Section02717ENGINE

Subsection 03 (TOP END)

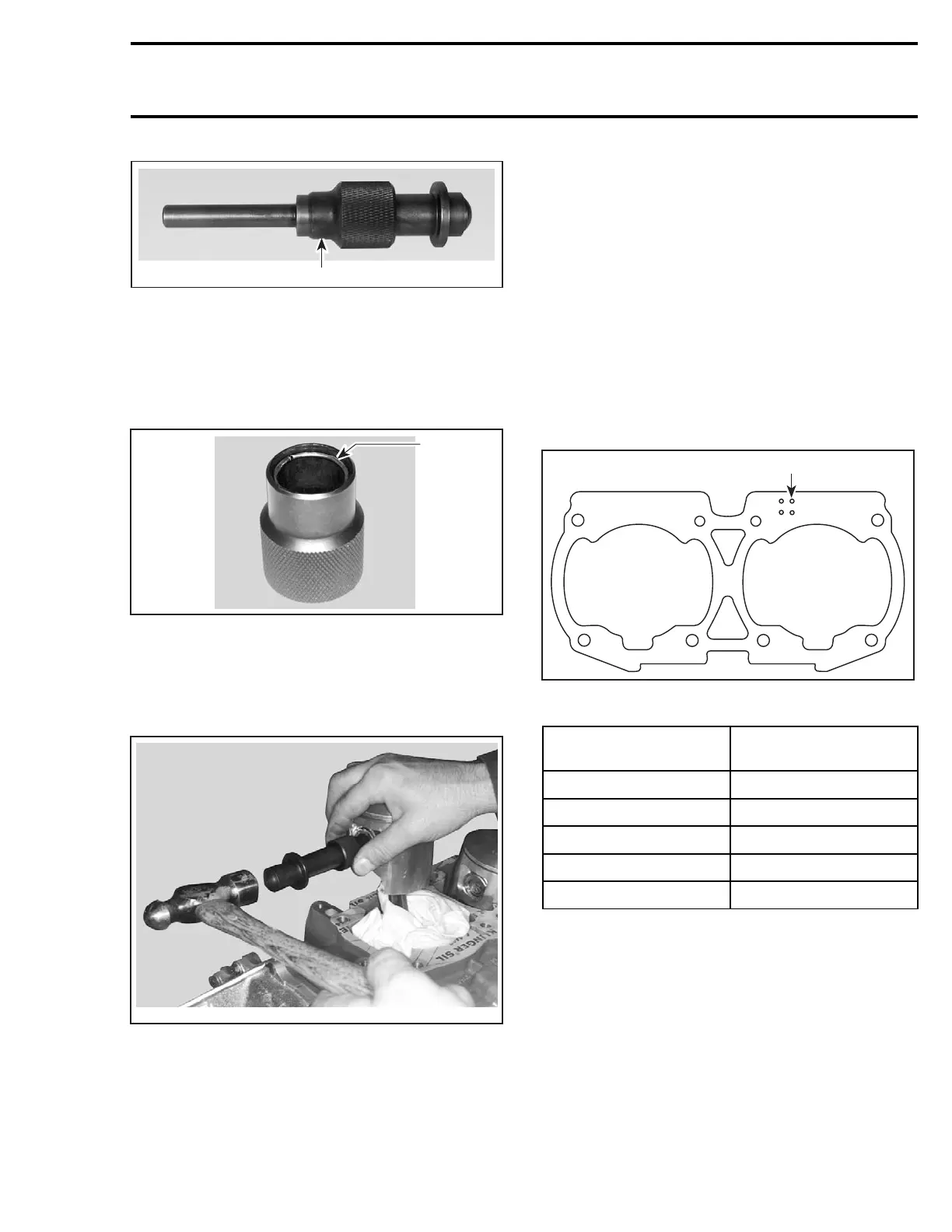

F06B01A

1

TYPICAL

1. Circlip installer

– Remove sleeve from pusher then insert circlip

into its bore.

– Reinstall sleeve onto pusher and push until cir-

clip comes in end of tool.

F00B0QA

1

TYPICAL

1. Circlip near end of tool

– Position end of tool against piston pin opening.

– Firmly hold piston against tool and tap tool with

a hammer to insert circlip into its groove.

F00B0RA

TYPICAL

CAUTION: The hand retaining the piston

should absorb the energ

ytoprotectthecon-

necting rod.

