BRP-Rotax

REPAIR MANUAL

CONSUMABLE MATERIALS

General note

ATTENTION

Use only the specified or technically equivalent materials from BRP-Rotax for all

maintenance work. When handling chemicals, comply with all the customary regula-

tions and specifications of the producer, including the expiry date and instruction.

NNOOTTEE

If necessary contact the manufacturer concerning the comparability of the con-

sumable materials. In some cases information can be obtained from the local au-

thorized distributors and service partners for ROTAX engines.

NNOOTTEE

Respect the manufacturers instruction concerning the curing time and the expire

date of the particular surface sealing compound.

The materials specified have been tested for a long time and are suitable for all operating

conditions indicated by the manufacturer.

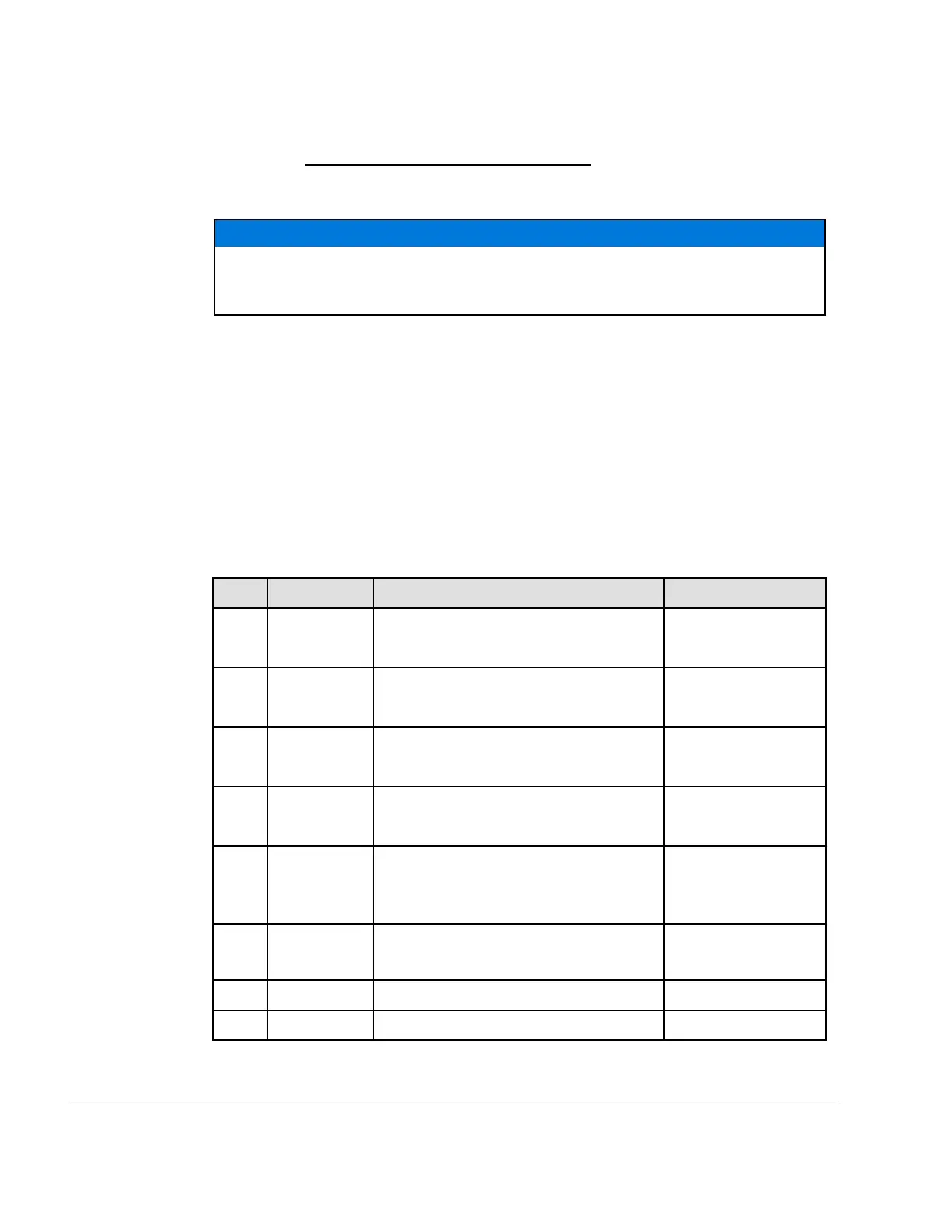

No. Part no. Description, Application

Qty.

1 897651

LOCTITE 243 blue,

medium-duty screw securing agent

10 ml (0.003 US gal.)

2 899788

LOCTITE 648 geen,

high strength screw securing agent

5 ml (0.001 US gal.)

3 297434

LOCTITE Anti-Seize 15378,

for the prevention of fretting corrosion

50 g (0.11 lb)

4 897161

MOLYKOTE 111

long-term lubricant for shaft seal

100 g (0.22 lb)

5

897330

Lithium-based grease or Dow

Corning

to prevent leakage current

250 g (0.55 lb)

6 25473

XPS Kart TEC DD2 Kart Gear oil

Lubricant

1000 ml (0.26 US

gal)

7

296160 Engine gasket set 1

–

n.a.

Cleaning agents

as required

Chapter 2

Page 6

Effectivity: 125 MAX evo, Junior MAX

evo, Mini MAX evo, Micro MAX evo

Edition - February 01 2018 /Rev. 0

Loading...

Loading...