Roger Technology Swing Gate Brushless B70-2DCHP Control Panel

Quick Start Guide Extended Mode

3

STEP 4)

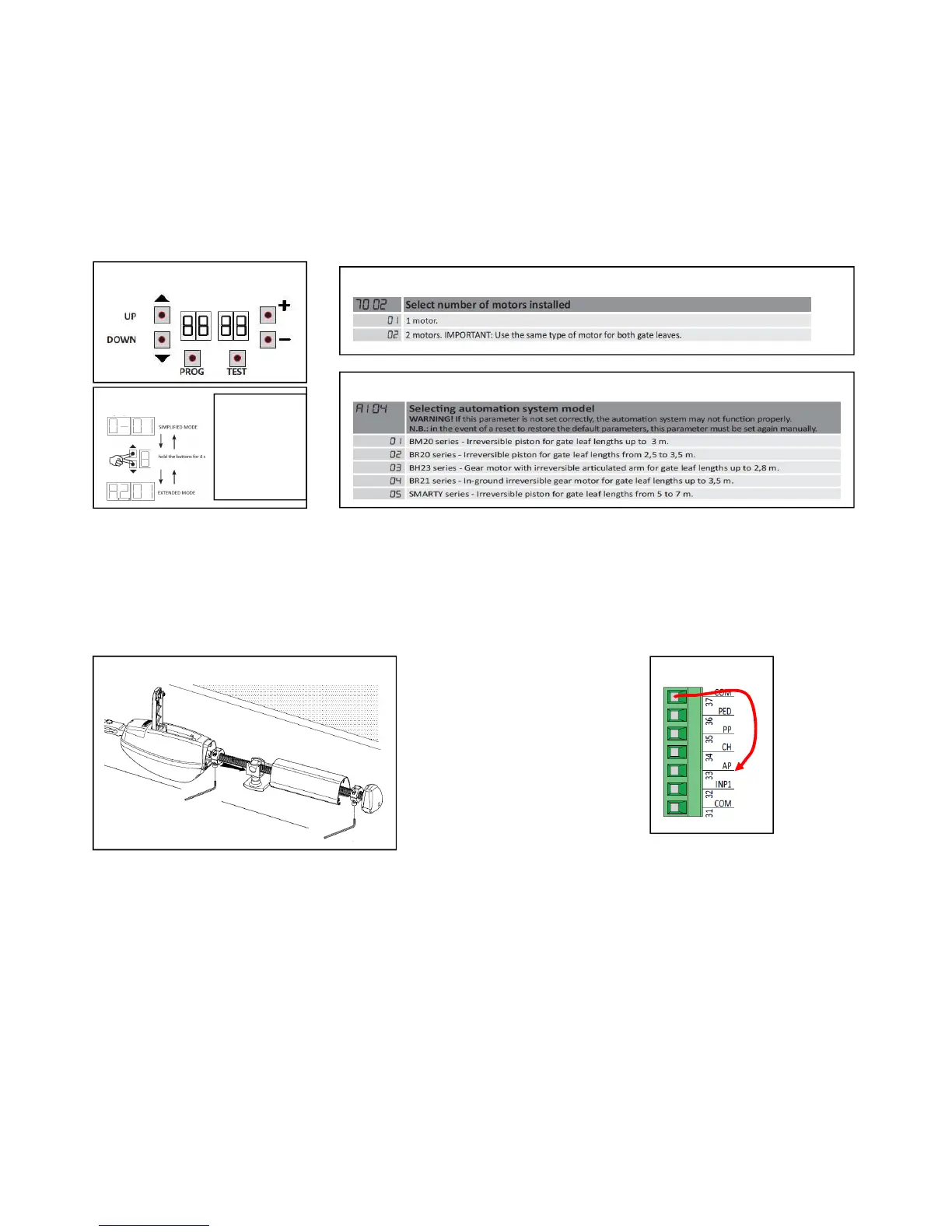

Using the control panel buttons UP/DOWN, Fig.7 Scroll down to menu 70 Fig.8 and select 1 motor or 2 motors.

Change the parameter using the + - buttons. After a few seconds the board will realise the change automatically.

From the chart in Fig.9, scroll down to A1 , select the correct parameter for the motor you have connected using the

+ - buttons, make sure the panel realises the change. It should do this again automatically after a few seconds of the

change.

