Approved meter oil: High VI R&O AW ISO VG 15

red, is available from Romet in one quart (litre)

plastic bottles. Other approved oil: Shell Morlina S2

BL 10. Use only one type of oil (never mix different

oils together). The addition of oil additives will

change oil properties which may cause the meter to

read incorrectly or result in complete meter failure.

➢ Ensure all oil plugs (and any other connections) are

properly tightened and secured before pressurizing

the meter set.

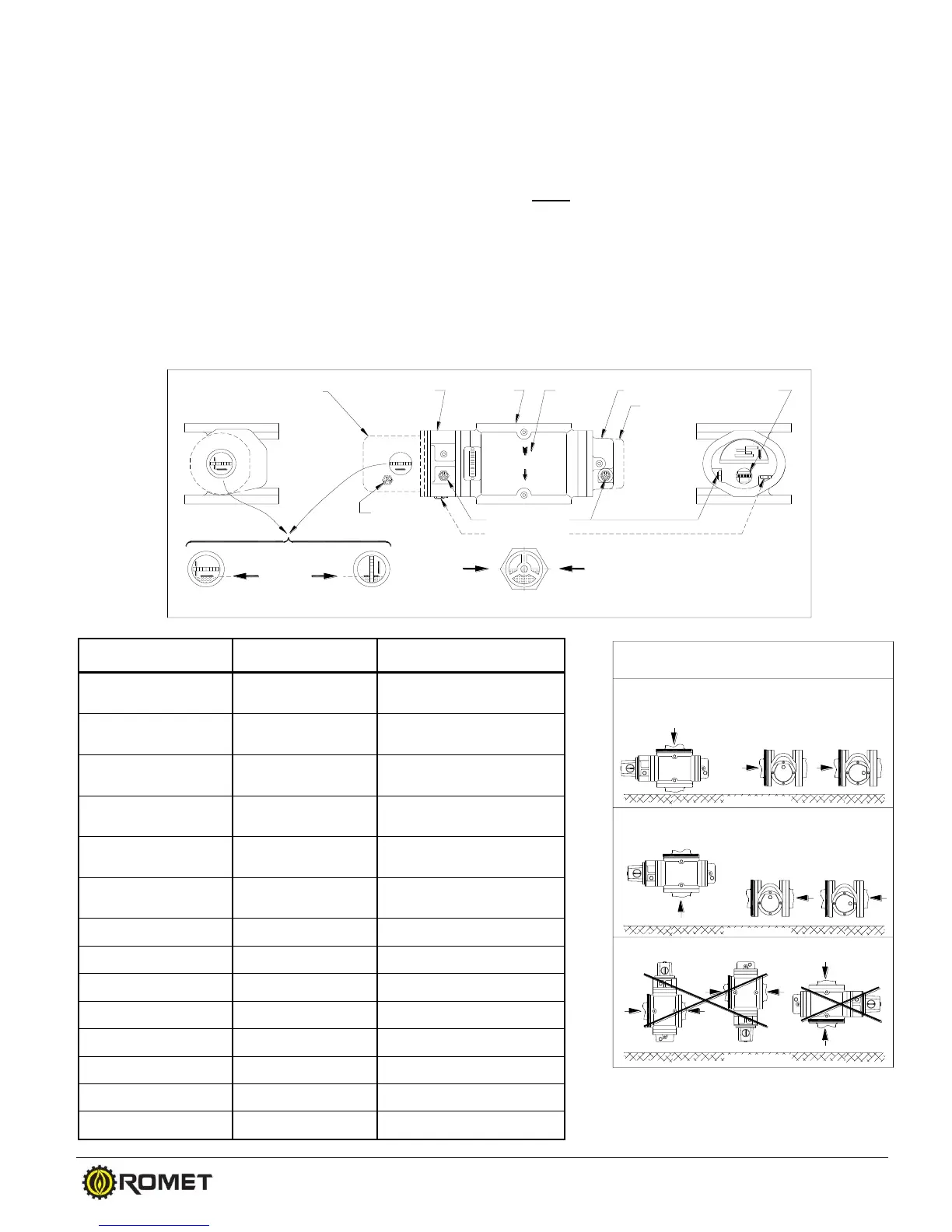

➢ When the meter installation has been completed,

the meter set should be pressurized SLOWLY

(maximum 5 psig or 35 kPa per second) up to the

allowable operating pressure specified to avoid

internal over-speed or slamming of the meter.

