Reference

Modification no.

- 0 -

Page

232

Date

1997 02 01

Main

914 F

01480

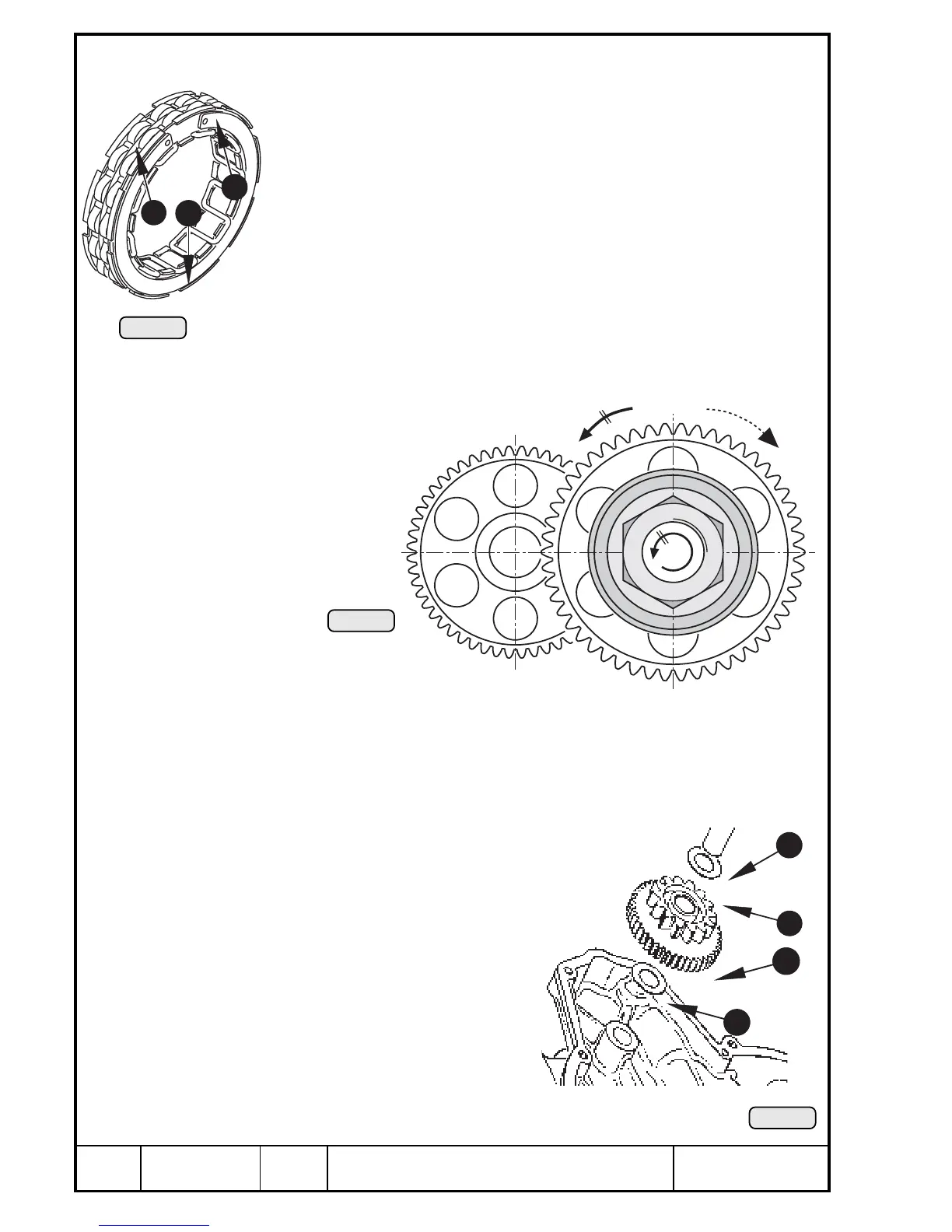

14.2.3) Sprag clutch — installation

See Pic. 202, 204, 205 and 206.

Place sprag clutch into clutch housing with brake clip E visible. At fitting

of brake clip, compress slightly using circlip pliers and ensure that clip

remains in position and engages fully on the catches in sprag unit {. Fit

retaining ring W.

Lock crankshaft using fixing screw 241 965. Degrease taper and threads

of crankshaft and taper of clutch housing. Coat taper of clutch housing

thinly with LOCTITE 221 and fit on crankshaft. Turn free-wheel gear to

facilitate aligning of the sprags E.

◆ NOTE: The free-wheel gear } gear must engage on crankshaft

when turning anti-clockwise, looking towards magneto side

of engine, and turn freely when turning clockwise.

