41

UTD.187.2019.09.00_EN Operating instructions G series

12 - Gear reducer troubles: causes and corrective actions

See specific motor documentation.

NOTE

When consulting Rossi state:

– all data on gear reducer or gearmotor name plate;

– failure nature and duration;

– when and under which conditions the failure occured;

– during the warranty period, in order not to loose validity, do not disassemble nor tamper the gear reducer or gearmotor without approval by Rossi.

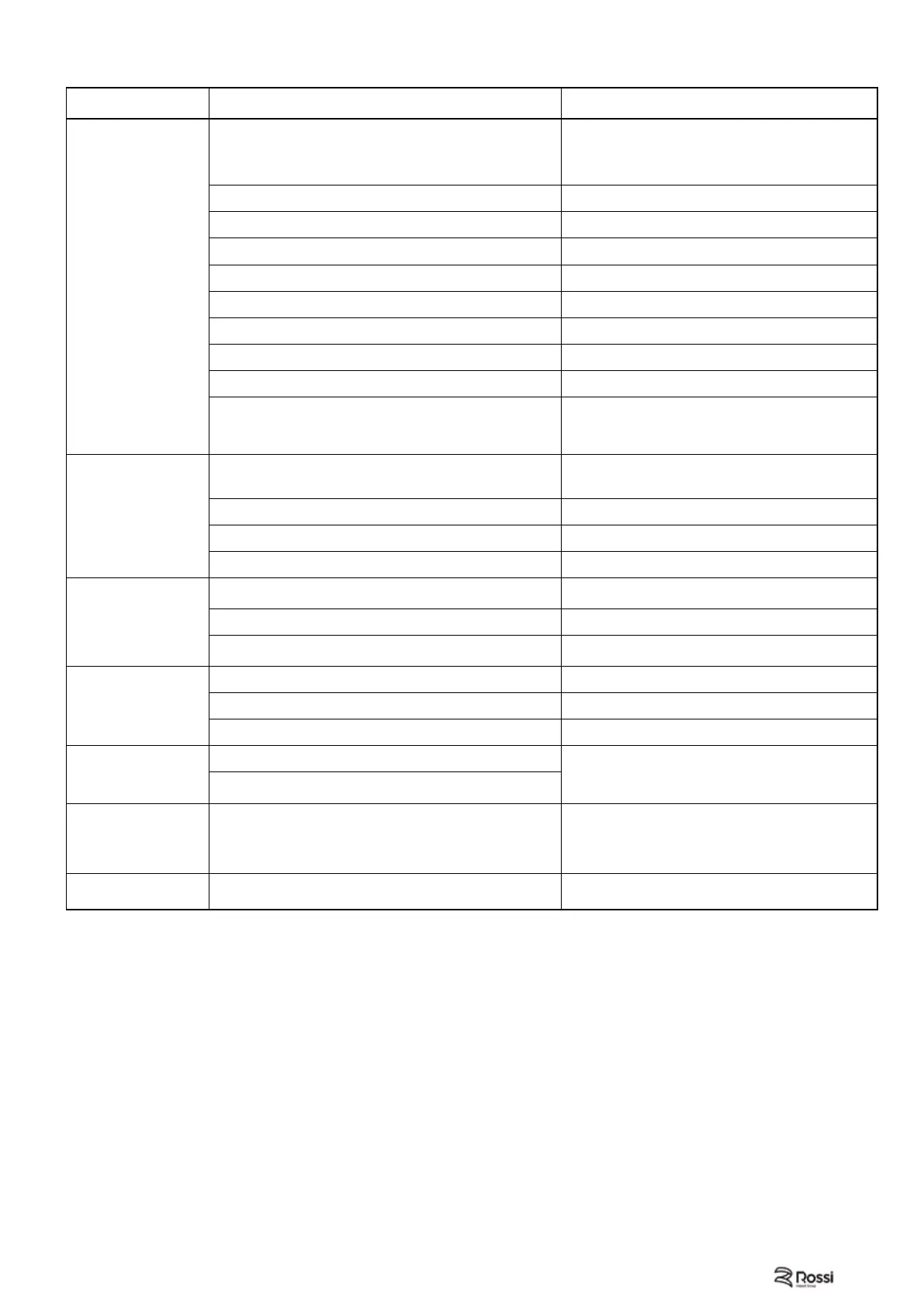

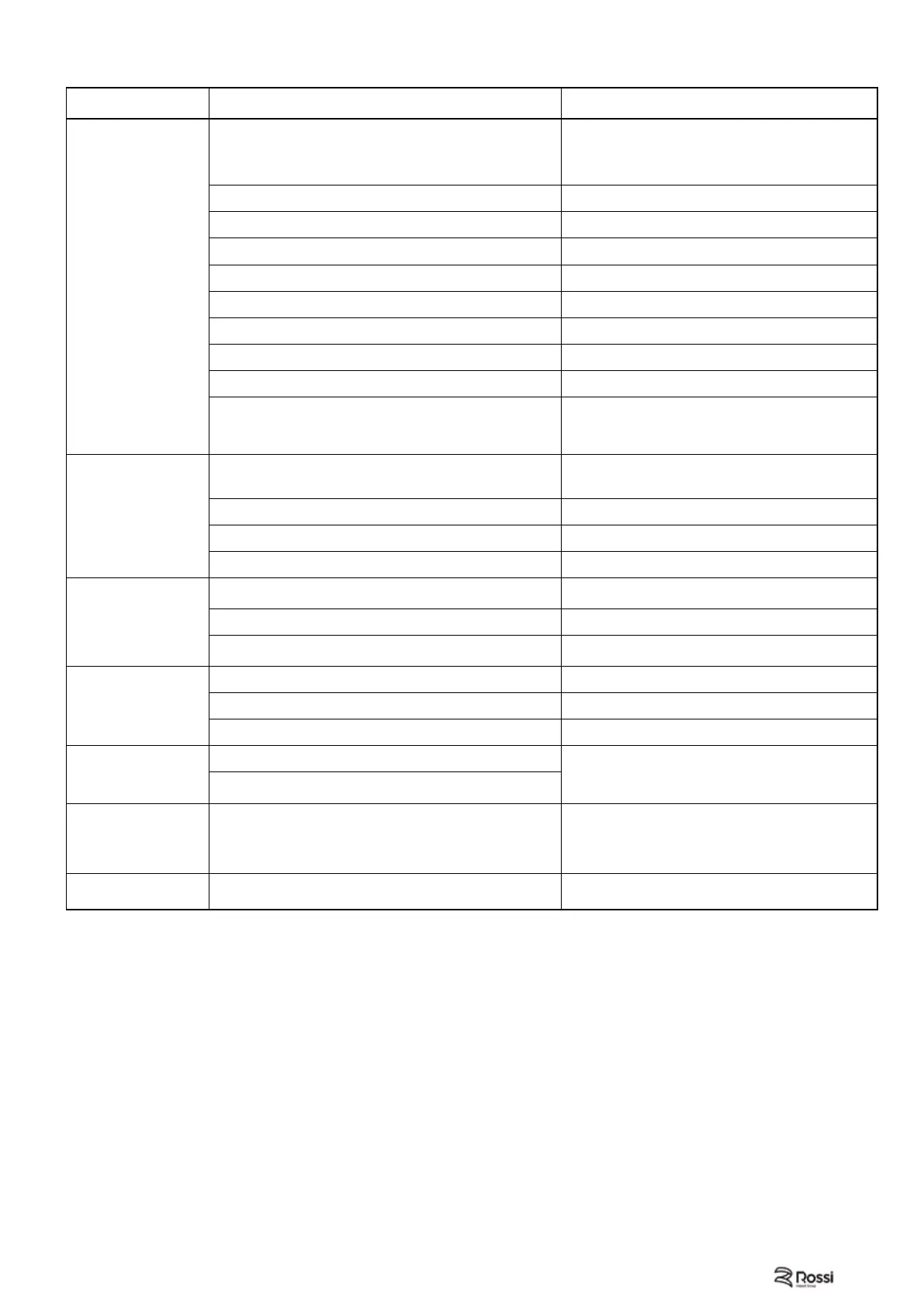

Trouble Possible causes Corrective actions

Excessive oil

temperature

Inadequate lubrication:

– excessive of insufficient oil quantity

– unsuitable lubricant (different type, too viscous, exhausted,

etc.)

Check

– oil level (gear reducer at rest) or quantity

– lubricant type and/or state (see ch. 6.2, lubrication

table) and replace if necessary

Incorrect mounting position Change the mounting position

Too tightened taper roller bearings Consult Rossi

Excessive ambient temperature Increase the cooling or correct the ambient temperature

Obstructed passage of air Eliminate obstructive material

Slow or missing air recycle Arrange auxiliary ventilation

Radiance Screen gear reducer and motor properly

Inefficiency of auxiliary bearing lubrication system Check the pump and the pipes

Bearings failure, defect or bad lubrication Consult Rossi