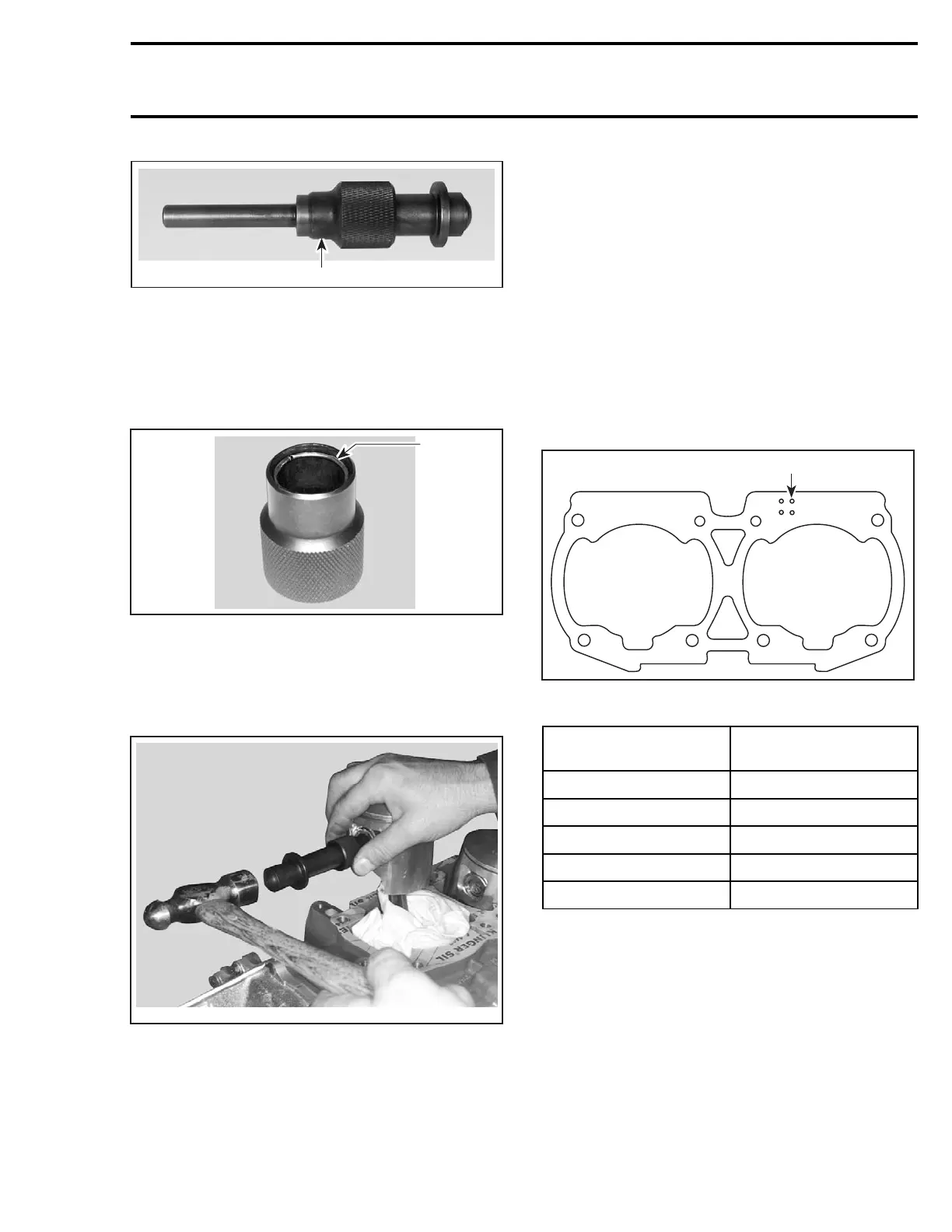

Cylinder Base Gasket

NOTE: The general procedure is to install a new

gasket of the same thickness. However, if you do

not know the gasket thickness that was installed

or if a crank repair has involved replacement of

connecting rods, refer to COMBUSTION CHAM-

BER VOLUME MEASUREMENT in ENGINE MEA-

SUREMENT section to properly determine the re-

quired gasket thickness.

Different thicknesses of cylinder base gaskets

no. 13 are used for a precise adjustment of the

combustion chamber volume.

To identify gasket thickness, refer to the identifi-

cation holes on the gasket.

F01D67A

1

TYPICAL

1. Identification holes

GASKET THICKNESS

IDENTIFICATION

HOLES

0.3 mm (.012 in) 3

0.4 mm (.016 in)

4

0.5 mm (.020 in)

5

0.6 mm (.024 in) 6

0.8 mm (.031 in) 8

Cylinder

To easily slide cylinder no. 6 over piston no. 8,use

the piston ring compressor (P/N 420 876 979).

smr2005-077 33

Loading...

Loading...