(See Fig7b for B70-2DC with dual menu)

Step 5)

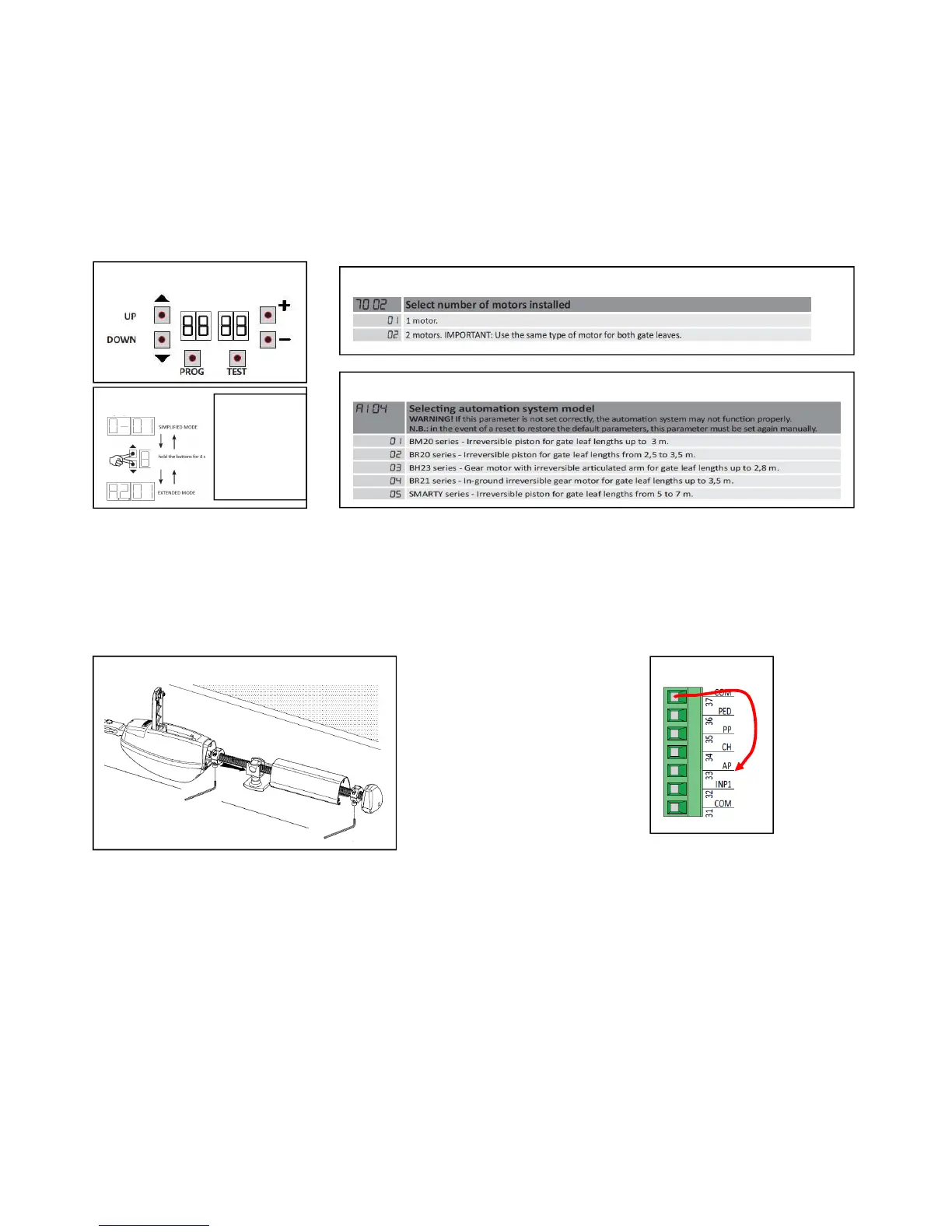

Using a hex key tool, and the unlock lever, set the maximum open and closed stop positions of the motor, to give the

correct corresponding gate open and closed positions for each gate as shown in Fig.10. Double check the positions

of the collars by swinging the gate open/closed with the motor unlocked.

Step

Step 6)

You should now be ready to carry out the stroke programming sequence. But first you should check that the motors

are traveling in the correct direction in relation to the control panel. To do this it will be necessary to give the panel a

brief open or close command and compare the command to the movement of the gate direction, but then quickly

turn off the power once you realise the movement. Attach a temporary cable to COM as FIG.11 then, briefly touch

the other end into the AP terminal. The AP terminal is the open command, so the gates should open. Turn off the

power to the panel as soon as you see the movement. If the gates close with the AP input, the gates are going the

wrong way. It will be necessary to swap around any two wires to the incorrect motor (ZYX) as detailed in Fig.2.

Loading...

Loading...