Section 03 787 RFI ENGINE

Subsection 04 (BOTTOM END)

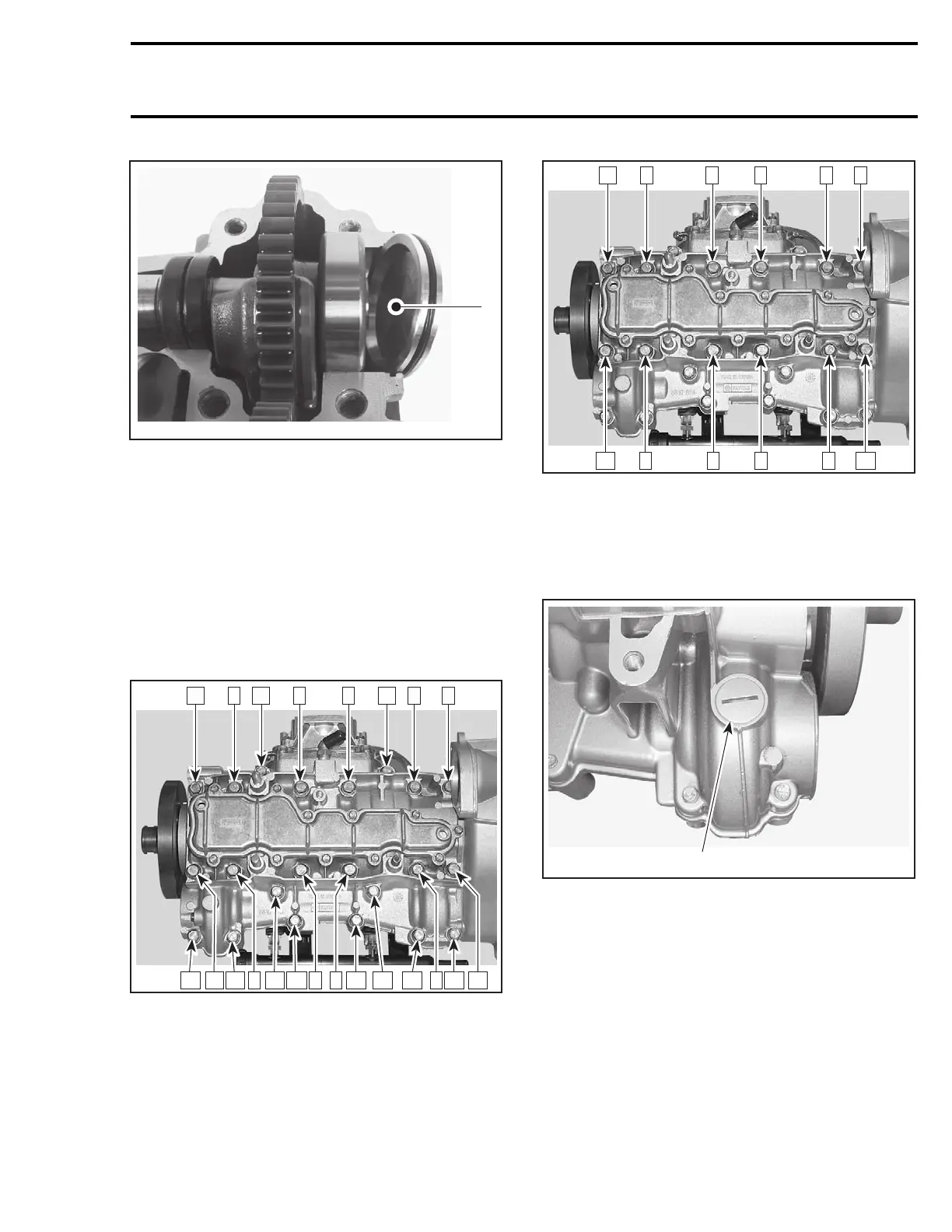

F00D0QA

1

1. Hollow side facing bearing

Crankcase Halves

Assemble crankcase halves.

