5

UTD.187.2019.09.00_EN Operating instructions G series

2 – Application conditions and limits

Gear reducers are designed for industrial applications according to catalog data, ambient temperature 0 ÷ +40

°C (with peaks at -10 °C and +50 °C), maximum altitude 1 000 m.

Not allowed running conditions: application in aggressive environments having explosion danger, etc. Ambient

conditions must comply with specifi cations stated on name plate.

3 – How supplied

3.1 - Receipt

At receipt verify that the unit corresponds to the one ordered and has not been damaged during the

transport, in case of damages, report them immediately to the courier.

Do not commission gear reducers and gearmotors that are even slightly damaged.

Report any non-compliance to Rossi.

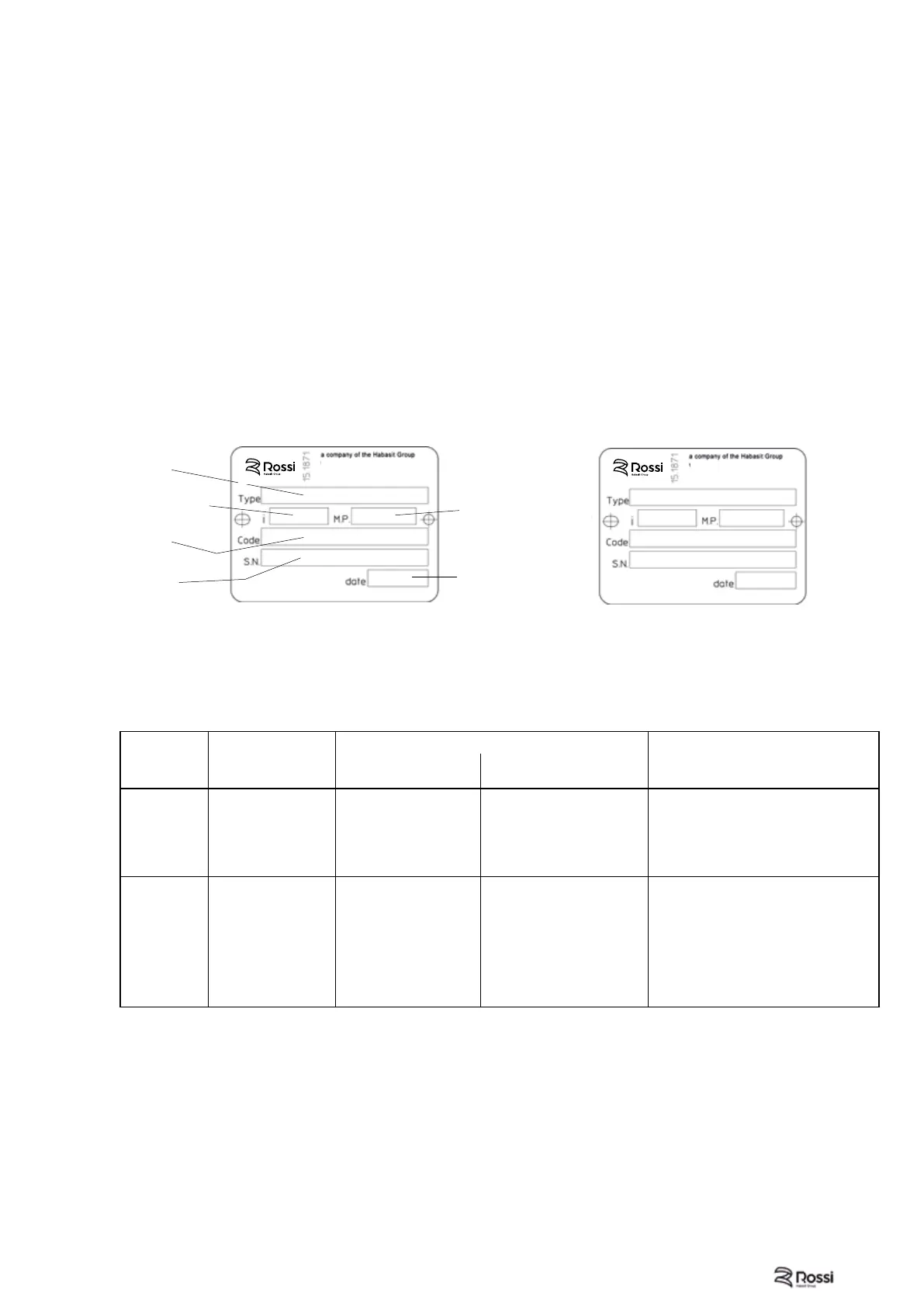

3.2 - Name plate

Every gear reducer is provided with a name plate in anodized aluminium containing main technical information

relevant to identifi cation; the name plate must not be removed and must be kept integral and readable. All

name plate data must be specifi ed on eventual spare part orders.

Product assembled by Rossi Italy

1) Before adding further coats of paint, properly protect the seal rings and carefully degrease and sand the gear reducer surfaces (instead

of sanding, it is possible to apply a coat of water-soluble primer).

Size

gear reducer

Internal painting External painting Notes

Final color

blue RAL 5010

Features

40 … 81

Epoxy powder (pre-

painted)

Epoxy powder

(prepainted)

Resistant to atmospheric

and aggressive agents.

(corrosivity class C3

according to ISO 12944-2)

Suitable for further coats of

dual-compound paints

1)

Machined parts remain

unpainted and are protected

with an easily removable antitrust oil

(before painting remove the protective

oil).

100 … 360

Single

compound

ester epoxy or

phenolic resin basis

primer

(prepainted)

Single

compound exter epoxy

or phenolic resin basis

primer

(pre-painted)

+

Water-soluble polyure-

than dual-compound

enamel

Resistant to atmospheric

and aggressive agents.

(corrosivity class C3

according to ISO 12944-2)

Suitable for further coats of dual-

compound paints only 1).

Machined parts are painted with

water-soluble

polyurethan dual-compound enamel

The internal painting does not

resist polyglycol synthetic oils

(polyalphaolefines synthetic oils are

suitable).

Remove by a scraper or solvent, if

present, the eventual paint of gear

reducer coupling surfaces

3.3 - Lubricant

Unless otherwise stated, the gear reducers sizes 40 ... 81 are supplied complete with synthetic oil whereas

for sizes 100 ... 360 gear reducers are supplied without lubricant.

3.4 - Painting

3.5 - Protections and packing

Overhanging free shaft ends and hollow shafts are treated with protective anti-rust long life oil and protected

with a plastic (polyethylene) cap (only up to D 48 mm for overhanging shafts, D 110 mm for hollow shafts).

All internal parts are protected with protective anti-rust oil.

Unless otherwise agreed in the order, products are adequately packed: on pallet, protected with a polyethylene

fi lm, wound with adhesive tape and strap (bigger sizes); in carton pallet, wound with adhesive tape and strap

(smaller sizes); in carton boxes wound with tape (for small dimensions and quantities). If necessary, gear

reducers are conveniently separated by means of anti-shock foam cells or of fi lling cardboard.

Do not stock packed products on top of each other.

Product assembled by Rossi ACs

assembled by Rossi North America

Transmission

ratio

Gear reducer

type

Product code

Mounting

position

Date

Serial

number

www.rossi.com

www.rossi.com

Loading...

Loading...