Operation of Quick Release Mechanisms

IMPORTANT: IF YOU DO NOT UNDERSTAND ANY PORTION OF THESE INSTRUCTIONS,

HAVE YOUR ROLF PRIMA DEALER SHOW YOU PROPER INSTALLA-

TION OR CONTACT ROLF PRIMA DIRECTLY.

1. Check both wheels before every ride.

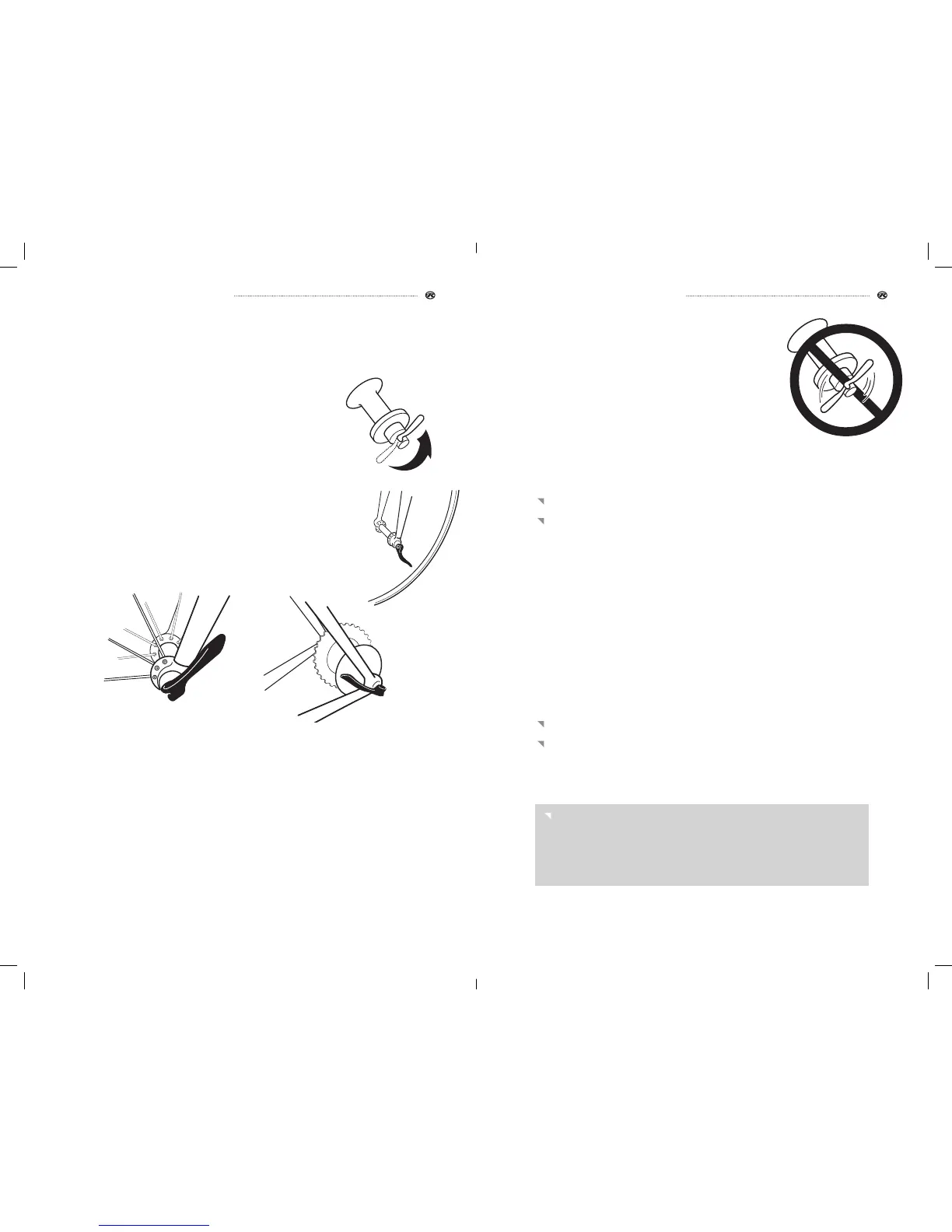

2. Move the quick release lever to the OPEN position and set the

wheel so it seats firmly in the frame or fork tips [figure 1].

3. With the lever about halfway between the OPEN and CLOSED

position [fig. 2], tighten the quick release adjusting nut on the

opposite end of the quick release axle until finger tight, ensuring that

the nut is threaded on a minimum of 5 turns.

4. Place the quick release lever in the palm of your hand and move the

lever fully into the CLOSED position. [figure 3 for front wheels, figure

4 for rear wheels]. At the halfway closed position you should feel

resistance to this motion.

5. If the quick release lever can be moved to the CLOSED position with little or no

resistance, clamping strength is insufficient. Return the lever to the OPEN position

and tighten the nut further. Close the lever, testing again for resistance. When the

quick release mechanism is properly tightened and clamped in the closed position, the

clamping force will be adequate to cause metal into metal engagement [embossing] of

the fork or frame tips. It should require effort to close the Quick Release, yet it should

not be difficult.

