BA_D8755

Issue 03/2004

Subject to changes without notice.

Page 2/2

Any mounting position of the check valves

is possible.

! Return the leakage return port L

depressurised at the reservoir.

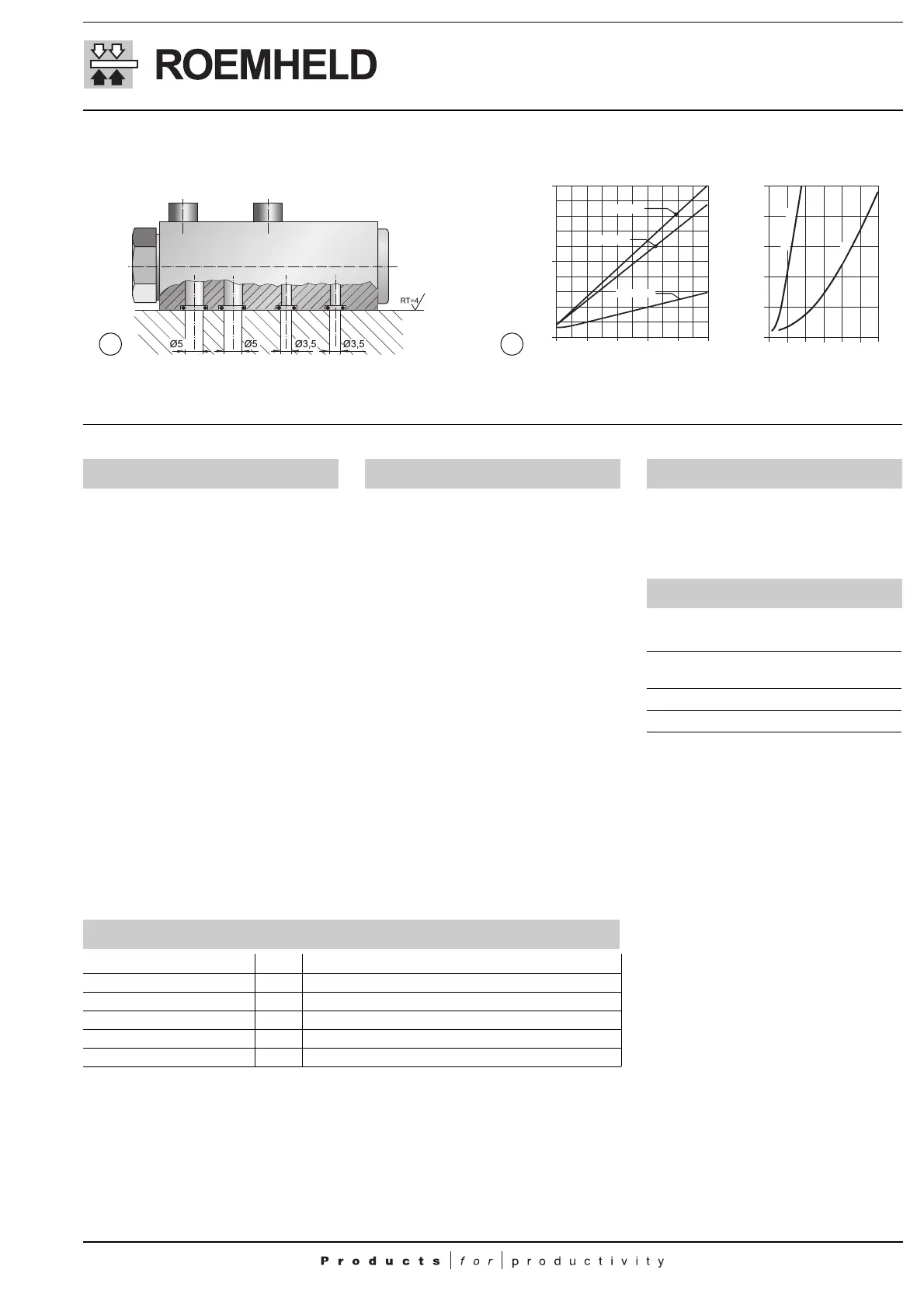

Type 2951-416 (for manifold-mounting)

! Drill holes for hydraulic oil supply and

return in the fixture.

! Grind flange surface.

! Clean the support surfaces.

! Fasten the valve with O-rings on the

fixture.

Provide the threads in the fixture.

! Connect hydraulic lines to qualifying

standards, pay attention to scrupulous

cleanness! See also Römheld data

sheets A0.100, F9.300, F9.310 and

F9.360.

! Use only fittings "screwed plug B" as

per DIN 3852 (ISO 1179).

! Do not use sealing tape, copper rings or

coned fittings.

! Check sealing of the hydraulic

connections!

Check if the hydraulic ports are tight

(visual control). The valve itself is

maintenance free.

