Cutout (WxH): 2.967” (75.4mm) x 3.145”(79.9mm)

Outside edge (WxH): 3.425”(87mm) x 3.425”(87mm)

Depth in-wall (including Ethernet jack): 2.36”(59.95mm)

MOUNTING HEIGHT

The recommended mounting height for the WK2 is between 54 inches (1.37m)

and 60 inches (1.52m) from the bottom of the glass keypad.

REAR HOUSING INSTALLATION

Two mounting wings (included) may be used to secure the WK2 to drywall.

Alternate methods of mounting the rear housing include:

• A metal conduit box (sold separately) is available for new construction and

installations that require a metal enclosure.

• Four screw holes located on the rear housing may also be used for mounting

in situations where mounting wings are not possible (wood paneling, concrete

etc). Visit the WK2 product support webpage for more information.

IMPORTANT NOTES:

• Testing the WK2 power up and Ethernet activity MUST be done prior to

applying the adhesive used to secure the unit during installation (see steps

below). Once the adhesive is used, it will be very difcult to remove the WK2.

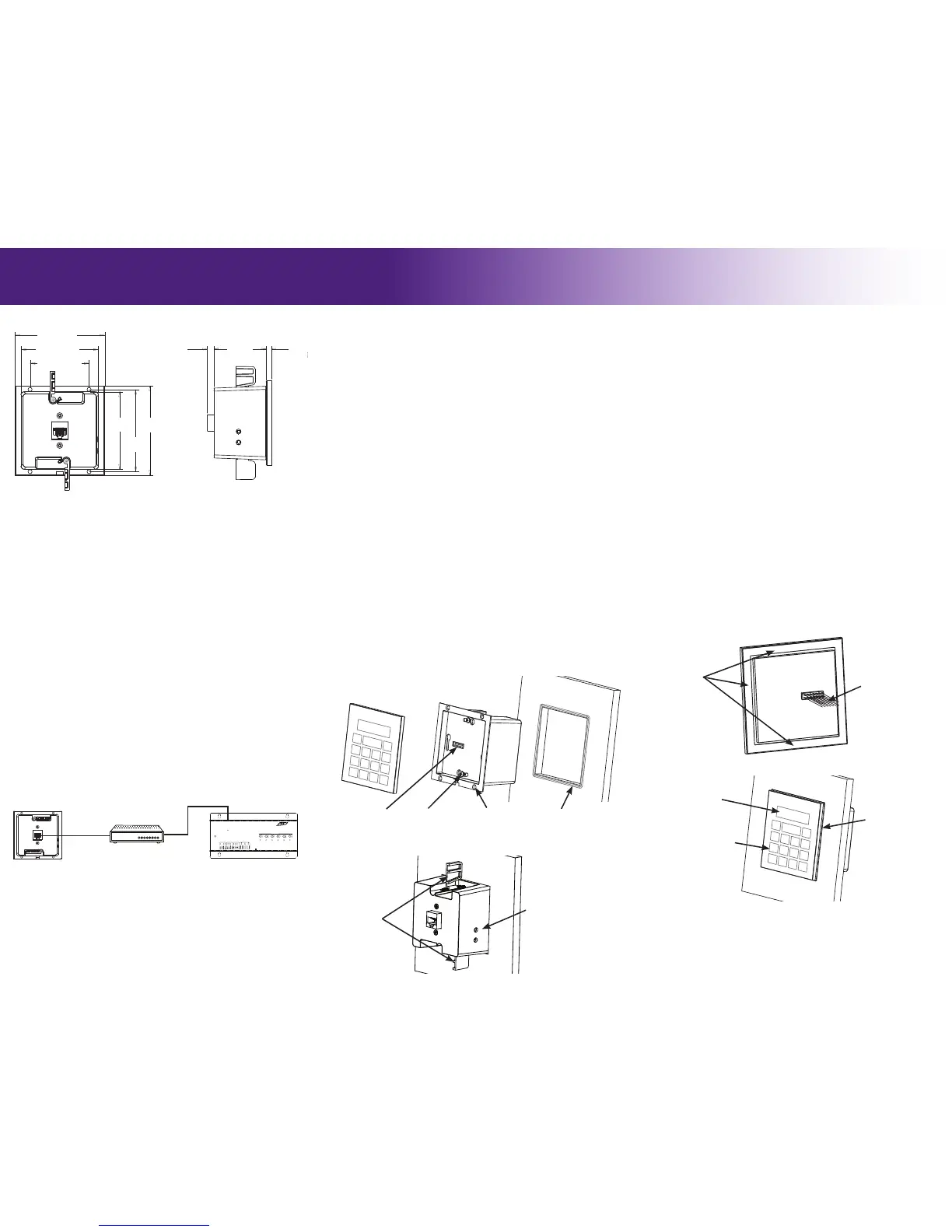

INSTALLATION USING MOUNTING WINGS:

1. Use the included cut-out template to mark and cut the opening in the wall.

2. Test WK2 power up and activity. Pull Ethernet cable though wall opening

and plug it in to test the WK2 power up and activity. Activity LED lights are

viewable through two rear housing holes (see diagram below).

3. Remove the glass keypad from the rear housing assembly by pulling apart

gently - DO NOT twist or tilt the glass keypad side to side during removal.

4. Install the mounting wings on to the rear housing. Place a mounting wing on

the rear housing in the appropriate orientation (see diagram), aligned with

the screw hole, insert the screw and tighten until the screw protrudes from

mounting wing slightly. Repeat for mounting wing on opposite side.

5. For waterproof installations (optional): Test t rear housing assembly in

wall opening and remove. Seal along the edge of the wall opening with a bead

of silicone or paintable latex sealant. (* See diagram below)

6. Place rear housing assembly (glass keypad removed) in the wall opening and

align, then tighten the mounting wing screws until snug - DO NOT over-

tighten.