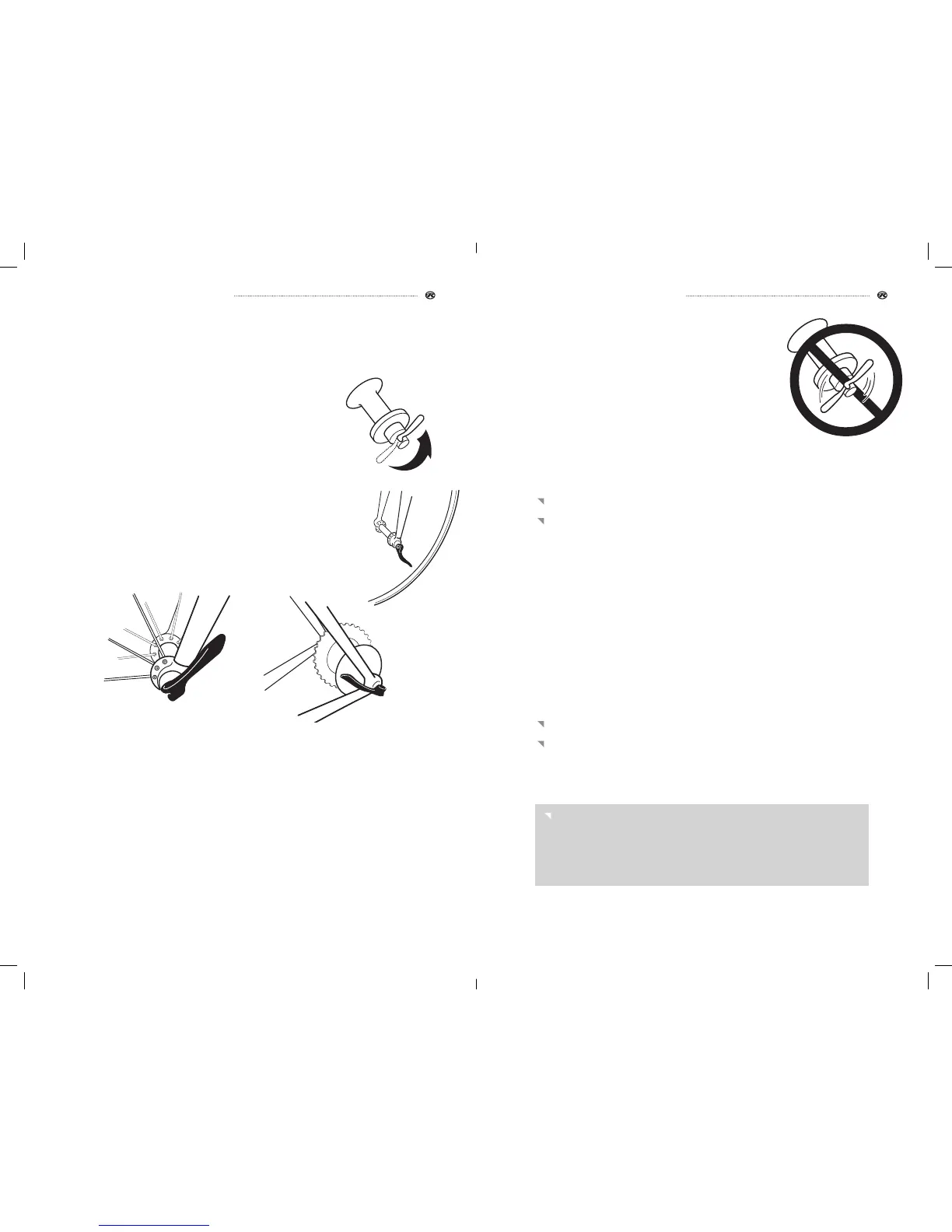

DO NOT TIGHTEN THE QUICK RELEASE MECHANISM BY USING THE QUICK

RELEASE LEVER LIKE A WING NUT [FIG 5]. OVER-TIGHTENING THE QUICK RELEASE

MECHANISM MAY CAUSE DAMAGE TO THE QUICK RELEASE ASSEMBLY.

6. Perform these two tests to ensure that the quick release

mechanisms are properly closed:

A. Lift the front of the bicycle and give the top of the tire

a sharp downward blow with a closed fist. The wheel

should not come out of the fork, be loose, or move

from side to side. Repeat this test to the rear wheel. If

uncertain, repeat the tightening process, as shown in

steps 2-6, above.

B. With the quick release lever properly adjusted and closed,

it will not be possible to rotate the quick release lever in a circular motion parallel to

the wheel as pictured in figure 5.

Inspection – Weekly

Check that there are no loose, damaged, or broken spokes

Check that there are no cracks in front or rear rims

As alloy rims near the end of their fatigue life, cracks may develop. If cracks are found, do not ride

the wheel. Take the wheel to your Rolf Prima dealer or contact Rolf Prima for service.

Carbon fiber rims may become damaged as a result of an accident, impact, or improper handling.

Damage to carbon fiber components may be contained internally, and the rims may appear

outwardly normal and undamaged at a glance. It is very important to thoroughly inspect all the parts

on your bicycle after an accident – but it is especially important that you thoroughly inspect your

carbon fiber rims for signs of damage. Look closely for cracks, deep scratches or gouges, delamina-

tion, loose fibers and other surface flaws. If you suspect the rim has been damaged, take your wheel

to your Rolf Prima dealer for further inspection.

Inspection – Monthly

Check that there is no excessive looseness in hub bearings in both wheels

Check both rims for wear

Bicycle rims will wear from the friction of rim braking and may eventually require replace-

ment. Inspect the rim sidewalls and braking surfaces for heavy grooving or cracks.

WARNING!

Inspect your wheels regularly. Make sure your Quick Release mechanisms are

closed properly before each ride. Worn or damaged components, or improperly

closed Quick Release mechanisms can cause an accident which may result in

serious injury or death.

CLOSED

OPEN

OPEN

CLOSED

FIGURE 1

FIGURE 2

FIGURE 3

FIGURE 4

FIGURE 5

Loading...

Loading...