Inefficient or out of service oil cooling system: obstructed

filter, insufficient oil (exchanger) or water (coil) flow rate,

pump out of service, water temperature > 20 °C, etc.

Check the pump, the pipes, the oil filter and safety

devices efficiency (manostats, thermostats, etc.)

Anomalous noise One or more teeth with

– dents or spallings

– excessive flanks roughness

Consult Rossi

Bearings failure, defect or bad lubrication Consult Rossi

Taper roller bearings with excessive clearance Consult Rossi

Vibrations Check the fastening and the bearings

Lubricant leaking from

seal ring

Seal ring with worm, bakelized, damaged or false mounted

seal lip

Replace seal ring (see ch. 11.4)

Damaged rotating seating (scoring, rust, dent, etc.) Restore the seating

Mounting position differs from the one stated on the name

plate

Correctly position the gear reducer

Oil leaking from filler

plug

Too much oil Check oil level/quantity

Incorrect mounting position Check mounting position

Inefficient vent valve Clean/replace filler plug with vent valve

Low speed shaft not

rotating even if high

speed shaft or motor

are running

Broken key Consult Rossi

Completely worn gear pair

Lubricant leaking from

joints (covers or half-

housing joints)

Defective oil seals Consult Rossi

Water in the oil Defective cooling coil or heat exchanger Consult Rossi

Loading...

Loading...