It’s Under Control

®

COMMUNICATION AND CONTROL

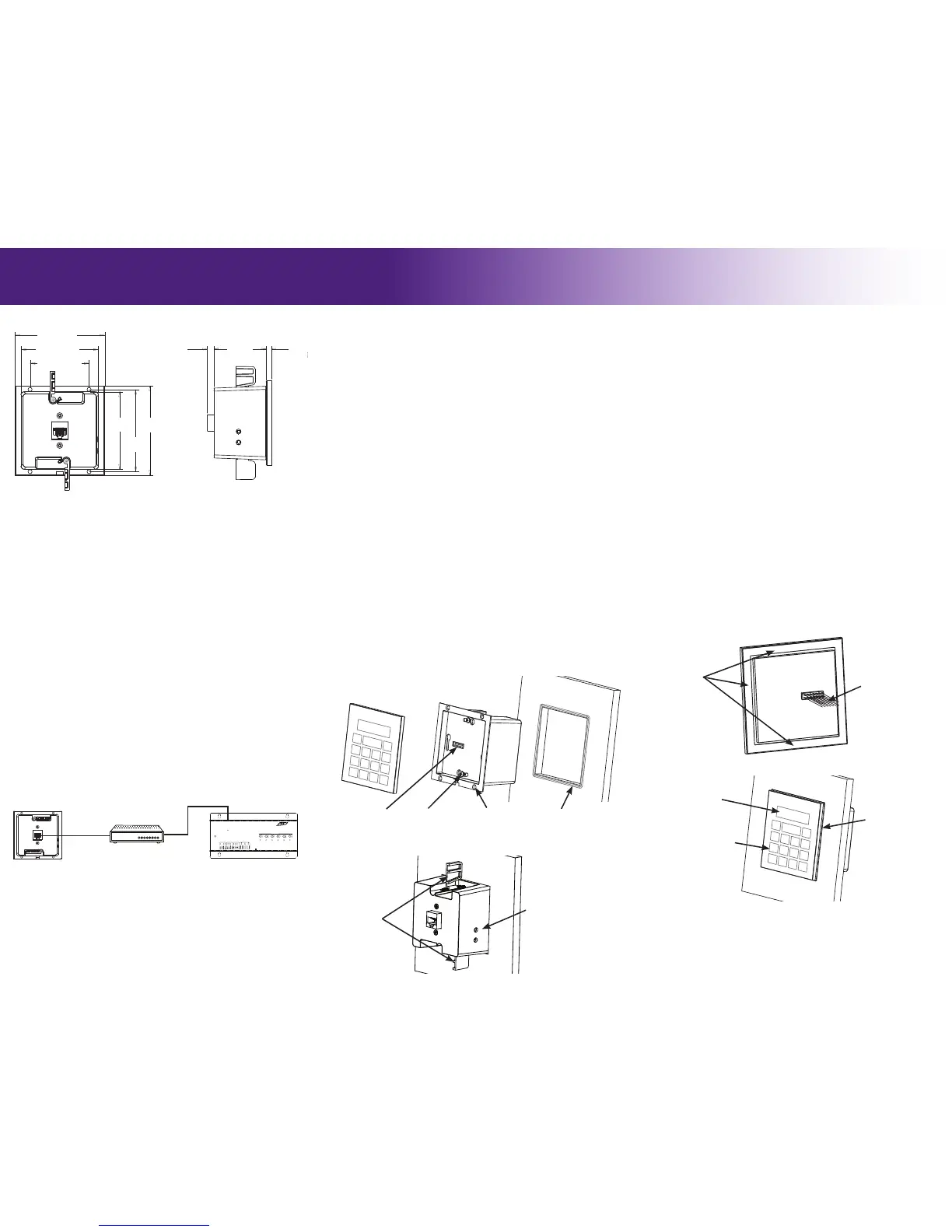

The WK2 is powered using Power-Over-Ethernet (PoE).

IMPORTANT NOTES:

• An 802.3af compliant Power-over-Ethernet router/switch (Class #2) must be

used to avoid potential performance issues or damage to the unit.

• The WK2 CANNOT be powered from an external power supply, an RTI CB8

connecting block or an RTI control processor.

POWERING THE WK2

WK2

MOUNTING

WK2 (Rear)

RESET

ETHERNET

EXPANSION

PORT 1 PORT 2 PORT 3

PORT 4

PORT 5

PORT 6

+

+ +

+ +

+

USB

RTI COM

POWER

STATUS

RS-232

POWER / IR

+12VDC TRIGGER

+3-24VDC SENSE

RELAYS (+30VDC, 5A MAX)

IR OUTPUT LEVEL

1

2

Model XP-6

Advanced Control Processor

RTI XP-6

Silkscreen Graphics

May 27, 2010

Scale 1:1

DOCUMENT NO.

REV

ECO

REVISION RECORD

DESCRIPTION

DRFT

A

B

C

D

1234

D

C

B

A

4 3 2 1

DATE

MM(INCH)

25.4MM=1 INCH

TOLERANCES EXCEPT AS NOTED

MM

0

±

.0

±

.00

±

ANGLES

±

MATERIAL

FINISH

INCHES

.0

±

.00

±

.000

±

DATE

DATE