Should the installation be subject to sudden

“INSTANT ON-OFF” loads, a properly sized

restricting orifice or venturi flow nozzle should be

installed downstream of the meter to protect the

meter from damage.

➢ Check for any gas leaks or other possible problems.

➢ After start up, the readout counter or drive should

be running smoothly and in the correct direction

when the required gas flow condition has been

reached.

➢ Note: For further information, refer to Romet

“Installation & Maintenance” RM or G series

booklets. Since this publication is a general

guide, always refer to your company’s standard

practices for other details. This Bulletin is based on

actual field problems encountered and gas industry

standards.

Warning: Tampering or modifying design of

product may cause a potentially

hazardous situation.

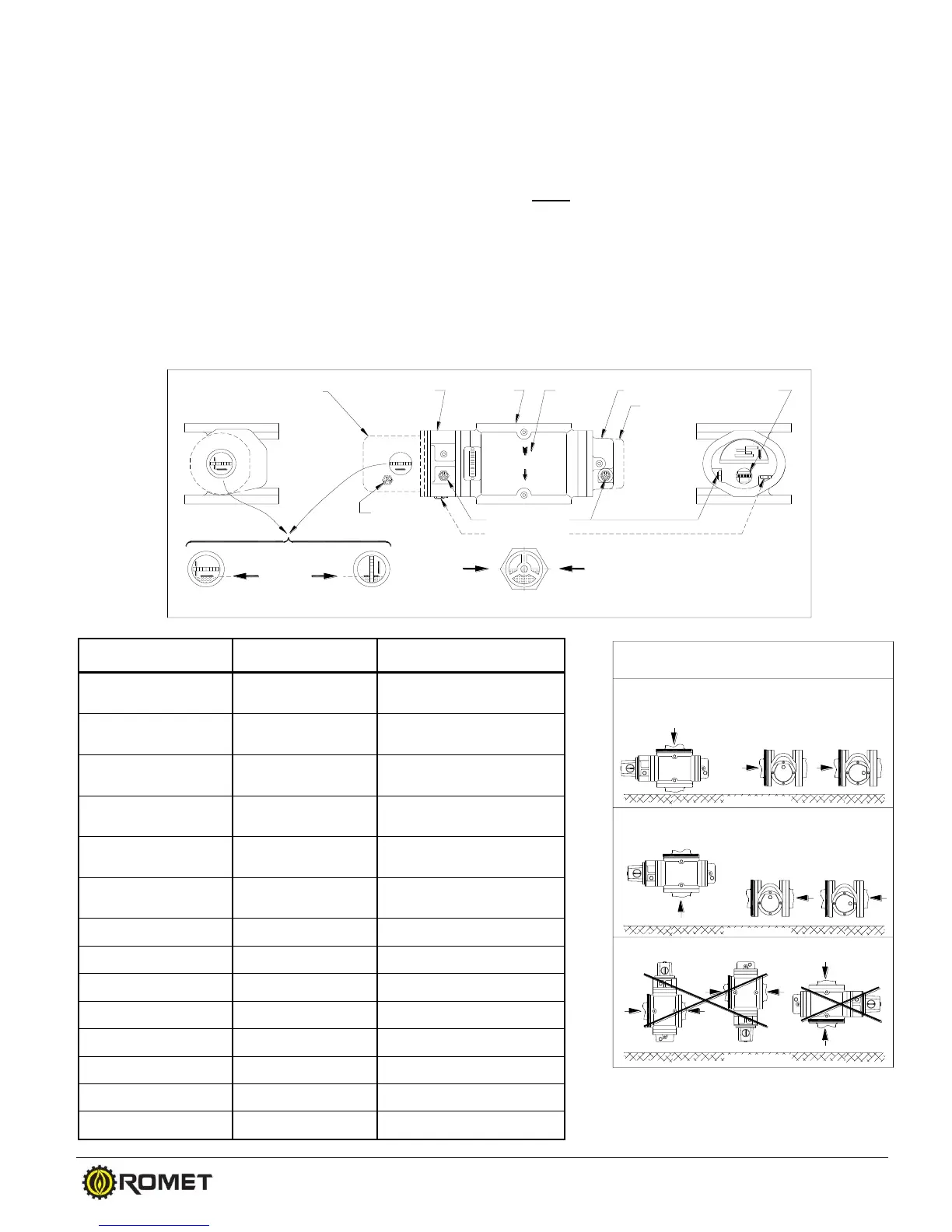

TABLE 1 HARDWARE SPECIFICATION TABLE

Loading...

Loading...