10

Operating instructions G series UTD.187.2019.09.00_EN

UTD.187.2019.09.00_EN Operating instructions G series

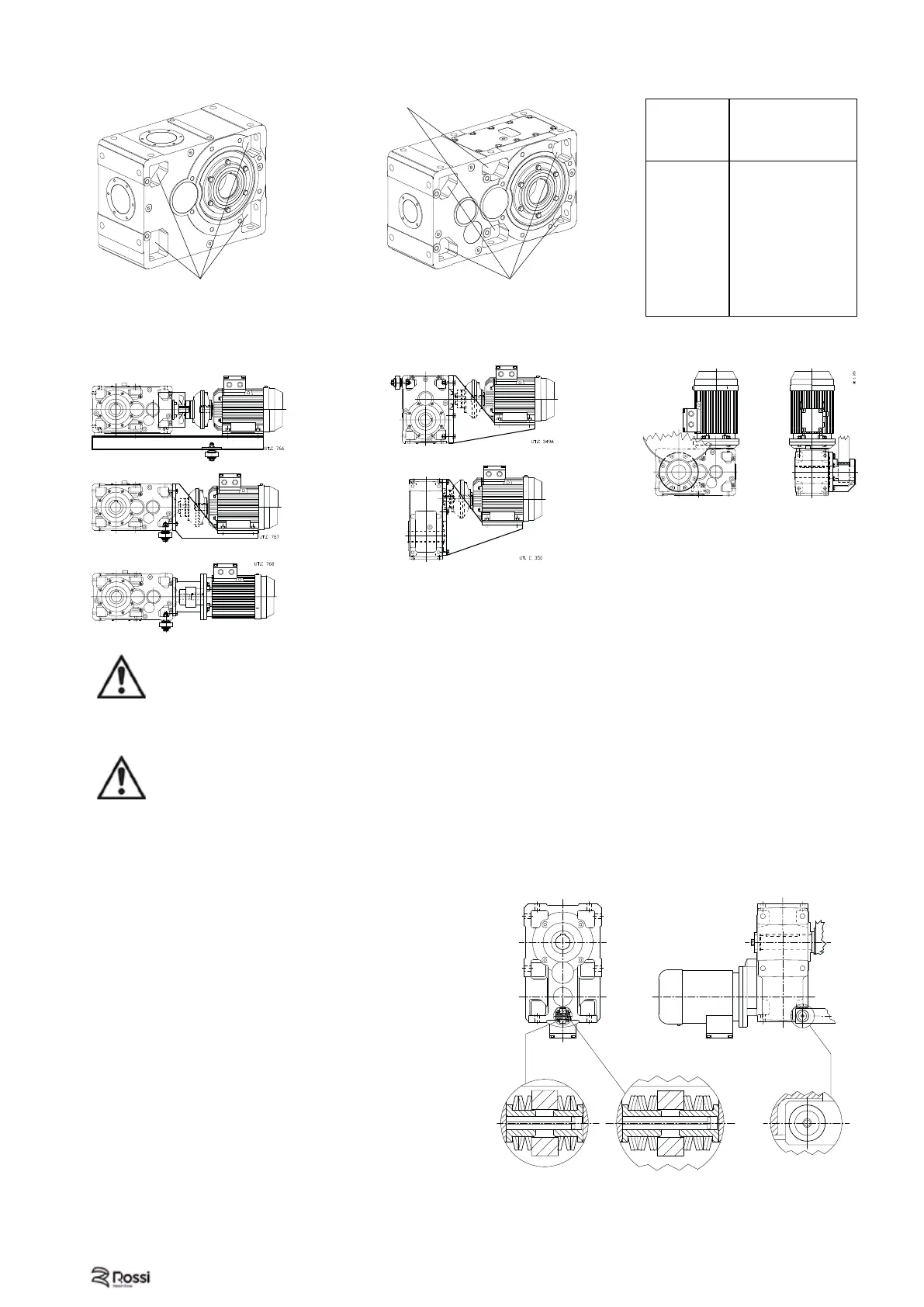

Nut seating

Bolt or nut seating

(maximum length stated in the table)

Bolt or nut seating

(maximum length stated in the table)