DATE

DATE

DFTG

CHKD

MFG

APPVL

INTERPRET PER ANSI Y14.5

THIRD ANGLE PROJECTION

MODEL

TITLE

SIZE

DO NOT SCALE DRAWING

DET LISTS

YES

NO

SHT OF

REV

REMOTE TECHNOLOGIES INC.

SHAKOPEE, MN 55379

DOCUMENT NO.PART NO.

THIS IS AN UNPUBLISHED WORK CONTAINING REMOTE

TECHNOLOGIES INC. CONFIDENTIAL AND PROPRIETARY

INFORMATION. DISCLOSURE, USE OR REPRODUCTION

WITHOUT THE WRITTEN AUTHORIZATION OF REMOTE

TECHNOLOGIES INC. IS STRICTLY PROHIBITED.

01 ----- ----- PRELIMINARY RELEASE DRF

WK-2 USER MANUAL

01

1 1

ASSEM . WK-2-TOTAL

RTI 01/15/15

°

0.850SCALE

(Cat-5)

Ethernet Router/Switch

(PoE Class#2)

WK2 Rear Housing - Mounted In Wall

.262”

[6.65mm]

2.098”

[53.3mm]

.220”

[5.6mm]

2.967” [75.4mm]

2.971”

[75.5mm]

2.260” [57.4mm]

3.145”

[79.9mm]

4.555”

[115.7mm]

3.425” [87mm]

3.425”

[87mm]

PROGRAMMING THE WK2

The WK2 is programmed using the RTI Integration Designer Programming

Software. The WK2 system le will be downloaded to the unit via the XP

processor - no direct download to the WK2 is required.

