Do you have a question about the Sacmi Imola CHS Series and is the answer not in the manual?

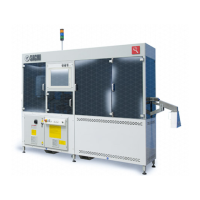

| Brand | Sacmi |

|---|---|

| Model | Imola CHS Series |

| Category | Industrial Equipment |

| Language | English |

Provides an overview of the manual's purpose and safety guidelines.

Instructions on manual storage and accessibility for operators.

Explains how information is organized and how to interpret symbols.

Defines roles like operator and maintenance worker.

Outlines warranty terms, conditions, and exclusions.

Lists supplementary documents included with the manual.

Explains various warning, danger, and alert signs used in the manual.

Details the identification plate on the machine.

States the machine's compliance with relevant European directives.

Overview of the CHS family machines and their purpose.

Lists the primary components of the CHS100 and CHS200 machines.

Describes the double roller spacer and optional turn-plate spacer.

Details the function and typical defects detected by the spark tester.

Explains the function of the standard conveyor belt.

Describes the overturned conveyor belt used in the CHS200.

Refers to other manuals for electrical cabinet information.

Details the components of the pneumatic system.

Explains the function of the optional diverter.

Describes the top inspection system for cap quality control.

Details the bottom inspection system for cap quality control.

Describes the optional 360° inspection system for cap wall analysis.

Defines intended use, prohibited operations, and misuse of the machine.

Provides overall dimensions for the CHS100.

Shows graphical representation and dimensions for CHS100.

Shows graphical representation and dimensions for CHS200.

Lists technical data for electrical and pneumatic systems.

Presents detailed technical specifications for the machines.

Provides technical data specific to the spark tester device.

Specifies permissible fluctuations in electrical and pneumatic variables.

Illustrates and describes the machine's rating plate.

Defines the type and dimensions of caps the machine can handle.

Details noise level measurements for CHS100.

Presents sound pressure level data for CHS100.

Presents sound pressure level data for CHS200.

Provides a data sheet template for machine configuration.

Introduces system diagrams.

Shows the pneumatic system diagram for CHS100.

Shows the pneumatic system diagram for CHS200.

Discusses the general safety devices installed on the machine.

Covers general safety standards and environmental conditions for operation.

Details specific safety devices like shutdown systems and emergency stops.

Explains the function of shutdown devices.

Describes how shutdown signals are communicated to the operator.

Lists guards and other devices protecting the operator.

Explains the usage and function of emergency stop buttons.

Provides guidelines for safely handling the machine.

Details safe procedures for lifting the machine.

Covers safe practices for moving the machine.

Outlines procedures for placing the machine after movement.

Specifies correct usage of lifting equipment.

General standards and requirements for machine installation.

Covers installation standards, space requirements, and grounding.

Emphasizes the need for trained personnel for operation.

Specifies company responsibilities for personnel training and PPE.

Defines operator qualifications and tasks.

Outlines requirements and tasks for maintenance personnel.

General safety standards for operating, adjusting, and maintaining the machine.

Key safety standards for operation, maintenance, and use of parts.

Warns about potential eye damage from bright lights.

Warns against accessing the cap exit area while the machine is running.

Discusses safety guards with mechanical locks and their security.

Advises on shutting off pneumatic systems before operation.

Warns against modifying pressure relief devices.

Introduces procedures for decommissioning and dismantling.

Outlines steps for safely decommissioning the machine.

Details procedures for dismantling the machine and recycling materials.

Covers procedures for shipping and handling the machine.

Explains how the machine is divided for shipping.

Notes that dimensions/weights are approximate.

Provides guidelines for handling machine parts.

Step-by-step instructions for assembling the machine.

General information on connecting the machine to power sources.

Details how to connect the machine to the pneumatic system.

Covers requirements for connecting the machine to the electrical system.

Provides instructions for connecting the main electric cables.

Explains how to make the ground connection for safety.

States that start-up is for trained personnel only.

Outlines the start-up procedure.

Lists essential checks before starting the machine.

Details steps for checking machine operation after start-up.

Describes the operation of the spark tester control panel.

Explains how the spark tester device works.

Describes the control panel and monitor for machine operations.

Illustrates and labels the main operator interface components.

Explains the meaning of the indicator tower lights.

Describes the operator interface for the spark tester.

Outlines different work cycles for the machine.

Details operations performed in manual mode.

Describes the normal automatic operating cycle.

Steps for restarting the machine in normal automatic mode.

Steps for changing product configuration in automatic mode.

Procedures for changing software and image settings.

Explains operation in remote automatic mode.

Covers normal shutdown procedures.

Steps for shutting down the machine during operation.

Details how to activate the emergency stop.

Steps to follow after an emergency shutdown.

Procedures for adjusting the vision system components.

Verifies sensor, encoder, and reject device functionality.

Verifies proper ejection of defective vs. good quality pieces.

Details how to test product inspection and rejection performance.

Adjustments for pneumatic system components like blowers.

Adjustments for the pneumatic control unit.

Step-by-step guide to adjusting system pressure.

Procedure for setting the pressure switch parameters.

Procedures for adjusting the machine for different cap sizes.

Instructions for adjusting the 2-wheel spacer for cap size.

Details how to adjust the turn-plate spacer for cap operation.

Adjusts cylinder YV3 and timing sensor SQ6 for accurate cap timing.

Adjusts the turn-plate for the spark tester.

Adjusts blowers and nozzles for cap handling.

Adjustments for the overturned conveyor belt in CHS200.

Adjusts the optional diverter for cap deflector.

Details positioning of the cap slide plate.

Adjusts the reject conveyor height and band.

Shows locations of various sensors on the machine.

Adjustments for camera positioning, focus, and brightness.

General safety rules and precautions for maintenance operations.

Outlines routine maintenance tasks and schedules.

A table detailing routine maintenance tasks, intervals, and actions.

Specific routine maintenance tasks to be performed.

Instructions for cleaning optical components.

Procedure for cleaning conveyor belts.

Steps for checking and adjusting conveyor belt tension.

Detailed steps for replacing the conveyor belt.

Instructions for cleaning or replacing the pneumatic filter.

Procedure for cleaning electrical cabinets and fans.

How to check the spark tester device brush functionality.

Checks the function of a specific safety microswitch.

States that special maintenance requires expert personnel.

Provides torque specifications for nuts and bolts.

Lists common problems, causes, and remedies.

Provides troubleshooting guidance for machine issues.

Outlines steps for safely decommissioning the machine.

Details procedures for dismantling the machine and recycling materials.