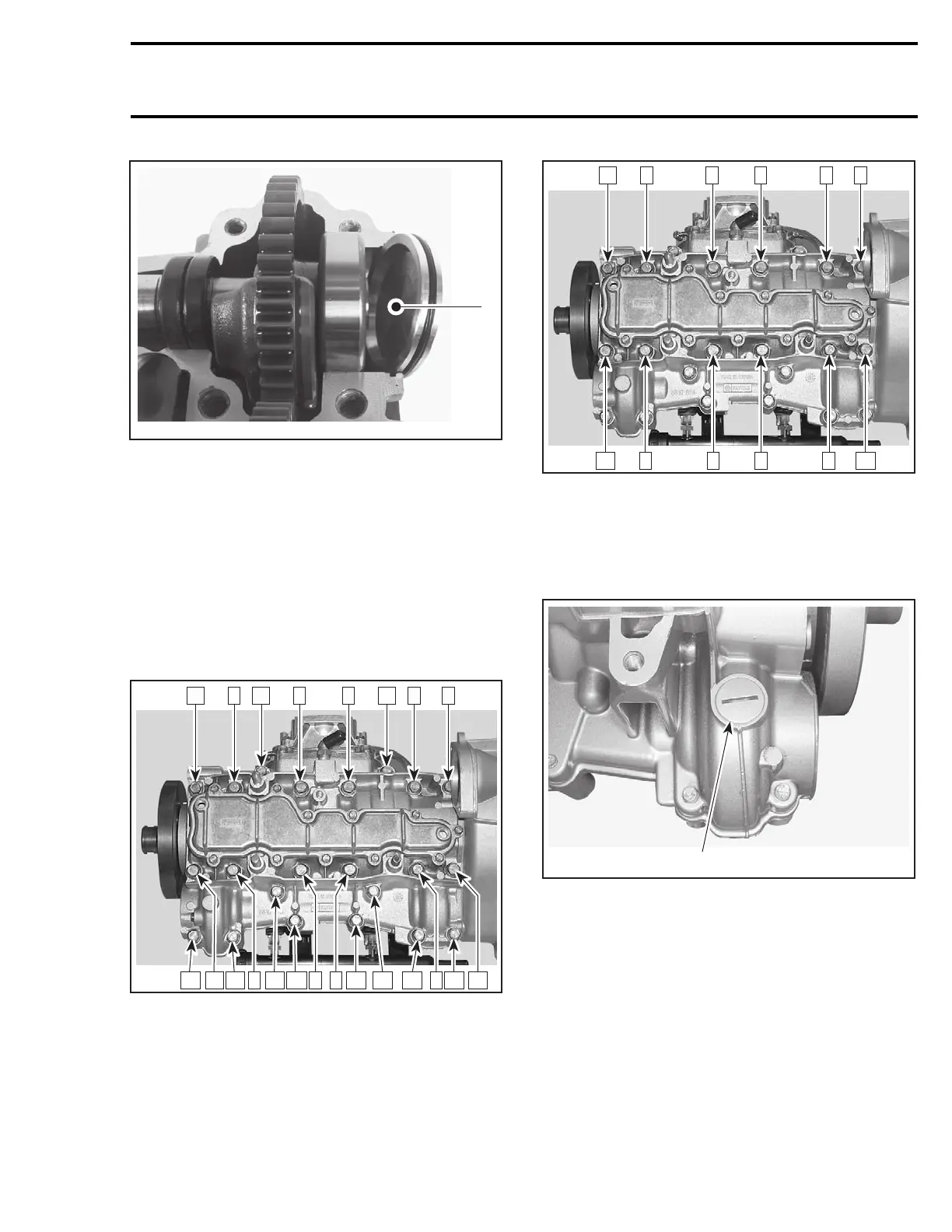

Crankcase Screws

Apply Loctite 518 (P/N 293 800 038) on screw

threads and Molykote 111 (P/N 413 707 000) be-

low head screws.

Torque crankcase screws to 12 N•m(106lbf•in)

as per following sequence. Repeat procedure,

retightening all screws to 24 N•m(17lbf•ft).

11

F15D05B

7 21 1 3 22 5 9

819 12 17 13 15 4

2

16 14 18

6

20 10

As a final step, torque only M10 screws no. 8 of

crankcase to 40 N•m(30lbf•ft) as per following

sequence.

F15D05C

11 7 1 3 5 9

812 4

6

102

Counterbalance Shaft Gear Oil

When crankcase assembly is completed, add

30 mL (1 oz) of motor oil SAE 30 to the counter-

balance shaft gear through the crankcase filler

plug.

F07D06A

1

1. Remove plug and add SAE 30 motor oil

Oil Fittings

If inlet and outlet oil fittings no. 11 of rotary valve

shaft have been removed from crankcase, rein-

stall them with their end pointing toward ignition

housing. Apply Loctite 518 (P/N 293 800 038) on

threads of fittings.

PTO Flywheel

Install O-ring onto crankshaft.

smr2005-083 99

Loading...

Loading...