UPDATING FIRMWARE

The WK2 rmware is not user-upgradeable.

WK2 DIMENSIONS

3.425”

[87mm]

3.425”

[87mm]

.262”

[6.65mm]

2.098”

[53.3mm]

.220”

[5.6mm]

2.967” [75.4mm]

2.971”

[75.5mm]

2.260” [57.4mm]

3.145”

[79.9mm]

.443”

[11.25mm]

4.555”

[115.7mm]

3.425” [87mm]

3.425”

[87mm]

WK2 (Rear Housing)

(Cutout, Mounting Hole, Outside Edge Dimensions)

WK2 (Side view)

Drywall

Mounting Wing

ETHERNET PORT

The WK2 Ethernet Port provides communication with a 10/100 Base-T Ethernet

network (LAN) using a Power-over-Ethernet (PoE) router/switch for control via

an RTI XP series control processor. The port is compatible with Cat-5 cable with

an RJ-45 termination

IMPORTANT NOTES:

• The WK2 must be used with an RTI XP series control processor. It will not

function as a standalone controller.

• There is a MAC address card included with the WK2, which will be used during

the programming process to identify the unit.

ADDING THE WK2 TO THE ETHERNET NETWORK (LAN)

Wire the WK2 to the Ethernet network and the unit will power on. The network

router will assign an IP address to the WK2 automatically and allow it to join the

network.

• The WK2 is set to use DHCP by default.

• Network router must have DHCP enabled.

CONFIGURING THE WK2 USING THE WEB INTERFACE

The WK2 web interface is accessible via a standard web browser and is used to

set a static IP address and change the network “Host Name” of the unit.

IMPORTANT NOTE:

• Setting a static IP address is NOT necessary and is generally discouraged. The

WK2 will nd the RTI control system automatically on the network so a static

IP address is unnecessary.

If a static IP address must be used, visit the dealer section of rticorp.com, and

go to the WK2 product support webpage for specic details on how to access the

web interface and set the static IP address.

Holes for viewing Ethernet

activity lights.

GLASS KEYPAD INSTALLATION

Once the WK2 rear housing assembly is mounted in the wall, the glass keypad is

installed. Follow steps closely for installations where moisture may be present.

IMPORTANT NOTES:

• The glass keypad to rear housing alignment MUST be done prior to applying

the adhesive that is used to secure the unit during nal installation (see steps

below). Once the adhesive is used, it will be very difcult to adjust the WK2.

INSTALLATION STEPS:

1. Inspect glass keypad to rear housing alignment. Install the glass keypad

on to the rear housing assembly by carefully aligning and inserting the 14

pins into the connector located on the controller board. All sides of the glass

keypad should be equal distance from the rear housing edges. If the sides are

not aligned, remove the glass keypad and adjust the two #4 screws anchoring

the controller board to the rear housing (see rear housing installation

diagram). Re-install glass keypad, re-inspect and repeat these steps until

aligned properly.

2. Remove adhesive gasket release liner, located on the backside of glass keypad

along the outside edge.

3. Carefully align pins on backside of glass keypad with controller board

connector, level and center glass keypad then press into place until ush with

rear housing.

4. Press the outside edge of the glass keypad until the adhesive gasket seats to

the rear housing lip.

5. For waterproof installations (optional): After the glass keypad is

installed, apply a bead of sealant around the outside perimeter of the glass

keypad. (* See diagram below)

DOCUMENT NO.

