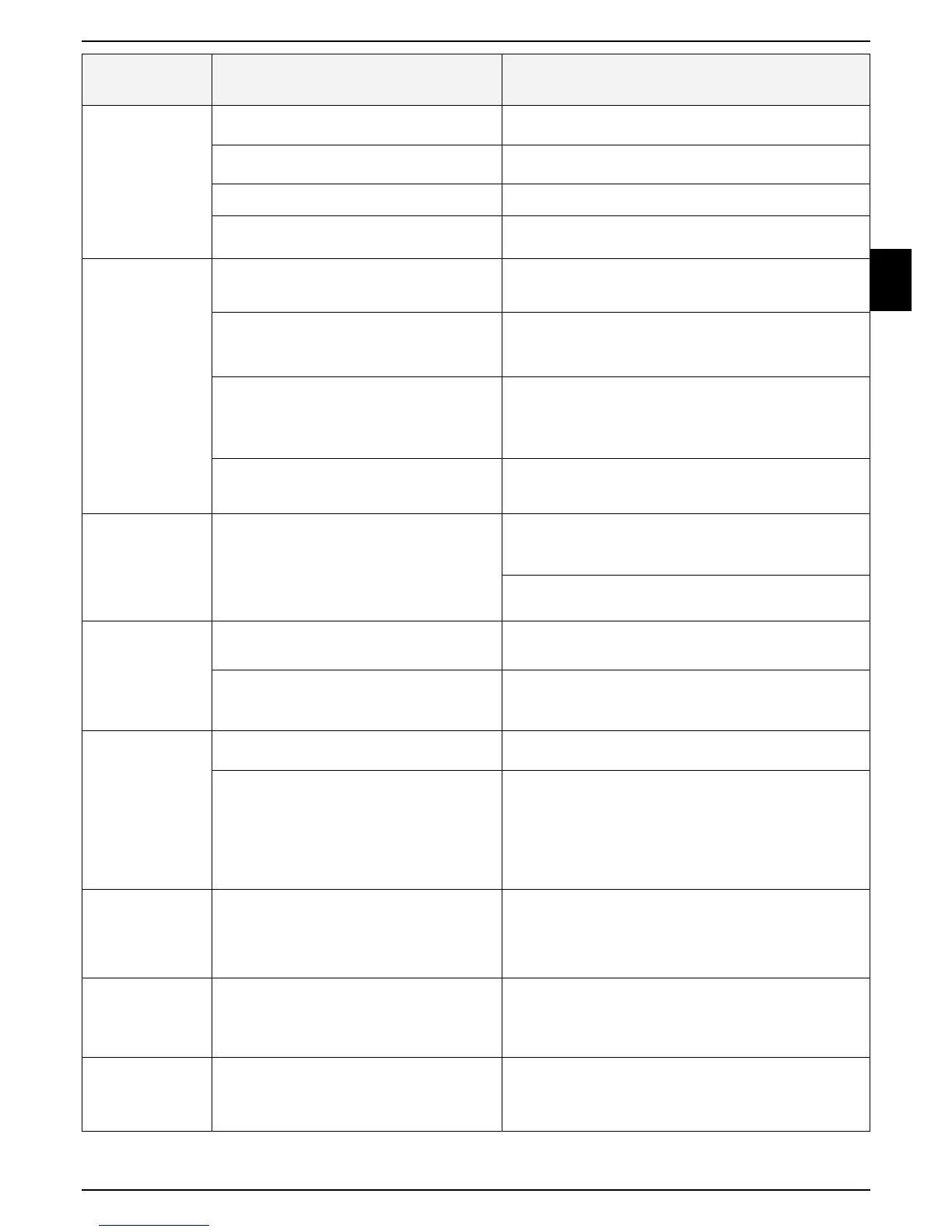

Problem

Encountered

Probable Cause/Event Corrective/User Action

Mower does not

dock properly and

sometimes miss

the Base Station

contacts

- Height differences between the lawn and the

Base Station surface.

- Fill some ground to flat the lawn with the Base Station to

allow smooth entrance to the station.

- Wire underneath the Base Station is not tight

and placed in the middle of the Station.

- Confirm the wire underneath the Base Station is straight

tighten and centered below the Base Station.

- Base Station is setup on a side slope. - Move the Base Station to a relatively level ground.

- A base station is placed too close to the

corner of the lawn

- Move the Base Station within 3 meters from a corner.

Uneven mowing

results

- Robomow does not complete mowing at the

min. time, due to inactive time during the

Mowing Cycle.

- Minimize the Inactive Time windows to allow Robomow

to complete the Mowing Cycle faster and to achieve even

mowing result.

- Grass is growing very fast.

- If it is the fast growing season - reduce the time between

mowing cycles (refer to Section 4.3.2 Increase /

Decrease Operations).

- Lawn shape is complicated shape, Narrow

Passages, obstacle and islands).

- In complicated lawn the mower takes more time on the

lawn to achieve better mowing results.

Increase the Intensity (refer to Section 4.3.2.1 Increase /

Decrease Operations).

- The mowed area is smaller than the actual

lawn area.

- Increase the zone area (refer to Section 4.3.3 Edit an

existing Zone).

Robomow

operates at the

wrong time.

- The Inactive Time data (days and Hours) is

incorrect.

- Verify that the time in the mower is set correctly.

- Set the time (refer to Section 4.4.4 Time and Date).

- Reset the Inactive Time (refer to Section 4.3.1 Set

Inactive Operating Time(s)).

Cut wire indicator

is flashing on

Power Box

- Cable is disconnected or damaged between

Power Box and the Base Station.

- Confirm cable is plugged in and wire leads are firmly

attached.

- Perimeter Wire is cut.

- Walk along Perimeter Wire.

Look for cuts or breaks in the wire.

Repair with Robomow wire splice connectors.

Poor connection

indicator is

flashing on Power

Box

- Poor connections - Check and repair all loose/poor or corroded connections.

- Twisted cables, or a screw terminal,

insulated with insulation tape is not a

satisfactory splice.

Soil moisture causes the conductors to

oxidize and after a while. This results in

broken circuit.

- Use the connectors supplied in the box. They are

waterproof and give a reliable electrical connection.

Robomow

is noisy and

vibrates

- Damaged or unbalanced blade

- Check if the lawn is free from branches, stones or other

objects that can damage the blade before operating the

Robomow.

- Replace the blade

LCD display

is in a foreign

language.

- The language setting was changed or not

correctly set.

- Press the CANCEL + DOWN buttons for more than 3

seconds. This is a shortcut to the Language menu.

Change the language.

Mowing or

charging times

are shorter than

usual.

- This behavior is normal at low temperatures

(below 15 ºC (59 ºF)).

- No action is required.

Loading...

Loading...