Secure degreased hex. nut M34x1,5

with LOCTITE 221 and tighten to

120 Nm (1060 in.lb).

◆ NOTE: Hex. nut with left hand thread.

■ ATTENTION: Check axial clearance of free-wheel gear, see Pic. 202 and

dimension P in Chapter 15).

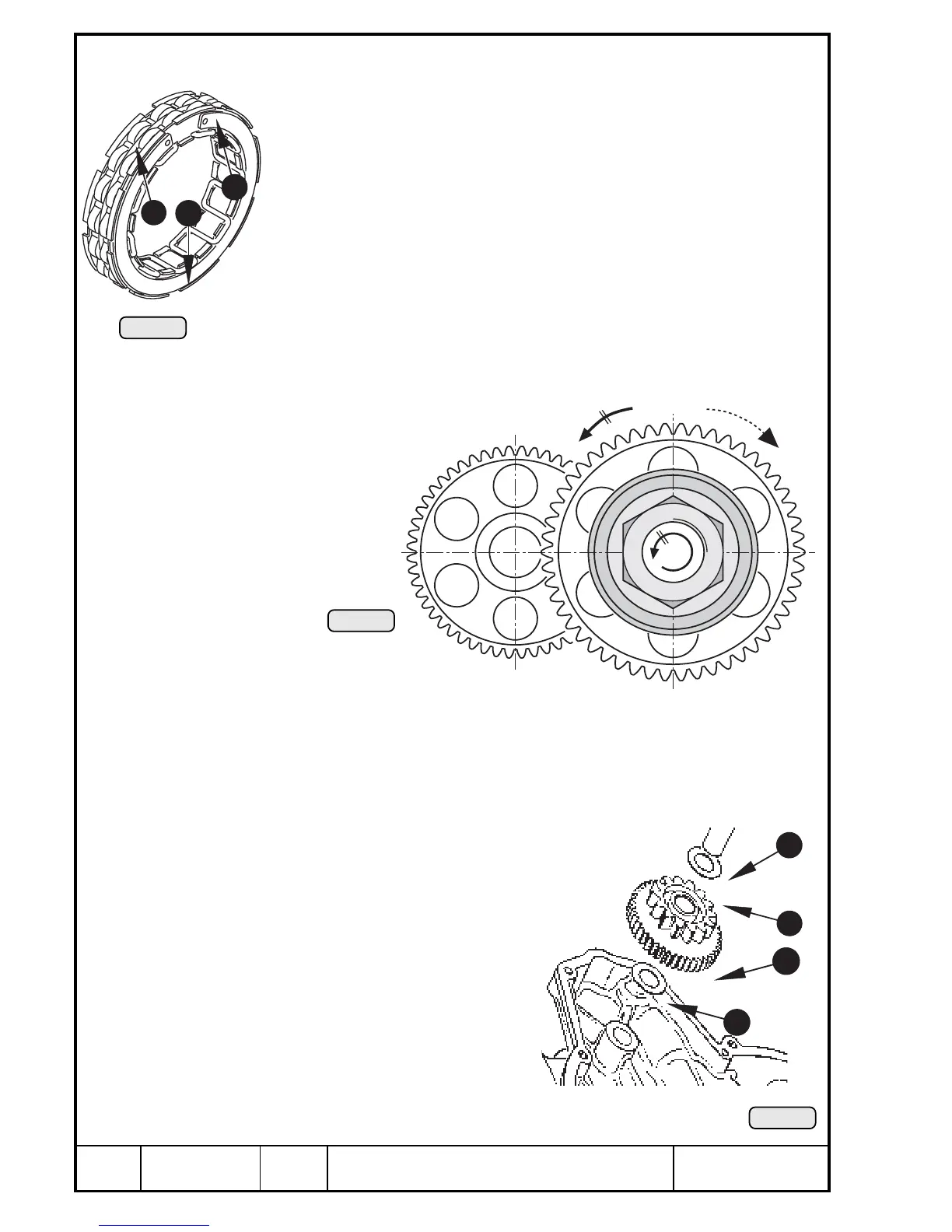

14.2.4) Reduction gear for electric starter

See Pic. 207.

Place thrust washer Q 12,5/21,5/1 onto crankcase. Place

intermediate gear W into position, lubricate intermediate

gear shaft E and push into position. Fit thrust washer

R 12,5/21,5/1 on top of it.

14.2.5) Fitting of ignition housing

See Chapter 13.3.9).

5

11

3

Pic. 206

4

3

2

1

Loading...

Loading...