REV

ECO

REVISION RECORD

DESCRIPTION

DRFT

A

B

C

D

1234

D

C

B

A

4 3 2 1

DATE

MM(INCH)

25.4MM=1 INCH

TOLERANCES EXCEPT AS NOTED

MM

0

±

.0

±

.00

±

ANGLES

±

MATERIAL

FINISH

INCHES

.0

±

.00

±

.000

±

DATE

DATE

DATE

DATE

DFTG

CHKD

MFG

APPVL

INTERPRET PER ANSI Y14.5

THIRD ANGLE PROJECTION

MODEL

TITLE

SIZE

DO NOT SCALE DRAWING

DET LISTS

YES

NO

SHT OF

REV

REMOTE TECHNOLOGIES INC.

SHAKOPEE, MN 55379

DOCUMENT NO.PART NO.

THIS IS AN UNPUBLISHED WORK CONTAINING REMOTE

TECHNOLOGIES INC. CONFIDENTIAL AND PROPRIETARY

INFORMATION. DISCLOSURE, USE OR REPRODUCTION

WITHOUT THE WRITTEN AUTHORIZATION OF REMOTE

TECHNOLOGIES INC. IS STRICTLY PROHIBITED.

01 ----- ----- PRELIMINARY RELEASE DRF

WK-2 WATERPROOF

INSTALLATION

01

1 1

ASSEM . WK-2-TOTAL

RTI 01/07/15

°

STEP 3 - FOR WATERTIGHT INSTALLATION

APPLY 2ND LAYER OF CAULK AROUND PERIMETER

AFTER TOUCH PANEL IS INSTALLED.

DETAIL A

STEP 1 - TEST FIT REAR BOX IN

WALL OPENING AND REMOVE.

CAULK WALL OPENING WITH A BEAD

OF SILICONE OR PAINTABLE LATEX

SEALANT BEFORE INSTALLING.

STEP 2 - TEST FIT TOUCH SCREEN

IN REAR BOX CONTROLLER BOARD

ASSEMBLY. IF NEEDED ADJUST CONTROLLER

BOARD MOUNTING SCREWS TO LEVEL AND

CENTERED TOUCH PANEL AND TEST FIT AGAIN.

REMOVE ADHESIVE GASKET RELEASE LINER, ALIGN

CONNECTOR, LEVEL, CENTER VERTICALLY, HORIZONTALLY

AND SEAT INTO CONTROLLER BOARD. PRESS OUTSIDE

EDGES OF TOUCH SCREEN UNTIL ADHESIVE GASKET SEATS

TO BACK BOX LIP.

WK2 Rear Housing

Assembly

Controller Board

14 Pin connector

#4 Screws (2) for

adjusting Controller

Board alignment

Drywall

* Bead of sealant around

perimeter of opening for

waterproof installations

WK2 Rear Housing Installation - Front view

DOCUMENT NO.

REV

ECO

REVISION RECORD

DESCRIPTION

DRFT

A

B

C

D

1234

D

C

B

A

4 3 2 1

DATE

MM(INCH)

25.4MM=1 INCH

TOLERANCES EXCEPT AS NOTED

MM

0

±

.0

±

.00

±

ANGLES

±

MATERIAL

FINISH

INCHES

.0

±

.00

±

.000

±

DATE

DATE

DATE

DATE

DFTG

CHKD

MFG

APPVL

INTERPRET PER ANSI Y14.5

THIRD ANGLE PROJECTION

MODEL

TITLE

SIZE

DO NOT SCALE DRAWING

DET LISTS

YES

NO

SHT OF

REV

REMOTE TECHNOLOGIES INC.

SHAKOPEE, MN 55379

DOCUMENT NO.PART NO.

THIS IS AN UNPUBLISHED WORK CONTAINING REMOTE

TECHNOLOGIES INC. CONFIDENTIAL AND PROPRIETARY

INFORMATION. DISCLOSURE, USE OR REPRODUCTION

WITHOUT THE WRITTEN AUTHORIZATION OF REMOTE

TECHNOLOGIES INC. IS STRICTLY PROHIBITED.

01 ----- ----- PRELIMINARY RELEASE DRF

WK-2 WATERPROOF

INSTALLATION

01

1 1

ASSEM . WK-2-TOTAL

RTI 01/07/15

°

STEP 3 - FOR WATERTIGHT INSTALLATION

APPLY 2ND LAYER OF CAULK AROUND PERIMETER

AFTER TOUCH PANEL IS INSTALLED.