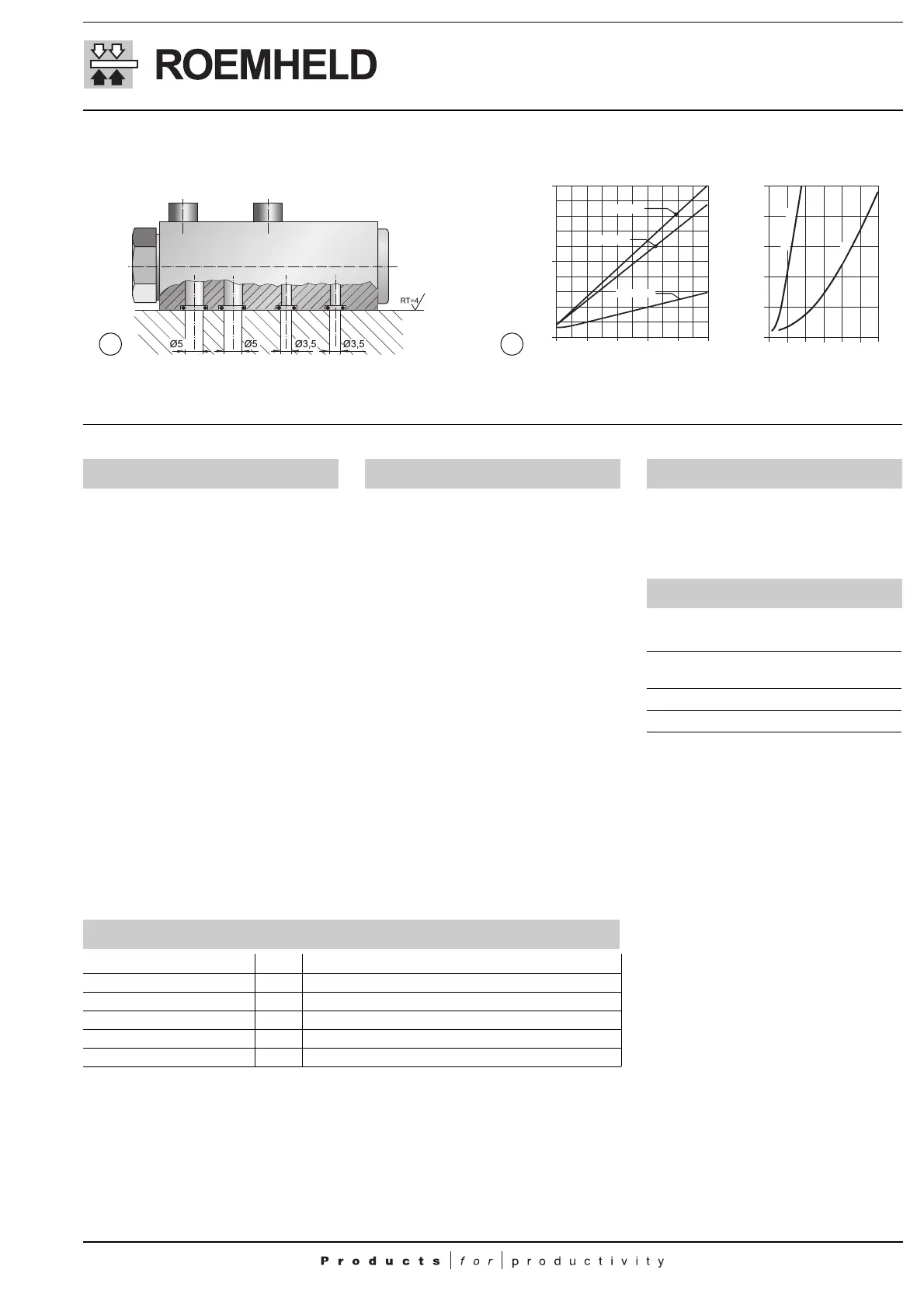

100

200

0

100

200

300

400

500

0

2951-501

2951-417

2951-421

0

2

4

6

8

10

1002030405060

2951-417

2951-501

All figures are schematic figures.

1 2

Control pressure p

Z

for unlocking at

(p

B

= 0 bar)

∆p-Q-curves only valid for flow

from B → A and for unlocked return

line A → B

Flow resistance ∆p

[bar]

Flow rate Q [l/min]

Control pressure p

Z

[bar]

p

A

[bar]

Installation Hydraulic connection

General characteristics

Part-no. 2951-416 2951-417 2951-421 2951-501

Port A, B Ø 5 G1/4 G1/2 G1/2

Control port Z Ø 3.5 G1/4 G1/4 G1/4

Control pressure p

Z

≥ bar 0.3 p

A

+ 12 0.32 p

A

+ 12 0.12 p

A

+7 0.38 p

A

+ 12

Max. operating pressure bar 500 500 500 500

Max. flow rate l/min 20 15 55 55

Maintenance

Data sheets

Types Corresponding data sheets

2951-417,

2951-501

C2.9511

2951-416

C2.9512

2951-421

D8.755

Loading...

Loading...