11

UTD.187.2019.09.00_EN Operating instructions G series

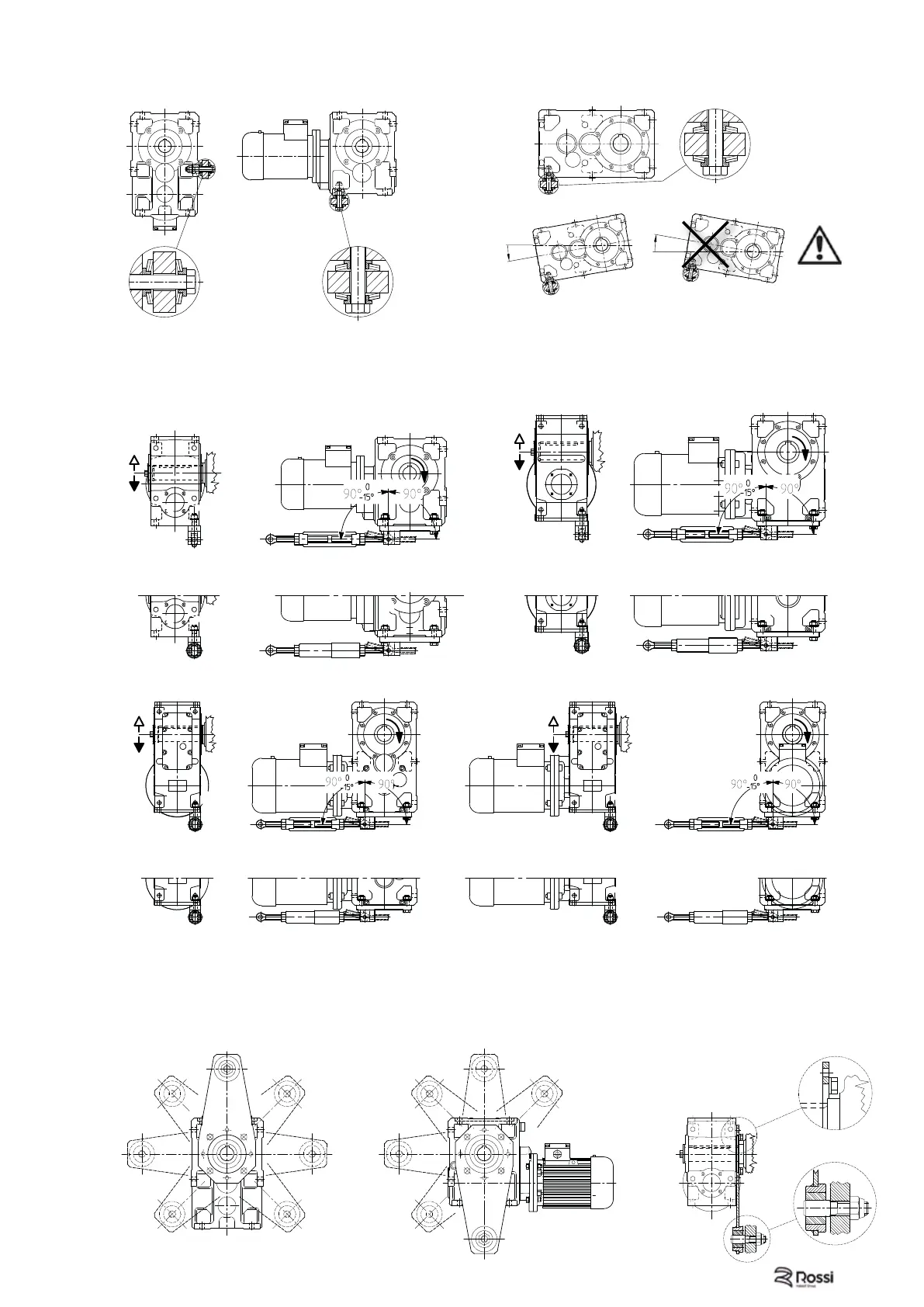

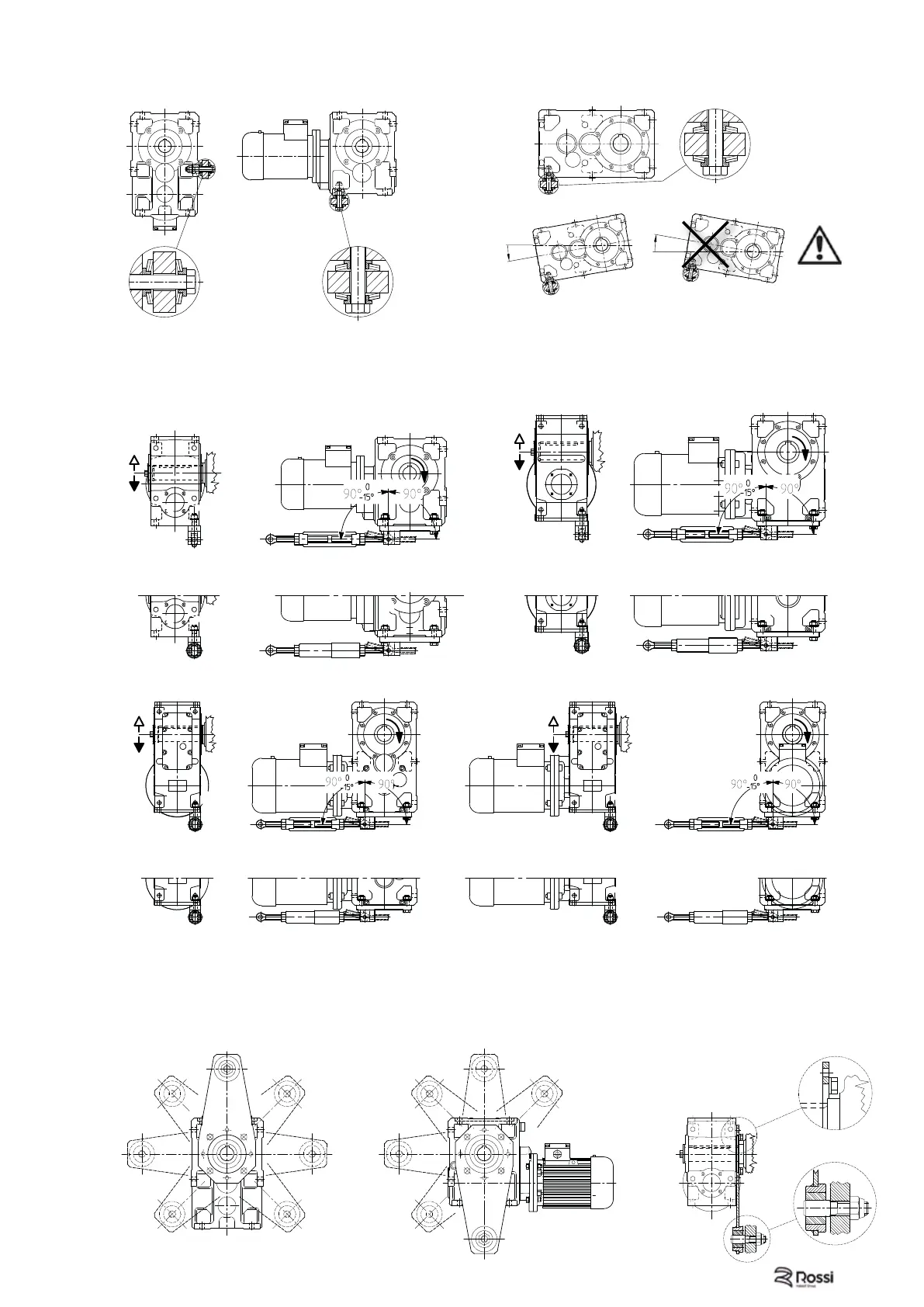

Reaction bolt using disc spring

For sizes 140 ... 360 C2I, 2I, 3I, in B3 or B8 mounting position, ensure that the housing oscillation, during

the running, does not overtake – towards the top – the horizontal position.

Rigid or fl exible torque arm using bracket

If the direction of rotation is opposite to that given in the fi g. rotate the torque arm by 180° (operation not

necessary in case of fl exible torque arm).

System with torque arm

According to dimensions, some ounting positions of motor fl ange torque arm could not be possible.

Before mounting the torque arm, carefully clean the torque arm, all coupling surfaces and apply locking

adhesives on the screws and on mating surfaces. Tighten the screws by a dynamometric wrench at values

shown in the table 5.2.1 «Tightening torques».

UT.C 2121

UT.C 2122

Loading...

Loading...