DETAIL A

STEP 1 - TEST FIT REAR BOX IN

WALL OPENING AND REMOVE.

CAULK WALL OPENING WITH A BEAD

OF SILICONE OR PAINTABLE LATEX

SEALANT BEFORE INSTALLING.

STEP 2 - TEST FIT TOUCH SCREEN

IN REAR BOX CONTROLLER BOARD

ASSEMBLY. IF NEEDED ADJUST CONTROLLER

BOARD MOUNTING SCREWS TO LEVEL AND

CENTERED TOUCH PANEL AND TEST FIT AGAIN.

REMOVE ADHESIVE GASKET RELEASE LINER, ALIGN

CONNECTOR, LEVEL, CENTER VERTICALLY, HORIZONTALLY

AND SEAT INTO CONTROLLER BOARD. PRESS OUTSIDE

EDGES OF TOUCH SCREEN UNTIL ADHESIVE GASKET SEATS

TO BACK BOX LIP.

OLED Display

Programmable Buttons

Drywall

* Bead of Sealant

around perimeter

for waterproof

installations

DOCUMENT NO.

REV

ECO

REVISION RECORD

DESCRIPTION

DRFT

A

B

C

D

1234

D

C

B

A

4 3 2 1

DATE

MM(INCH)

25.4MM=1 INCH

TOLERANCES EXCEPT AS NOTED

MM

0

±

.0

±

.00

±

ANGLES

±

MATERIAL

FINISH

INCHES

.0

±

.00

±

.000

±

DATE

DATE

DATE

DATE

DFTG

CHKD

MFG

APPVL

INTERPRET PER ANSI Y14.5

THIRD ANGLE PROJECTION

MODEL

TITLE

SIZE

DO NOT SCALE DRAWING

DET LISTS

YES

NO

SHT OF

REV

REMOTE TECHNOLOGIES INC.

SHAKOPEE, MN 55379

DOCUMENT NO.PART NO.

THIS IS AN UNPUBLISHED WORK CONTAINING REMOTE

TECHNOLOGIES INC. CONFIDENTIAL AND PROPRIETARY

INFORMATION. DISCLOSURE, USE OR REPRODUCTION

WITHOUT THE WRITTEN AUTHORIZATION OF REMOTE

TECHNOLOGIES INC. IS STRICTLY PROHIBITED.

01 ----- ----- PRELIMINARY RELEASE DRF

WK-2 WATERPROOF

INSTALLATION

01

1 1

ASSEM . WK-2-TOTAL

RTI 01/07/15

°

STEP 3 - FOR WATERTIGHT INSTALLATION

APPLY 2ND LAYER OF CAULK AROUND PERIMETER

AFTER TOUCH PANEL IS INSTALLED.

DETAIL A

STEP 1 - TEST FIT REAR BOX IN

WALL OPENING AND REMOVE.

CAULK WALL OPENING WITH A BEAD

OF SILICONE OR PAINTABLE LATEX

SEALANT BEFORE INSTALLING.

STEP 2 - TEST FIT TOUCH SCREEN

IN REAR BOX CONTROLLER BOARD

ASSEMBLY. IF NEEDED ADJUST CONTROLLER

BOARD MOUNTING SCREWS TO LEVEL AND

CENTERED TOUCH PANEL AND TEST FIT AGAIN.

REMOVE ADHESIVE GASKET RELEASE LINER, ALIGN

CONNECTOR, LEVEL, CENTER VERTICALLY, HORIZONTALLY

AND SEAT INTO CONTROLLER BOARD. PRESS OUTSIDE

EDGES OF TOUCH SCREEN UNTIL ADHESIVE GASKET SEATS

TO BACK BOX LIP.

Adhesive Gasket

14 Pin Connector

WK2 Glass Keypad Installation

WK2 Glass Keypad Assembly - Rear View

Water Resistant In-Wall Keypad

WK2 Glass Keypad

Assembly

Holes (4) used for

alternate mounting

methods (Use #4

athead screws)

WK2 Glass Keypad Assembly - Front View

Loading...

Loading...