•

•

•

•

•

•

•

•

•

•

5.4 - Foot mounting

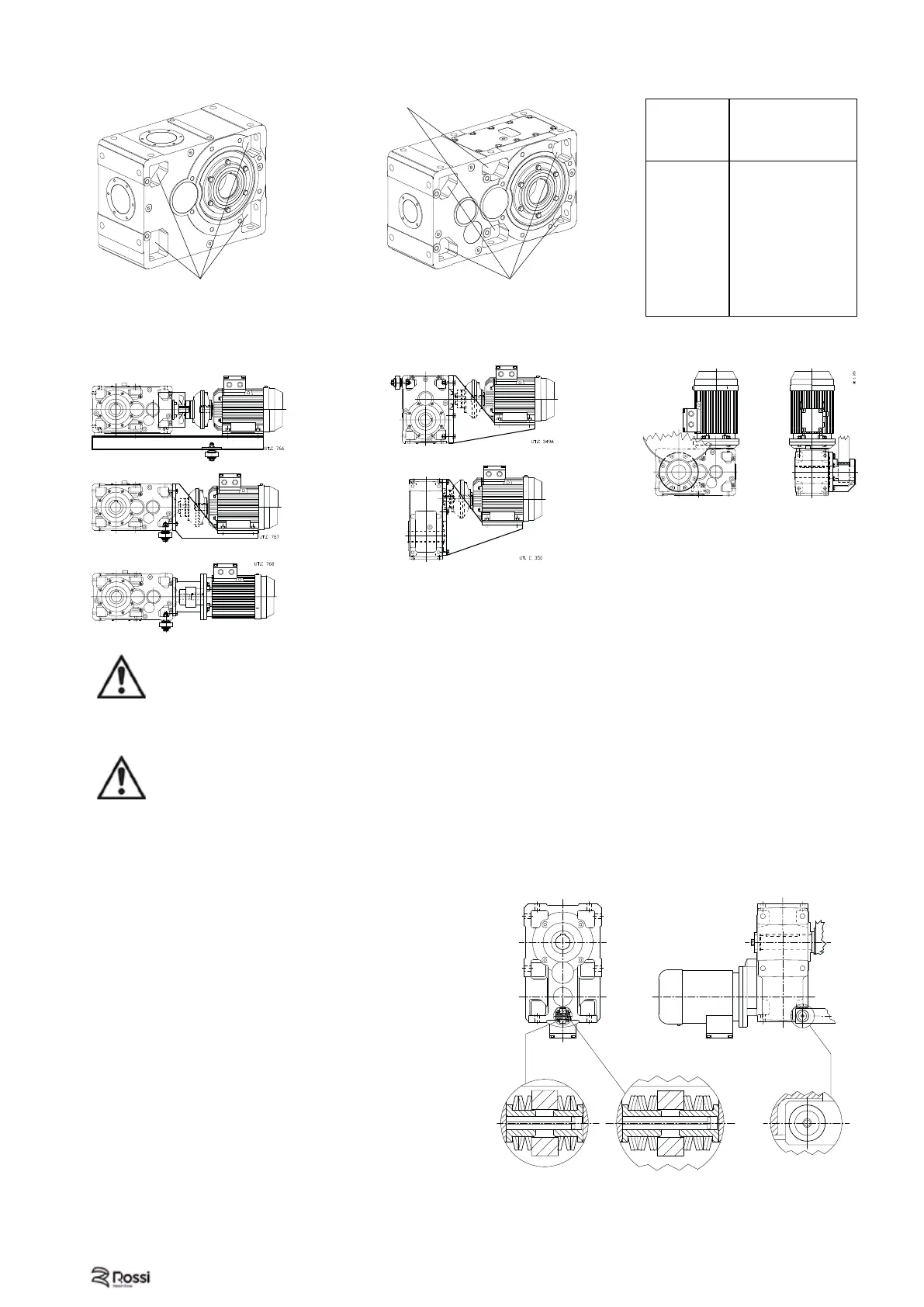

5.5 - Shaft mounting

Important! When shaft mounted, the gear reducer must be supported both axially and radially (also

for mounting position B3 ... B8) by the machine shaft end, as well as anchored against rotation only,

by means of a reaction having freedom of axial movement and suffi cient clearance in its couplings

to permit minor oscillations always in evidence without provoking dangerous overloading on the gear

reducer. Lubricate with proper products the hinges and the parts subject to sliding; when mounting the

screws it is recommended to apply locking adhesives.

Important! Concerning the reaction system, follow the project indications stated in the technical

catalogs Rossi. Whenever personal injury or property damage, due to falling or projecting parts of gear

reducer or of its parts, may occur, foresee adequate supplementary protection devices against:

– rotation or unthreading of the gear reducer from shaft end of driven machine following to

accidental breakage of the reaction arrangement;

– accidental breakage of shaft end of driven machine.

System kit using reaction disc springs (reaction recess).

For the mounting of the kit, use the tapped butt end

hole on the shaft end of the driven machine and the

fl at machined chamfered surface for compressine and

fi tting the disc springs into the reaction recess.

(50 ... 81, 125) (100)

Fig. 5.4.1. Bolts for foot fastening

UT.C 2119

Gear red.

size

Screw

UNI 5737-88

(l max)

40

M6 × 22

50

M8 × 30

63, 64

M10 × 35

80, 81

M12 × 40

100

M14 × 50

125, 140

M16 × 55

160, 180

M20 × 70

200, 225

M24 × 90

250, 280

M30 × 110

320 ... 360

M36 × 130

Loading...

Loading...